Ferrite-coated FeSiAl metal magnetic powder core and preparation method thereof

A technology of ferrite and magnetic powder cores, applied in the field of ferrite-coated FeSiAl metal magnetic powder cores and its preparation, can solve the problems of easy cracking of the Mn-Zn ferrite insulating layer, increased eddy current loss, and reduced energy consumption , to achieve the effect of reducing magnetic dilution, reducing magnetic dilution, and solving the effect of large eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

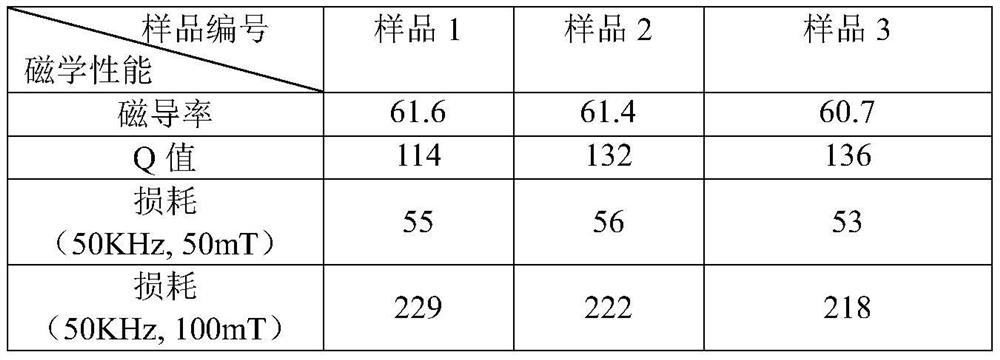

Embodiment 1

[0039] (1) Mix FeSiAl metal soft magnetic powder with FeCl 2 mixed with the aqueous solution of FeSiAl, heated to 80 °C, heated and stirred for 20 min, so that a layer of soluble FeCl was formed on the surface of FeSiAl metal soft magnetic powder. 2 , and dried at 90℃ for 20min to obtain FeSiAl metal soft magnetic powder@FeCl 2 ;Based on the total mass of FeSiAl metal soft magnetic powder, FeCl 2 The addition amount is 1wt%;

[0040] (2) The FeSiAl metal soft magnetic powder obtained in step (1) @FeCl 2 Mix with NaOH solution, stir evenly at room temperature (20°C), and dry at 90°C for 20 minutes to obtain insulating metal soft magnetic powder; based on the total mass of FeSiAl metal soft magnetic powder, the amount of NaOH added is 2wt%;

[0041] (3) Mix the insulating metal soft magnetic powder obtained in step (2) with epoxy resin and zinc stearate uniformly, press and form under 1500MPa pressure to obtain a blank with an outer diameter of 33.00mm, an inner diameter of 1...

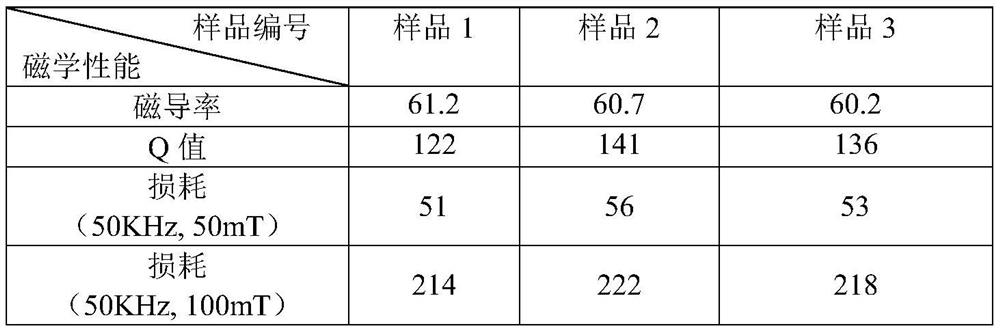

Embodiment 2

[0045] (1) Mix FeSiAl metal soft magnetic powder with FeCl 2 mixed with the aqueous solution of FeSiAl metal powder, heated to 100 °C, heated and stirred for 40 min, so that a layer of soluble FeCl was formed on the surface of FeSiAl metal soft magnetic powder. 2 , and dried at 120 °C for 40 min to obtain FeSiAl metal soft magnetic powder@FeCl 2 ;Based on the total mass of FeSiAl metal soft magnetic powder, FeCl 2 The addition amount is 3wt%;

[0046] (2) The FeSiAl metal soft magnetic powder obtained in step (1) @FeCl 2 Mix with NaOH solution, stir evenly at room temperature (40°C), and dry at 120°C for 40 minutes to obtain insulating metal soft magnetic powder; based on the total mass of FeSiAl metal soft magnetic powder, the amount of NaOH added is 3wt%;

[0047] (3) Mixing the insulating metal soft magnetic powder obtained in step (2) with epoxy resin and zinc stearate uniformly, press molding under 2000MPa pressure to obtain a blank with an outer diameter of 33.00mm, a...

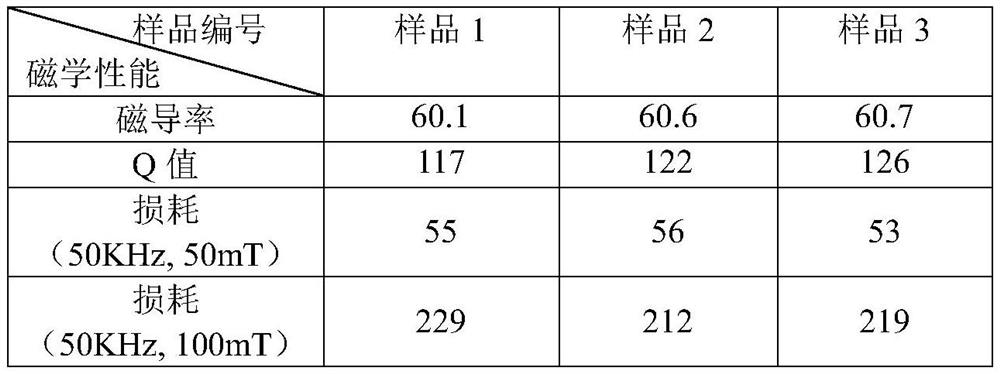

Embodiment 3

[0051] (1) The FeSiAl metal soft magnetic powder and FeSO 4 mixed with the aqueous solution of FeSiAl, heated to 80 °C, heated and stirred for 20 min to form a layer of soluble FeSO on the surface of FeSiAl metal soft magnetic powder 4 , and dried at 90℃ for 20min to obtain FeSiAl metal soft magnetic powder@FeSO 4 ;Based on the total mass of FeSiAl metal soft magnetic powder, FeSO 4 The addition amount is 1wt%;

[0052] (2) The FeSiAl metal soft magnetic powder obtained in step (1) @FeCl 2 Mix with KOH solution, stir evenly at room temperature, and dry at 90°C for 20 minutes to obtain insulating metal soft magnetic powder; based on the total mass of FeSiAl metal soft magnetic powder, the amount of KOH added is 2wt%;

[0053] (3) Mixing the insulating metal soft magnetic powder obtained in step (2) with water glass, barium stearate and zinc stearate uniformly, and pressing under pressure of 1500~2000MPa to obtain an outer diameter of 33.00mm and an inner diameter of 19.90mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com