Preparation process of flame-retardant polyester resin and application of flame-retardant polyester resin in flame-retardant coatings

A technology of flame retardant polyester and preparation process, applied in polyester coatings, fire retardant coatings, coatings, etc., can solve problems such as changes in coating properties, changes in resin structure, and reduction in flame retardant properties of coatings, and achieves high activity and strong performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

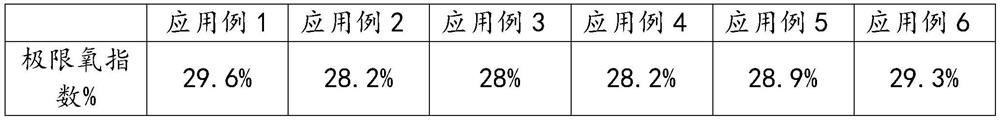

Examples

Embodiment 1

[0031] The specific preparation process of flame retardant reinforcing agent is as follows:

[0032] Step 1: Add 265mL of acetone, 283g of cupric chloride and 72g of isobutyraldehyde into the reaction kettle, stir and react at 8°C for 83h, then heat to evaporate the solvent and cool down to 0°C, then filter and recover cuprous chloride to obtain chlorinated Isobutyraldehyde; Chloroisobutyraldehyde 1 HNMR spectrum analysis, δ=1.75ppm is -CH 3 group 1 Absorption peak of H, δ=9.72ppm aldehyde group 1 H absorption peak;

[0033] Step 2: Add 500mL of benzene and 1mol of dimethyl phosphite into the reaction kettle at the same time, and then add a methanol solution of sodium methoxide to it. The amount of sodium methoxide added is 1mol. After stirring evenly, the temperature is raised to 60°C, and 0.98mol of N- Allylmethylamine, control the dropwise addition within 1 hour, reflux reaction for 4 hours after the addition, then adjust the pH of the solution to 7-7.5, then add the pr...

Embodiment 2

[0037] The specific preparation process of brominated adipic acid is as follows: Add 1 mol of adipic acid into 150 mL of benzene and stir to dissolve, then raise the temperature to 80°C, add 100 mL of bromine and 4.8 mL of phosphorus trichloride dropwise, and heat the reaction until no longer Red bromine liquid vapor appears, then slowly raise the temperature to 100°C and keep it warm for 4 hours, then carry out vacuum distillation and cooling crystallization on the product to obtain brominated adipic acid; brominated adipic acid 1 Spectrum analysis of HNMR, δ=4.23ppm and δ=12.22ppm are carboxyl groups 1 H absorption peak.

Embodiment 4

[0039] The specific preparation process of dihydroxyacetophenone is as follows: 1mol of 4-aminoacetophenone, 50mL of acetic acid solution with a mass concentration of 35% and 160mL of ethanol are simultaneously added to the reactor and stirred to dissolve, and then 2.4mol of Propylene oxide, control the dropwise addition within 2 hours, then raise the temperature to 30°C for 2 hours, then raise the temperature to 110°C for 7 hours, and remove unreacted propylene oxide and solvent by rotary evaporation to obtain dihydroxyacetophenone; Keto 1 Spectrum analysis of HNMR, δ=2.5ppm and δ=5.37ppm are -CH in the benzene ring connected to the ethyl ketone group 3 and hydroxyl 1 H absorption peak;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com