Method for preparing nano-composite polyvinylidene fluoride hollow fiber membrane by three-layer co-extrusion and co-extrusion equipment

A technology of polyvinylidene fluoride and polyvinylidene fluoride resin, which is applied in the field of three-layer co-extrusion to prepare nanocomposite polyvinylidene fluoride hollow fiber membranes, which can solve the problems of stability, poor modification effect and complicated modification process, etc. problem, to achieve the best modification effect, not easy to fall off, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

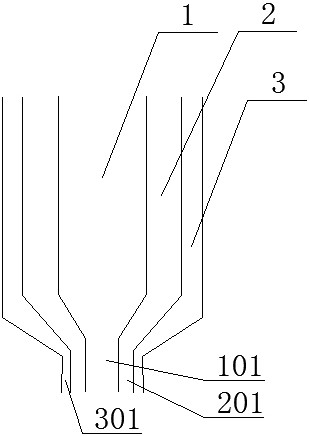

Image

Examples

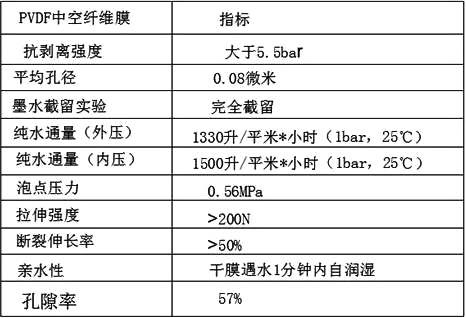

Embodiment 1

[0025]1) At 30°C, dissolve polyvinylidene fluoride resin with a mass fraction of 15wt% and additives with a mass fraction of 5wt% in a solvent or diluent with a mass fraction of 80wt%, and then defoam to obtain a polyvinylidene fluoride casting solution; The polyvinylidene fluoride resin is polyvinylidene fluoride powder with a weight average molecular weight of 300,000. The additives are polyethylene glycol with a molecular weight of 200-20,000, polyvinylpyrrolidone with a molecular weight of 10,000-100,000, polyoxyethylene-polyoxypropylene-polyoxyethylene with a molecular weight of 1000-16,000, nonylphenol polyoxyethylene ether, glycerin, One or more mixtures of sorbitan laurate. The solvent or diluent is N,N-dimethylacetamide, N,N-dimethylformamide, N-methylpyrrolidone, dimethyl sulfoxide, triethyl phosphate, diphenyl carbonate, Propylene carbonate, dimethyl terephthalate, diethyl terephthalate, dibutyl terephthalate, dioctyl terephthalate, glyceryl triacetate, benzophenon...

Embodiment 2

[0031] 1) At 100°C, dissolve polyvinylidene fluoride resin with a mass fraction of 20wt% and additives with a mass fraction of 8wt% in a solvent or diluent with a mass fraction of 72wt%, and then defoam to obtain a polyvinylidene fluoride casting solution ; The polyvinylidene fluoride resin is a polyvinylidene fluoride powder with a weight average molecular weight of 400,000.

[0032] 2) A nano-functional material solution was prepared by uniformly dispersing nano-silica with a mass fraction of 1 wt% in a polyvinylidene fluoride solution with a mass fraction of 1 wt%.

[0033] 4) The polyvinylidene fluoride hollow fiber membrane embryo body is immersed in a coagulation bath at a temperature of -5°C to undergo phase inversion.

[0034] Other steps are the same as in Example 1.

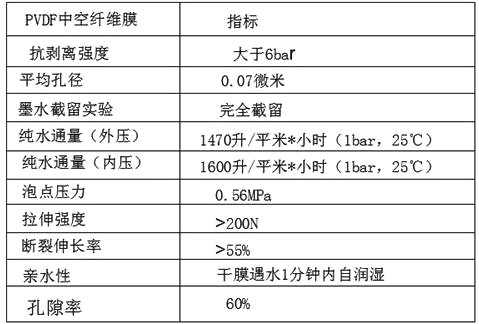

Embodiment 3

[0036] 1) At 150°C, dissolve polyvinylidene fluoride resin with a mass fraction of 20wt% and additives with a mass fraction of 10wt% in a solvent or diluent with a mass fraction of 70wt%, and then defoam to obtain a polyvinylidene fluoride casting solution; The polyvinylidene fluoride resin is polyvinylidene fluoride pellets with a weight average molecular weight of 500,000. The additive is a mixture of polyethylene glycol with a molecular weight of 2000 and polyvinylpyrrolidone with a molecular weight of 30000, and the solvent or diluent is a mixture of N-methylpyrrolidone, dioctyl terephthalate and tributyl citrate.

[0037] 2) Uniformly disperse nano titanium dioxide with a mass fraction of 8wt% in a polyvinylidene fluoride solution with a mass fraction of 2wt% to prepare a nano functional material solution; the polyvinylidene fluoride solution is a dilute solution composed of a solvent and polyvinylidene fluoride Solution, the polyvinylidene fluoride resin used has a weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com