Pipeline anti-corrosion treatment facility

An anti-corrosion treatment and pipeline technology, which is applied in metal processing equipment, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of inability to realize fast clamping adjustment structure bump protection, and inability to achieve synchronous realization Problems such as cleaning residues attached to the outer wall of the pipe after grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] as attached figure 1 to attach Figure 8 Shown:

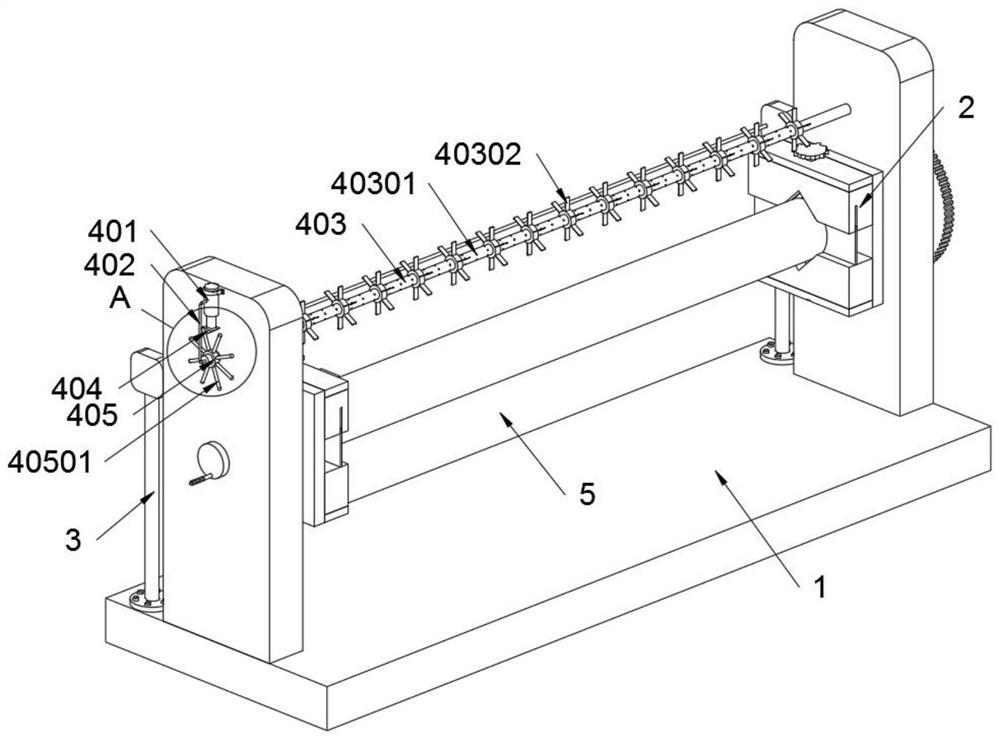

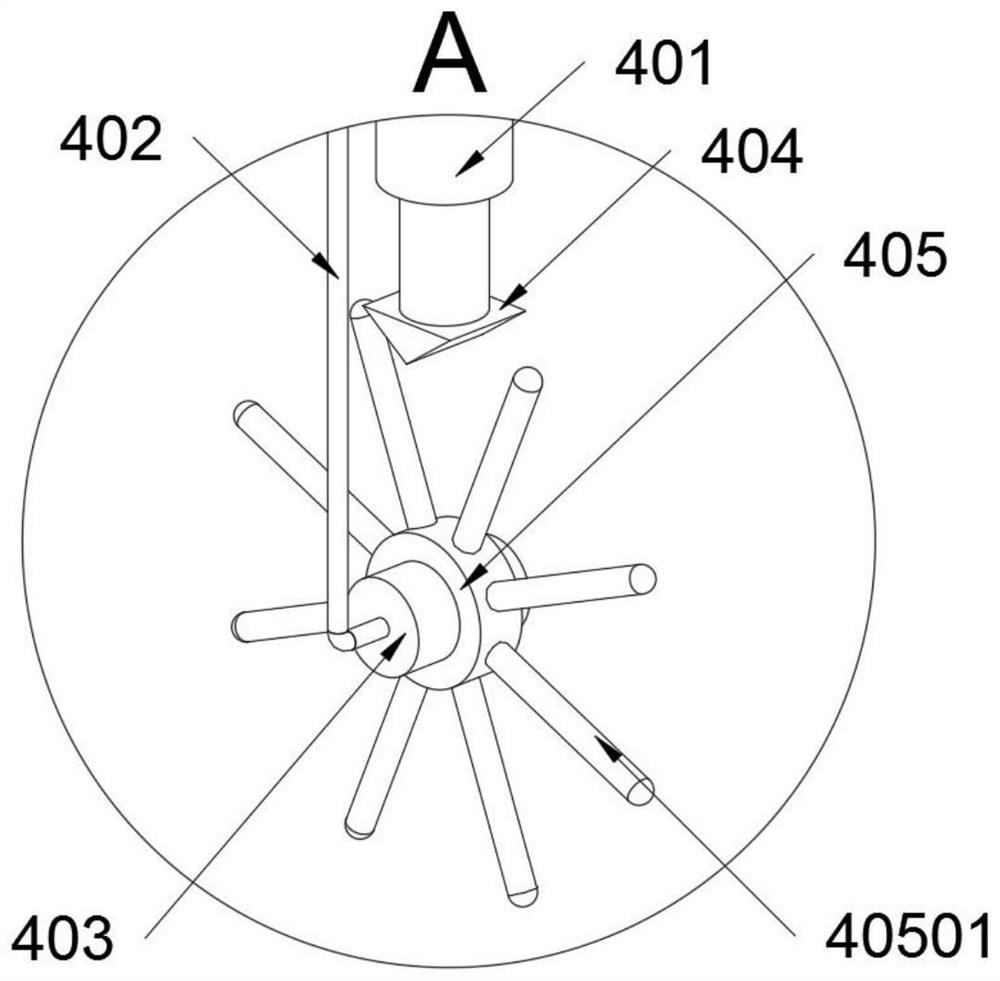

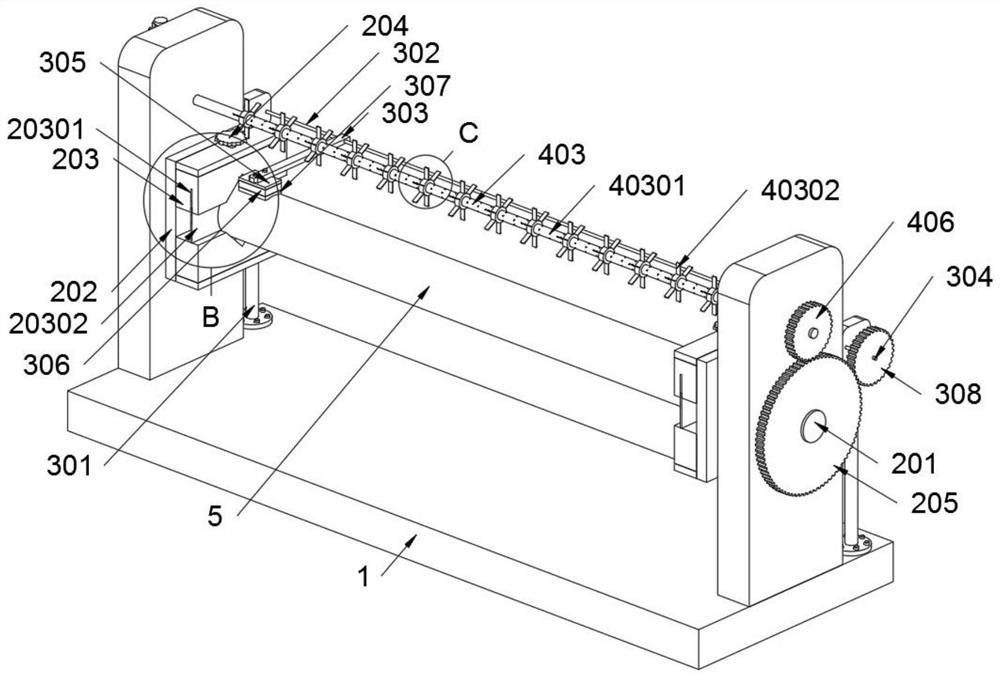

[0035]The present invention provides a pipe anticorrosion treatment equipment, which includes a main body seat 1; two clamp structures 2 are installed on the main body seat 1, and a grinding structure 3 is installed on the main body seat 1, and a pipe 5 is clamped on the clamp structure 2; An auxiliary structure 4 is installed on the main body seat 1; refer to as figure 1 with figure 2 , the auxiliary structure 4 includes a force block 404, a toggle seat 405 and a toggle bar 40501, the force block 404 is welded on the head end of the elastic telescopic bottle 401; the toggle seat 405 is installed on the nozzle pipe 403, and the toggle seat 405 Toggle lever 40501 is welded in a circular array on the top; the toggle lever 40501 is in contact with the force-bearing block 404, and the force-bearing block 404 is a triangular columnar structure, so that when the toggle seat 405 drives the toggle lever 40501 to rotate, elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com