Method for converting coal seam gas by adopting novel catalyst

A coal seam gas and catalyst technology, applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve problems affecting production efficiency, reduction of extraction effect, impact on coal mining environment, etc., to improve gas drainage efficiency, gas drainage The effect of improving efficiency and improving safety of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

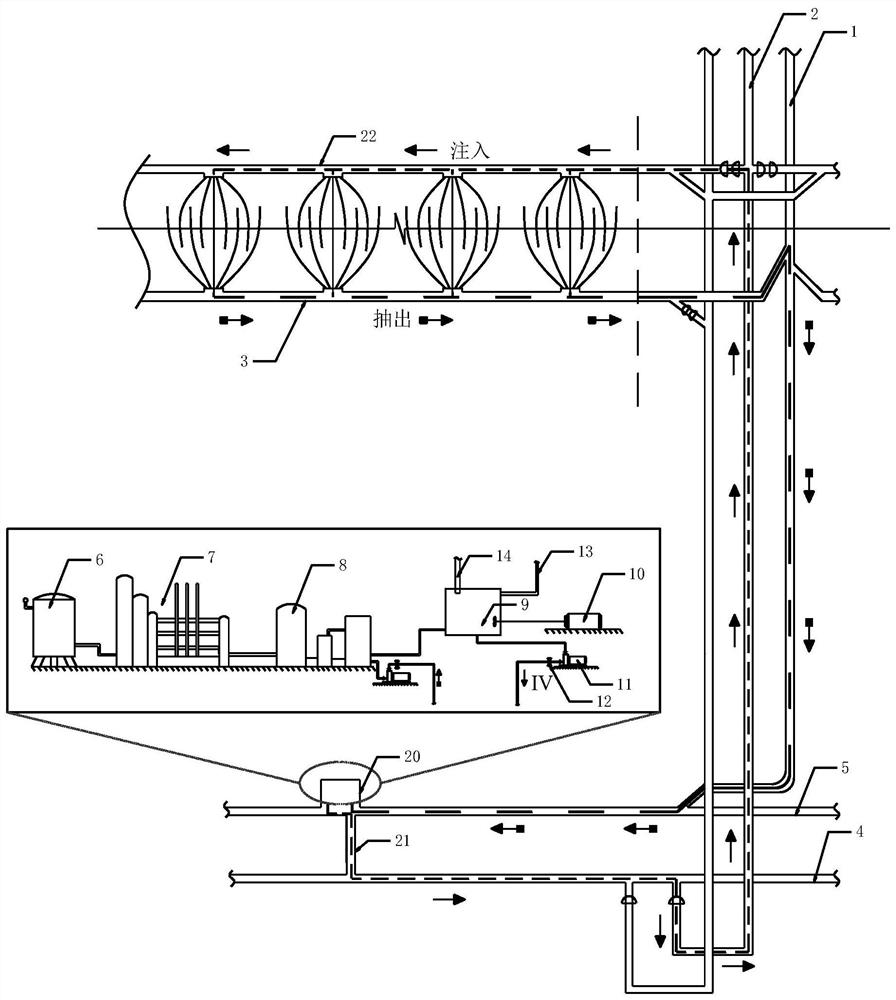

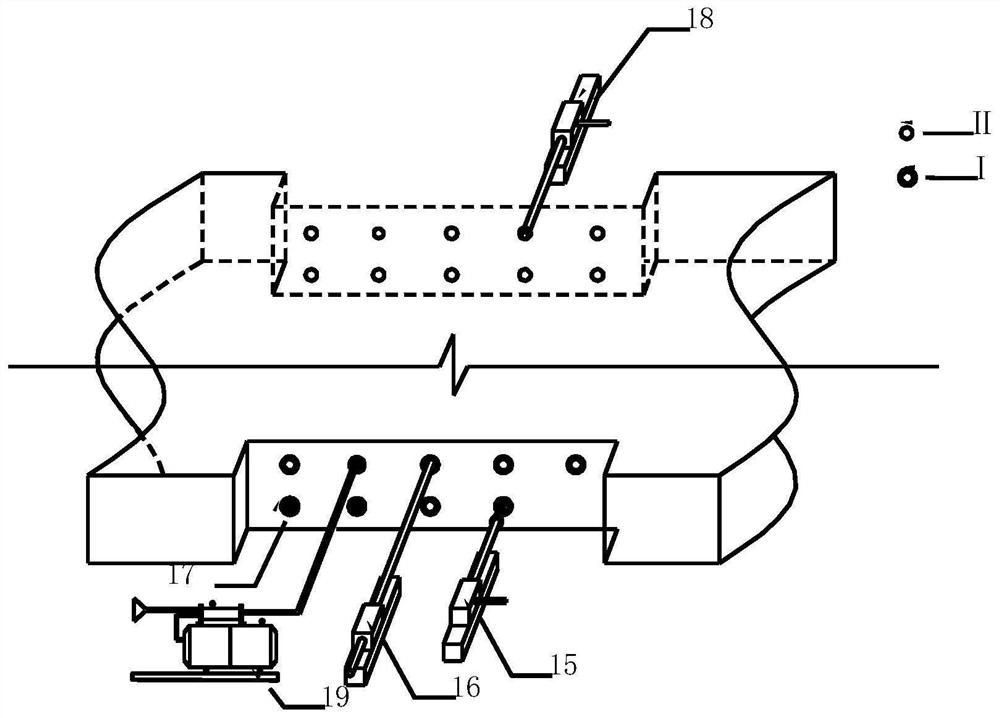

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] This embodiment provides a method for converting coal seam gas using a new catalyst, including: (1) arranging a series of drilling sites in the coal seam to be mined, and arranging bedding drilling holes to the coal seam through the drilling sites; The solution containing the catalyst is injected into the coal seam to be mined along the borehole, and the gas in the coal seam is catalyzed into methanol and dissolved in the catalyst solution; (3) The catalyst solution containing methanol is extracted from the coal seam through the pumping equipment, and the gas is extracted from the coal seam through the underground separation system. The methanol is separated from the catalyst solution, and the separated catalyst solution is injected into the coal again to realize the recycling of the catalyst solution, and the methanol solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com