Complex-phase magnetic material and preparation method thereof

A technology of magnetic materials and magnetic particles, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve problems such as unfavorable performance, weak binding force, and reduced magnetic properties of materials to achieve excellent insulation properties and Magnetic properties, excellent AC soft magnetic properties, and the effect of avoiding the reduction of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Raw material preparation

[0038] The raw material is gas atomized iron powder with an average diameter of 37 μm;

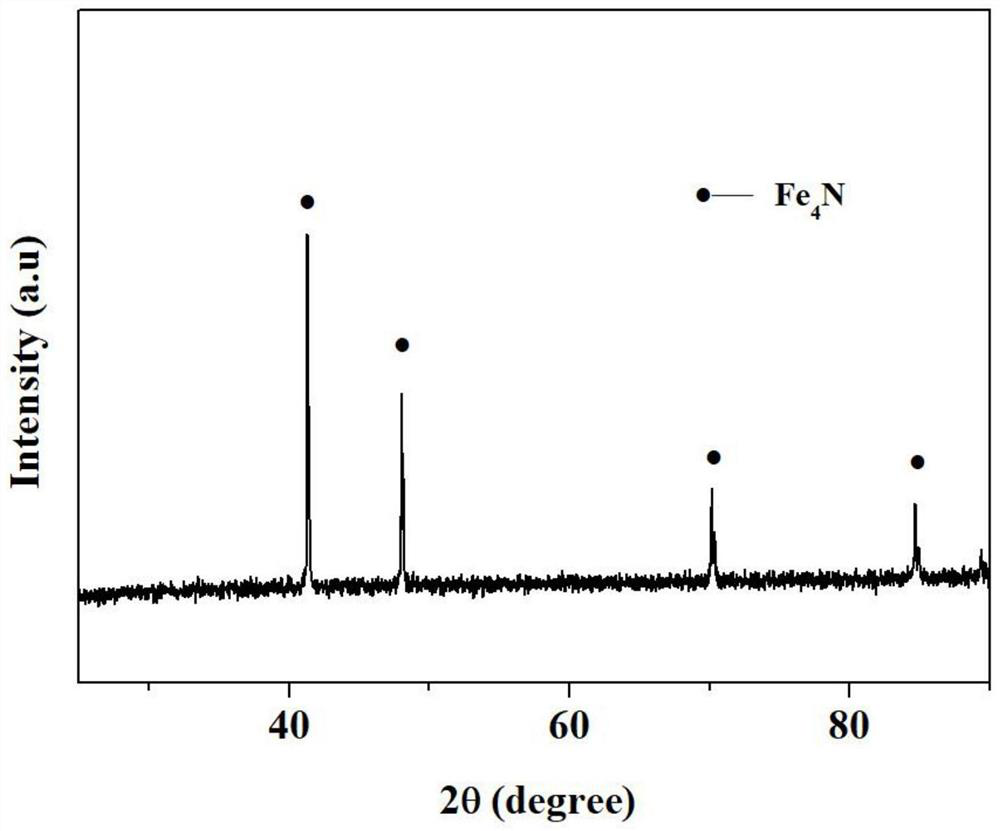

[0039]2) Preparation of Fe by high temperature nitriding 4 N magnetic particles

[0040] Iron powder in NH 3 :H 2 = In a mixed atmosphere of 1:1, nitriding at 550°C for 8 hours to obtain pure Fe 4 N-phase;

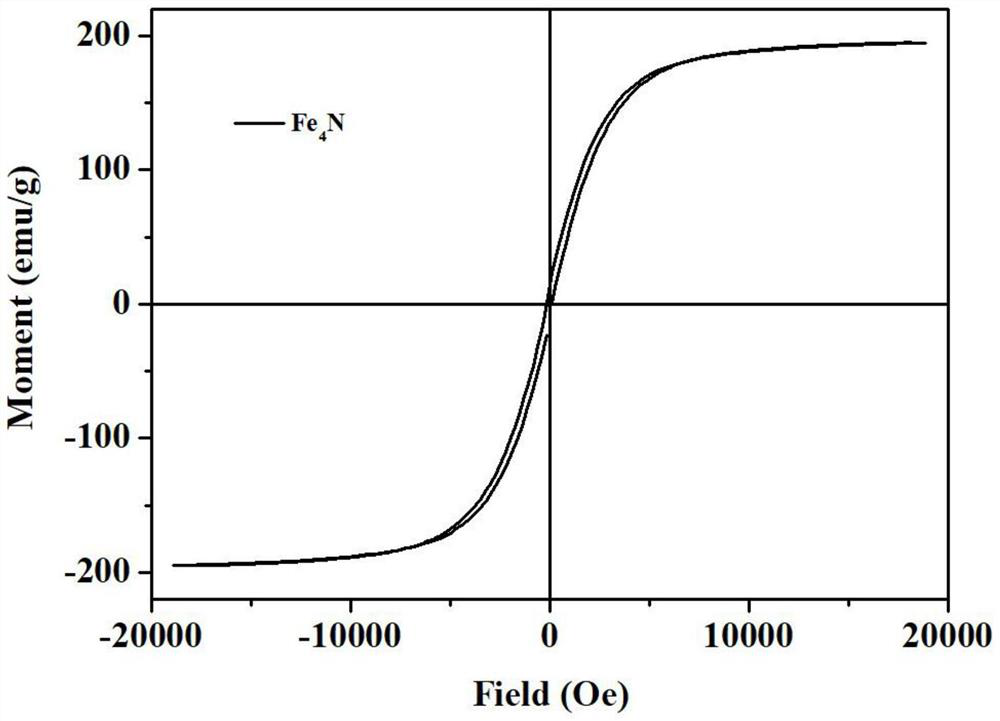

[0041] 3) Preparation of Fe by high temperature nitriding 4 N / Fe 3 N complex magnetic particles

[0042] The Fe obtained by nitriding 4 N particles, further in NH 3 Nitriding at 500°C for 5h in the atmosphere, and then cooling to room temperature with the furnace in an argon atmosphere to obtain Fe 4 N / Fe 3 N complex phase magnetic particles.

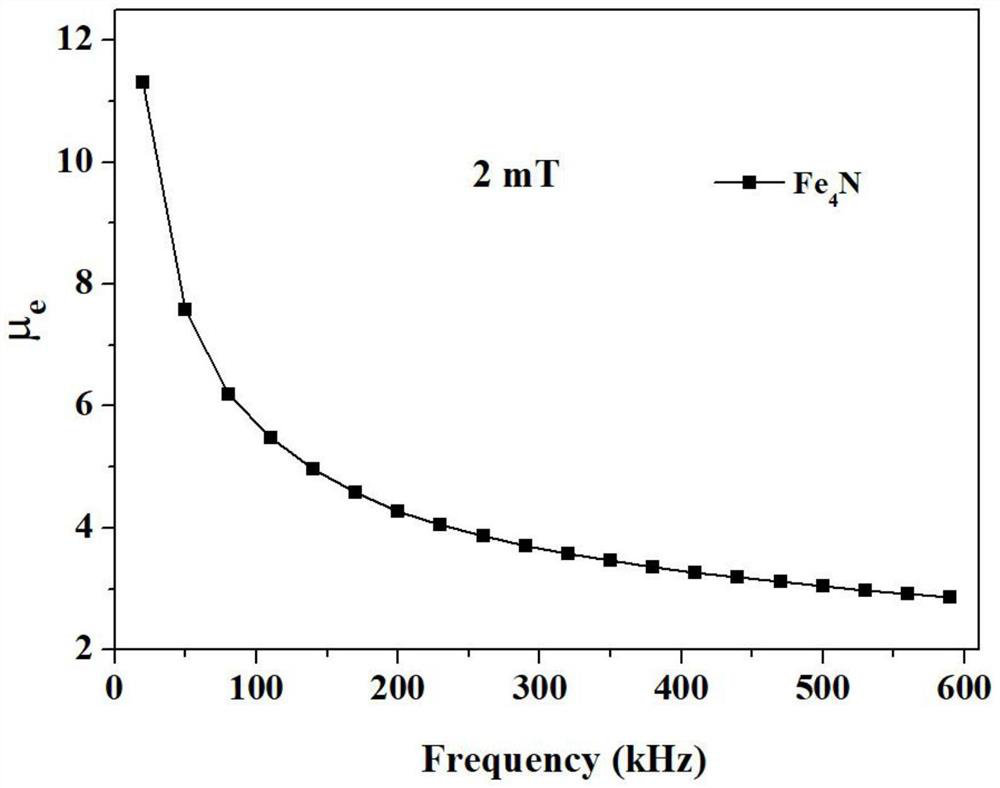

[0043] 4) Compression molding

[0044] Will Fe 4 N / Fe 3 N complex phase magnetic particles are evenly mixed with the binder PVP, and pressed under a pressure of 1.2GPa;

[0045] 5) Stress relief annealing

[0046] The pressed soft magnetic composite material is annealed and heat-treated in an...

Embodiment 2

[0057] 1) Raw material preparation

[0058] The raw material is water atomized iron powder with an average diameter of 80 μm;

[0059] 2) Preparation of Fe by high temperature nitriding 4 N magnetic particles

[0060] Iron powder in NH 3 :H 2 = In a mixed atmosphere of 1:1, nitriding at 550°C for 8 hours to obtain pure Fe 4 N-phase;

[0061] 3) Preparation of Fe by high temperature nitriding 4 N / Fe 3 N complex magnetic particles

[0062] The Fe obtained by nitriding 4 N particles, further in NH 3 Nitriding at 500°C for 12 hours in the atmosphere, and then cooling to room temperature with the furnace in the nitrogen atmosphere to obtain Fe 4 N / Fe 3 N complex phase magnetic particles.

[0063] 4) Compression molding

[0064] Will Fe 4 N / Fe 3 N complex phase magnetic particles are uniformly mixed with binder W-6C, and pressed under a pressure of 1.2GPa;

[0065] 5) Stress relief annealing

[0066] The pressed soft magnetic composite material is annealed and heat-...

Embodiment 3

[0070] 1) Raw material preparation

[0071] The raw material is carbonyl iron powder with an average diameter of 2 μm;

[0072] 2) Preparation of Fe by high temperature nitriding 4 N magnetic particles

[0073] Iron powder in NH 3 :H 2 = In a mixed atmosphere of 1:1, nitriding at 550°C for 8 hours to obtain pure Fe 4 N-phase;

[0074] 3) Preparation of Fe by high temperature nitriding 4 N / Fe 3 N complex magnetic particles

[0075] The Fe obtained by nitriding 4 N particles, further in NH 3 Nitriding at 500°C for 0.1h in the atmosphere, and then cooling to room temperature with the furnace in an argon atmosphere to obtain Fe 4 N / Fe 3 N complex phase magnetic particles.

[0076] 4) Compression molding

[0077] Will Fe 4 N / Fe 3 N complex phase magnetic particles are evenly mixed with adhesive modified epoxy resin, and pressed under 1.2GPa pressure;

[0078] 5) Stress relief annealing

[0079] The pressed soft magnetic composite material is annealed and heat-treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com