A kind of copper alloy hairspring material and preparation method thereof

A copper alloy and hairspring technology, which is applied in metal rolling, gyroscope/steering sensing equipment, instruments, etc., can solve the difficulty in meeting the finished product size and tolerance requirements, high mechanical and conductive performance requirements, poor consistency and stability, etc. problems, to achieve the effect of being conducive to mass production, simple and easy preparation method, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

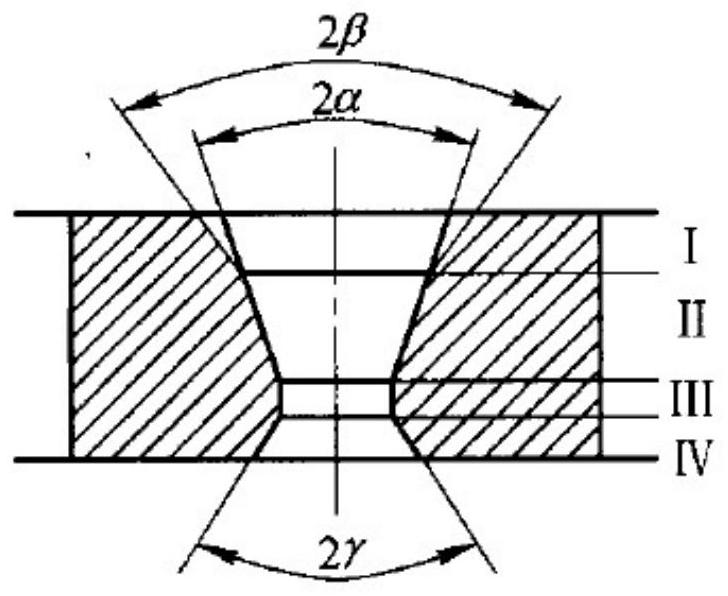

Method used

Image

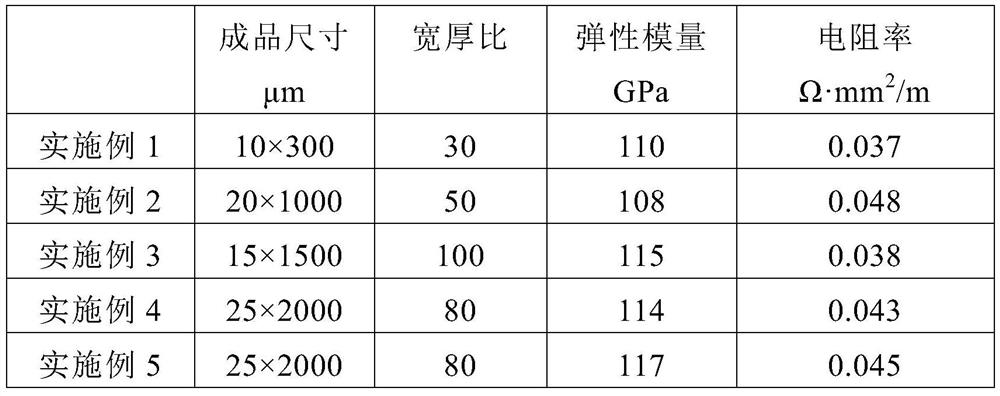

Examples

Embodiment 1

[0069] Example 1: Preparation of Be2Ni0.3Zn2Sn2Cu copper alloy hairspring material

[0070] The design furnace capacity is 5.00kg.

[0071] Weigh 0.88kg of Cu, 0.12kg of Be, 0.8kg of Cu, and 0.2kg of Sn, respectively, and put them into a vacuum intermediate frequency melting furnace, and evacuate to 8.0×10 -2 Pa, after the metal is fully melted, put it into water quickly to prepare 1kgCu-Be master alloy and 1kgCu-Sn master alloy respectively.

[0072] Weigh 3.55 kg of Cu, 0.833 kg of Cu-Be intermediate, 0.5 kg of Cu-Sn intermediate, 0.1 kg of Zn, and 0.015 kg of Ni, and put them into the graphite crucible of the non-vacuum melting furnace, and use medium frequency induction melting, metal Add covering agent after complete melting, the melting temperature is 1211°C, and the casting speed is 3mm / s. A billet with a diameter of 10.0 mm and a length of about 0.7 m was cast.

[0073] The prepared billet is swaged, and the single-pass processing rate is between 10.3% and 12.5%, an...

Embodiment 2

[0078] Example 2: Preparation of Be1Ni0.3Zn3Sn3Cu copper alloy hairspring material

[0079] The design furnace capacity is 4.92kg.

[0080] Weigh 0.36kg of Cu, 0.05kg of Be, 0.59kg of Cu, and 0.15kg of Sn, respectively, and put them into a vacuum intermediate frequency melting furnace, and evacuate to 8.0×10 -2 Pa, after the metal is completely melted, put it into water quickly to prepare 0.41kg Cu-Be master alloy and 0.74kg Cu-Sn master alloy respectively.

[0081] Weigh 3.61 kg of Cu, 0.41 kg of Cu-Be intermediate, 0.74 kg of Cu-Sn intermediate, 0.15 kg of Zn, and 0.015 kg of Ni, and put them into the graphite crucible of the non-vacuum melting furnace, and use medium frequency induction melting, metal Add the covering agent after full melting, the melting temperature is 1238°C, and the casting speed is 5mm / s. Cast a billet with a diameter of 8.0mm and a length of about 1.1m.

[0082] The prepared billet is swaged, and the single-pass processing rate is between 11.0% and ...

Embodiment 3

[0087] Example 3: Preparation of Be2Ni0.3Zn2Sn2Cu copper alloy hairspring material

[0088] The design furnace capacity is 5.00kg.

[0089] Weigh 0.88kg of Cu, 0.12kg of Be, 0.8kg of Cu, and 0.2kg of Sn, respectively, and put them into a vacuum intermediate frequency melting furnace, and evacuate to 8.0×10 -2 Pa, after the metal is fully melted, put it into water quickly to prepare 1kgCu-Be master alloy and 1kgCu-Sn master alloy respectively.

[0090]Weigh 3.55kg of Cu, 0.833kg of Cu-Be intermediate, 0.5kg of Cu-Sn intermediate, 0.1kg of Zn, and 0.015kg of Ni, and put them into the graphite crucible of the non-vacuum melting furnace, adopt medium frequency induction melting, metal Add covering agent after complete melting, the melting temperature is 1287°C, and the casting speed is 3mm / s. A billet with a diameter of 10.0 mm and a length of about 0.7 m was cast.

[0091] The prepared billet is swaged, and the single-pass processing rate is between 10.3% and 12.5%, and proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com