Outer rotor water cooling structure of permanent magnet synchronous hub motor

A hub motor and permanent magnet synchronous technology, applied in the direction of magnetic circuit shape/style/structure, cooling/ventilation device, magnetic circuit rotating parts, etc., can solve the problems affecting the safe and stable operation of the motor, the internal heat is difficult to discharge, and the permanent magnet is irreversible Demagnetization and other problems, to avoid irreversible demagnetization, simple manufacturing and assembly process, avoid the effect of magnetic performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

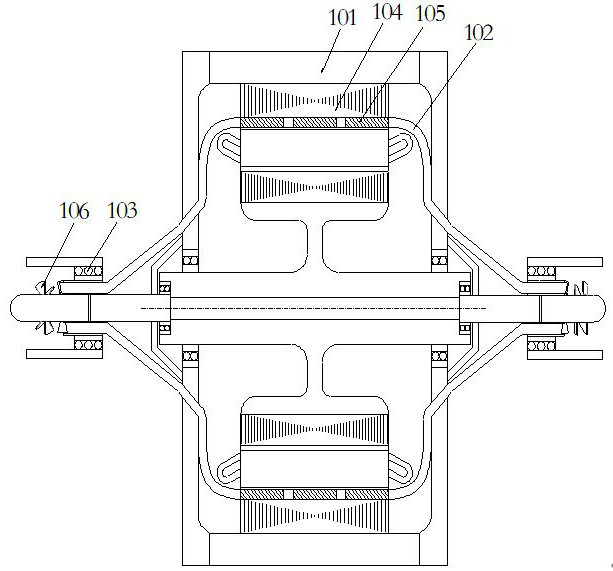

[0018] Such as figure 1 As shown, an outer rotor water-cooled cooling structure of a permanent magnet synchronous hub motor includes an outer rotor permanent magnet synchronous hub motor 101, an outer rotor water cooling pipe 102, a waterproof bearing 103 and an axial flow impeller 106; the outer rotor water cooling pipe 102 is welded between the inner ring 103 of the waterproof bearing and the outer surface of the shaft of the axial flow impeller 106, passes through the inside of the hub motor 101, and is in close contact with the periphery of the permanent magnet 105 and the inner wall of the rotor core 104. Seen from the left end, when the outer rotor hub motor 101 rotates clockwise, it drives the outer rotor water cooling pipe 102 and the axial flow impeller 106 to rotate, and the cooling water passes through the axial flow impeller 106 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com