Steel bar forcible entry device suitable for narrow space

A narrow space, steel bar technology, applied in the direction of grinding drive device, grinding automatic control device, grinding/polishing safety device, etc., can solve the problems of fixing the steel bar in the working area, increasing the disturbance of the steel bar, secondary bleeding, etc. To achieve the effect of avoiding vibration of metal foreign objects, reducing the amount of noise, and reducing the feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]A specific embodiment of the present invention is given below. DETAILED DESCRIPTION OF THE INVENTION The present invention is for further details, and does not limit the scope of the present application.

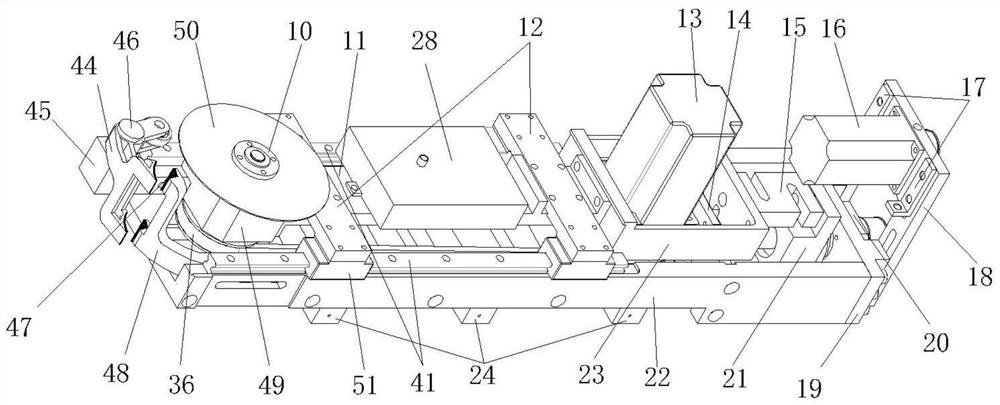

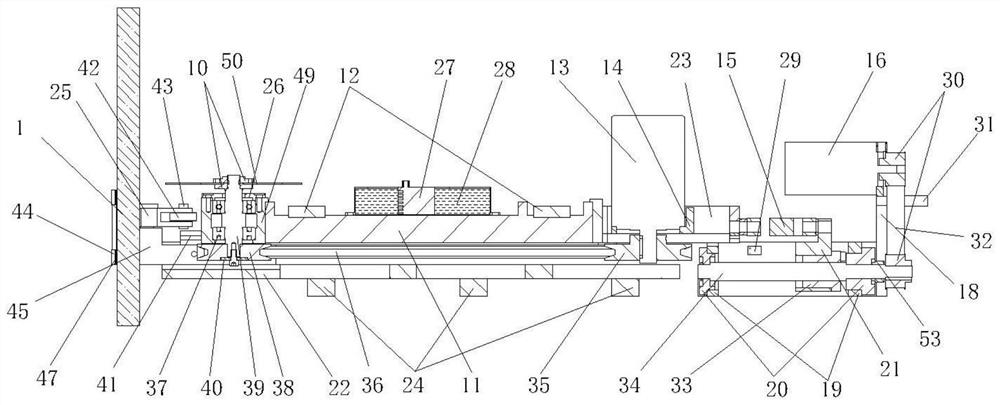

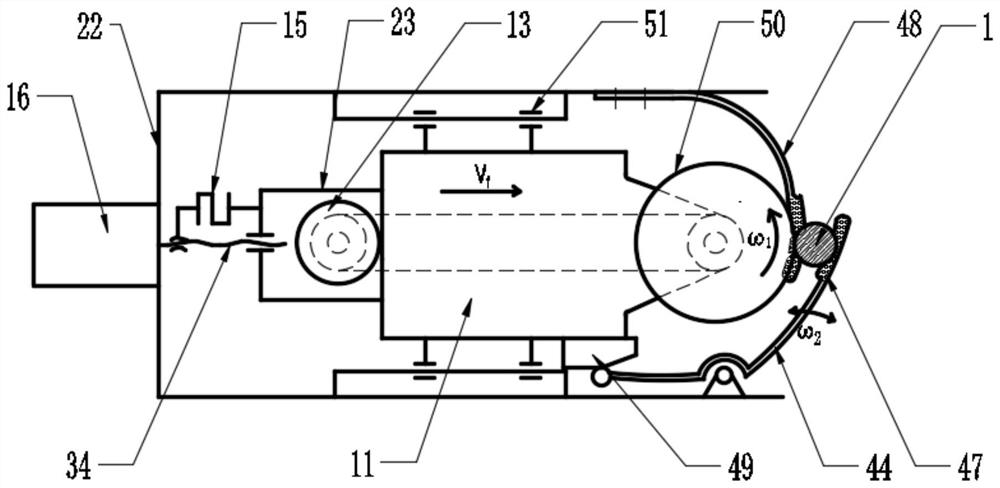

[0038]According to the present invention, a steel bar dismantling device (referred to as a reinforcing device) suitable for a narrow space, wherein the body portion includes a screw pressure plate 10, a main beam 11, a rail connecting plate 12, a servo motor 13, a wheel Tight plate 14, force transmission member 15, stepping motor 16, synchronous pulley tensioning plate 17, stepping motor frame 18, lead screw support seat 19, lead screw support 20, screw nut 21, rack 22, motor Shelf 23, sliding bearing 25, bearing end cover 26, synchronous pulley 30, synchronous belt 32, screw nut 33, screw 34, large pulley 35, triangular belt 36, bearing 37, small pulley 38, spindle 39, Small pulley top 40, rail 41, ball bearing 42, dynamic clamping cable 43, dynamic clamp 44, dynamic clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com