Reservoir area bridge pile foundation scouring protection method and composite protection structure

A composite protective structure and pile foundation technology, which is applied in the direction of foundation structure engineering, foundation structure repair, sheet pile wall, etc., can solve the problems such as the serious impact on the safety of bridges and potential safety hazards, and achieve no need for maintenance time and improve the durability of the structure sex, good energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

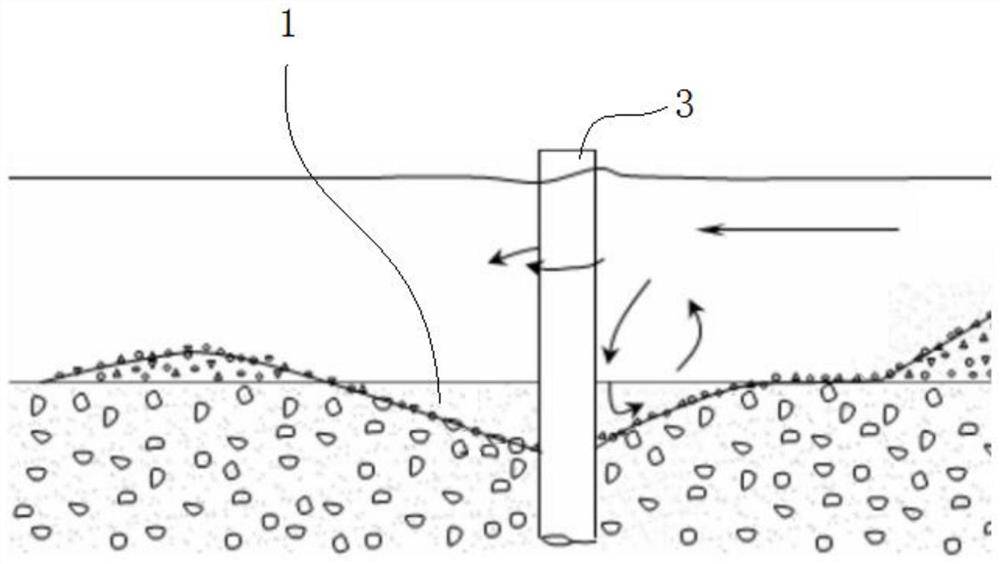

[0042] See figure 1 When the pile foundation is blocked, the pile foundation is surrounded by a complex three-dimensional water flow structure, including the front decline in jet, the pier swirl system and the bridge, resulting in a local flushing pit to form a partial flushing in the pile base 3. . When describing the flushing pit 1 morphology, the pile foundation 3 and the bed sand contact line are recorded as a flush pit depth boundary. The scope of flushing pits on the horizontal surface is recorded as the outer boundary of the pit. The distance between the depth boundary of the flush pit to the riverbed surface 2 is a flushing depth.

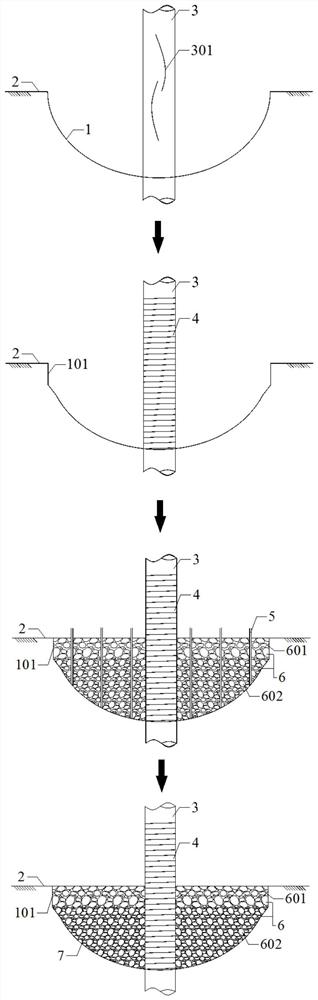

[0043] See image 3 In this embodiment, a reservoir area bridge pile foundation is provided, including the following steps:

[0044] 1) The water in the river in the reservoir area, extracts the water in the flushing pit, and removes loose mud stone in the flushing pit 1.

[0045] 2) Trust the inner wall of the flush pit. The boundary of the r...

Embodiment 2

[0062]This embodiment provides a reservoir area bridge pile foundation brush protection method, including the following steps:

[0063] 1) In the drying period of the river in the reservoir area, the water is pumped in the rumored pit, and the outer contour of the brush pit will be adjacent to the side wall of the riverbed surface 2, and the trim is 0.2 ~ 0.5 times the brush depth, and Clear the loose mud stone in the side of the flush pit and the bottom.

[0064] 2) Deflection, loose, honeycomb, corrosion, etc. to remove concrete, expose the concrete structure layer, and repair the surface with the repair material.

[0065] 3) Formation of the underglast, uniformly coated the primer to the surface of the pile foundation 3 that is about to stick to the FRP material 4, and the surface of the surface fingers refers to drying.

[0066] 4) Formulate the finding glue, the surface depression of the pile foundation is filled with flatness, no angular angular, and the surface finger is fo...

Embodiment 3

[0073] See Figure 4 This example discloses a library zone bridge pile base composite protector using the method described in Example 1, including FRP material 4 and grouting protective layer 6.

[0074] The FRP material 4 is attached to the sidewall of the pile foundation at the constant water level surface.

[0075] The grouting protective layer 6 is filled in the flushing pit 1. The grouting protective layer 6 includes a stone protective layer 602 and a gravel protective layer 601 from top to bottom. The median particle diameter of the stone material in the stone protective layer 602 is not less than 0.3 times the thickness of the stone protective layer 602.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com