Hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and catalyst technology, which are applied in the directions of catalyst activation/preparation, catalyst, carbon compound catalyst, etc., can solve the problems of serious environmental pollution, poor catalyst stability, low cumene selectivity, etc., and improve the cumene selectivity. The effect of improving the selectivity, reducing the cost of post-separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

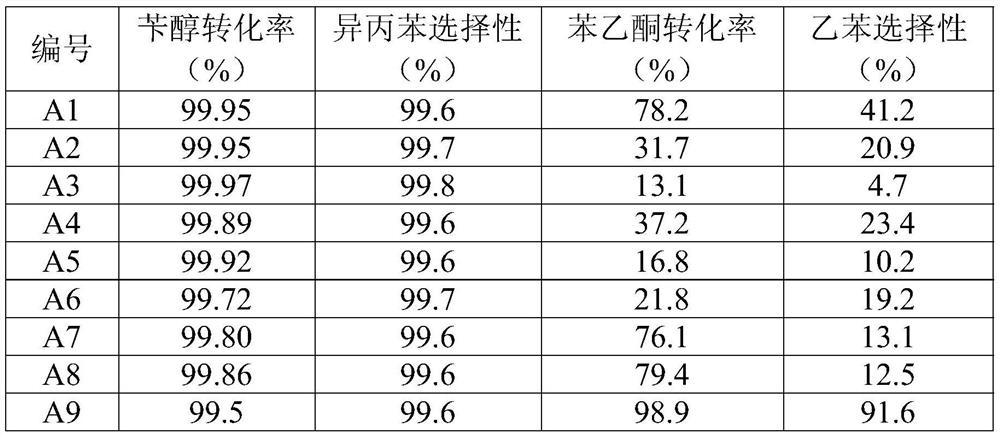

Embodiment 1

[0047] Weigh 0.5gPdCl 2 and 2.5 g of glucose were dissolved in a prepared solution containing 10.0 g of concentrated hydrochloric acid, 5.0 g of citric acid and 100 g of water, and the pH value of the solution was adjusted to 3 with lye to obtain a Pd impregnation solution. Heat the impregnating solution to 80°C, weigh 25g of alumina carrier, immerse it in the Pd impregnating solution, stir it thoroughly for 10min, filter it, wash it with deionized water, dry it at 100°C for 12h, and place it in a muffle furnace (nitrogen atmosphere ) at 500°C for 4 hours to obtain catalyst A1. The main composition of catalyst A1 is shown in Table 2.

Embodiment 2

[0049] Weigh 0.5gPdCl 2 and 5.0 g of glucose were dissolved in a prepared solution containing 10.0 g of concentrated hydrochloric acid, 5.0 g of citric acid and 100 g of water, and the pH value of the solution was adjusted to 3 with lye to obtain a Pd impregnation solution. Heat the impregnating solution to 80°C, weigh 25g of alumina carrier, immerse it in the Pd impregnating solution, stir it thoroughly for 10min, filter it, wash it with deionized water, dry it at 100°C for 12h, and place it in a muffle furnace (nitrogen atmosphere ) at 500° C. for 4 h to obtain catalyst A2. The main composition of catalyst A2 is shown in Table 2.

Embodiment 3

[0051] Weigh 0.5gPdCl 2 and 10.0 g of glucose were dissolved in a prepared solution containing 10.0 g of concentrated hydrochloric acid, 5.0 g of citric acid and 100 g of water, and the pH value of the solution was adjusted to 3 with lye to obtain a Pd impregnation solution. Heat the impregnating solution to 80°C, weigh 25g of alumina carrier, immerse it in the Pd impregnating solution, stir it thoroughly for 10min, filter it, wash it with deionized water, dry it at 100°C for 12h, and place it in a muffle furnace (nitrogen atmosphere ) at 500° C. for 4 h to obtain catalyst A3. The main composition of catalyst A3 is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com