Bolt axial force monitoring system and monitoring method based on visual deep learning

A visual depth and monitoring system technology, applied in the direction of integrated learning, force/torque/work measuring instrument, measuring device, etc., can solve the problems of cost increase, complex project implementation, and reduced necessity of bolt monitoring, etc., to achieve convenient engineering use, Cost reduction, excellent technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

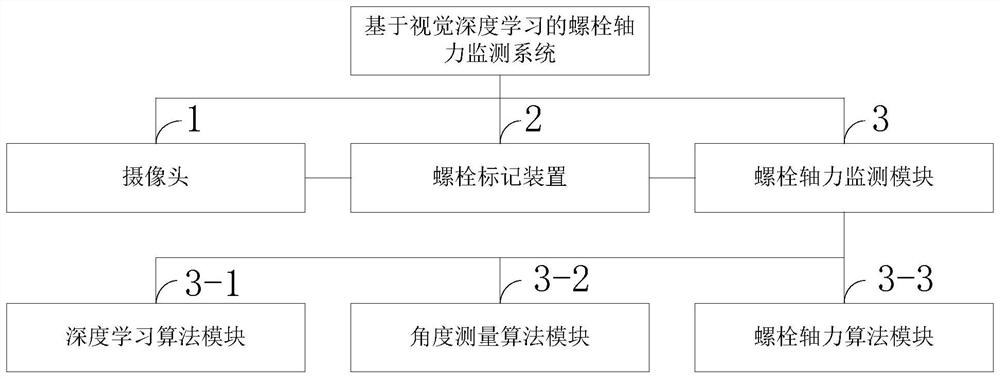

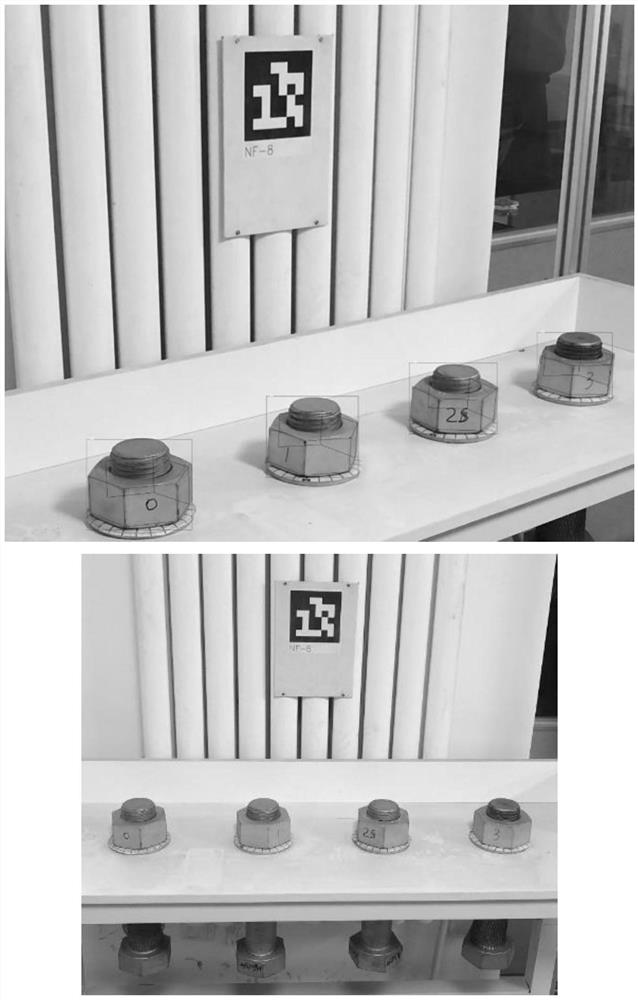

[0062] The bolt axial force monitoring system based on visual deep learning provided by the embodiment of the present invention includes: a camera, a bolt marking device, and a software algorithm part.

[0063] When the bolt is tightened, the nut rotates clockwise under the action of torque, generating axial force in the bolt. Contrary to this process, the bolt axial force attenuation is divided into two parts: the non-rotating bolt axial force attenuation and the rotating bolt axial force attenuation. Among them, the non-rotational axial force attenuation refers to the attenuation of the axial force when the nut does not rotate backwards. This is mainly because the surface of the clamped object is embedded or compressed under the action of the axial force of the bolt. It is caused by the collapse phenomenon, and part of it is caused by the plastic deformation of the screw thread; the non-rotational axial force attenuation generally occurs within 24 hours after the bolt is tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com