Preparation method of high-thermal-conductivity metal-based carbon fiber heating body material

A carbon fiber heating and metal-based technology, applied in the field of metal-based carbon fiber materials, can solve the problems of small heating area, poor interface performance, and low surface energy, and achieve the effects of improving thermal conductivity, reducing thermal expansion coefficient, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] An embodiment of the present invention provides a method for preparing a high thermal conductivity metal-based carbon fiber heating element material, the preparation method comprising:

[0036] Preparation of carbon fiber powder with surface activity by microwave radiation ultrasonic oxidation;

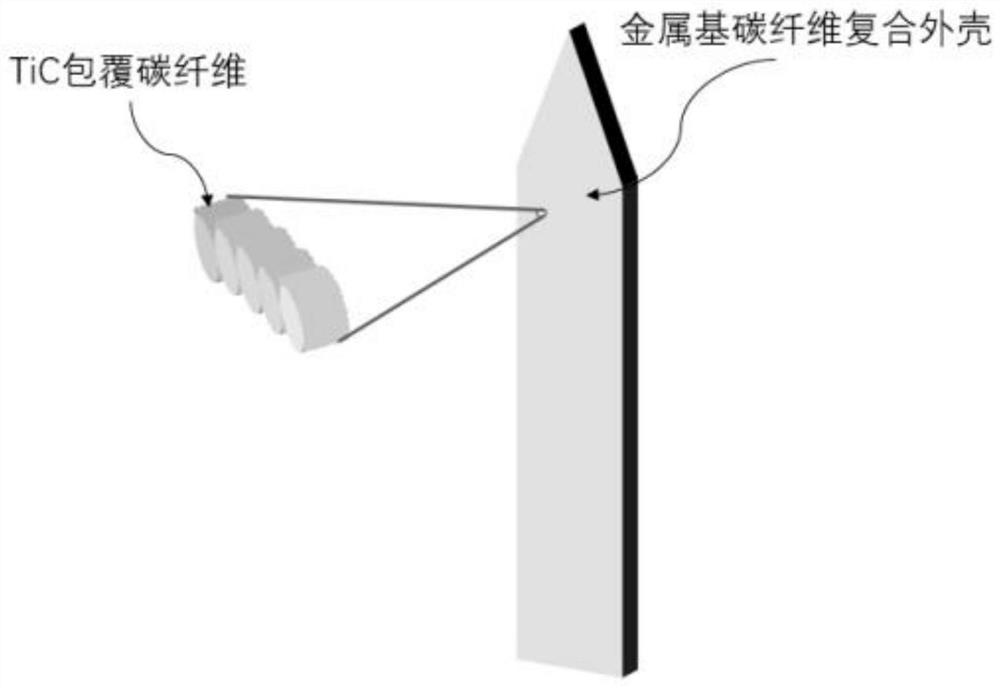

[0037] Coating carbide on the surface of the carbon fiber powder by a molten salt method to prepare a coated carbon fiber powder;

[0038] The coated carbon fiber powder and the alloy powder are pressed into the shape of a heating needle by a hot pressing method to prepare a heating material.

[0039] In one embodiment, the microwave radiation ultrasonic oxidation method is specifically as follows: select carbon fibers to intrude into the oxide solution, completely disperse the carbon fibers in the solution, put the solution into a microwave oven for radiation treatment, and use ultrasonic waves to mix at the same time, and the ultrasonic oxidation is completed Afterwards, the...

Embodiment 1

[0059] (1) Carbon fiber surface treatment

[0060] First, PAN carbon fibers with a diameter of 10 μm and a length of 50 μm were completely immersed in an acetone solution, stirred and degummed for 24 hours, washed repeatedly with deionized water, and then dried in a drying oven at 120°C for 12 hours. Use deionized water to prepare a hydrogen peroxide solution with a mass fraction of 5%, and then take the degummed carbon fiber and completely immerse it in the hydrogen peroxide solution. The amount of the hydrogen peroxide solution is 30 times the mass of the carbon fiber. Mechanical stirring makes the carbon fiber completely dispersed in the solution. Put the solution into microwave heating Radiation treatment was carried out in the furnace for 30 s, and ultrasonic waves were used for mixing at the same time. After the treatment, the samples were taken out, washed with deionized water until neutral, and dried at 120°C to constant weight.

[0061] (2) Preparation of carbon fiber...

Embodiment 2

[0066] (1) Carbon fiber surface treatment

[0067] First, PAN carbon fibers with a diameter of 10 μm and a length of 50 μm were completely immersed in an acetone solution, stirred and degummed for 24 hours, washed repeatedly with deionized water, and then dried in a drying oven at 120°C for 12 hours. Use deionized water to prepare a hydrogen peroxide solution with a mass fraction of 5%, and then take the degummed carbon fiber and completely immerse it in the hydrogen peroxide solution. The amount of the hydrogen peroxide solution is 30 times the mass of the carbon fiber. Mechanical stirring makes the carbon fiber completely dispersed in the solution. Put the solution into microwave heating Radiation treatment was carried out in the furnace for 30 s, and ultrasonic waves were used for mixing at the same time. After the treatment, the samples were taken out, washed with deionized water until neutral, and dried at 120°C to constant weight.

[0068] (2) Preparation of carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com