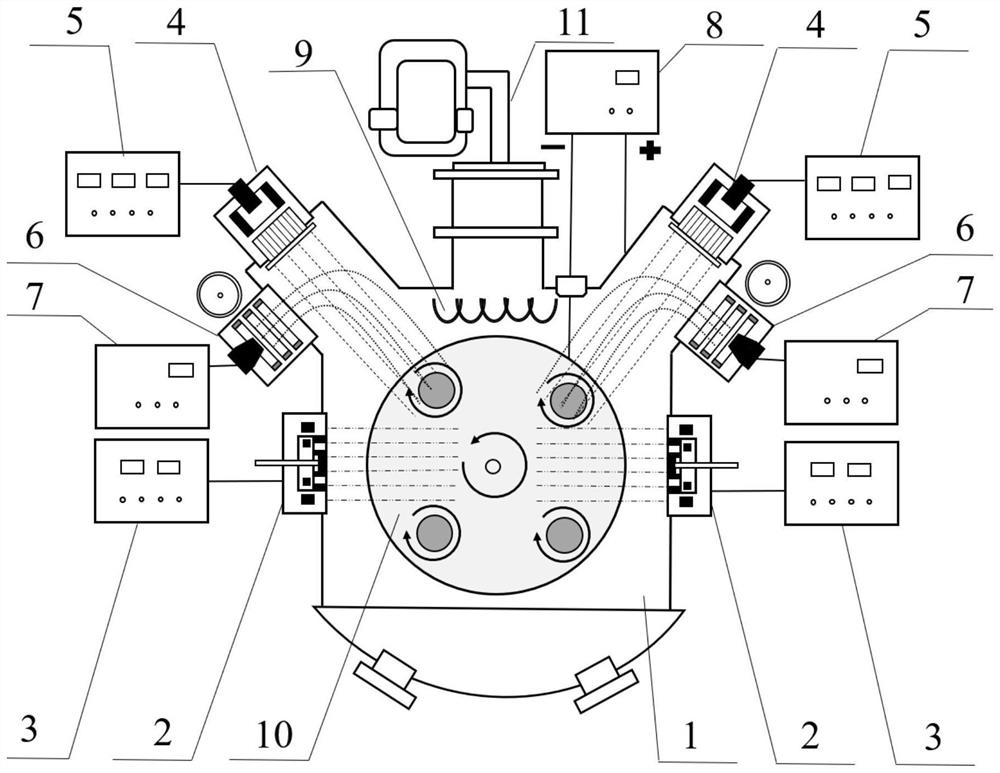

Composite film plating device

A composite coating and thin film technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of low production efficiency, low ionization rate, poor film quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

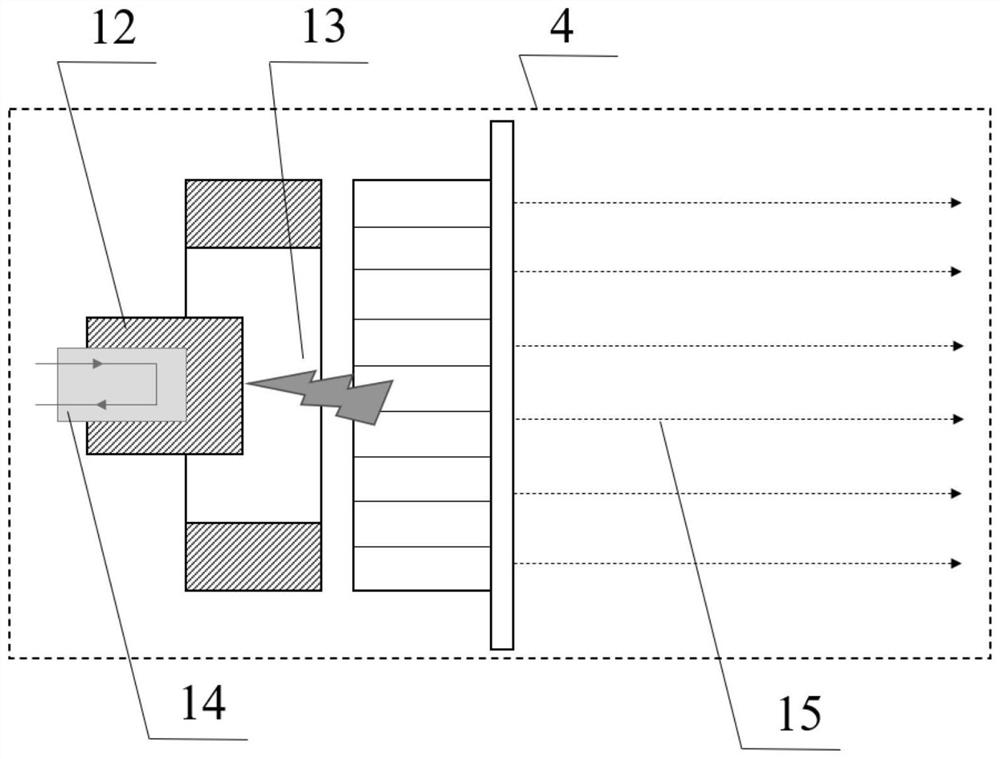

Method used

Image

Examples

example 1

[0063] Example 1 Prepare Ti / Ta-C carbon film thin film by above-mentioned composite coating device

[0064] (1) The target material of the pulse arc ion source is graphite, the target material of the magnetic filter arc ion source is titanium, the gas source of the ion beam source is nitrogen, and the substrate is silicon wafer.

[0065] (2) Cleaning before coating: ultrasonically clean the silicon wafers with acetone, ethanol and deionized water for 10-15 minutes in order to remove pollutants on the surface of the substrate; put the ultrasonically cleaned silicon wafers into a blast drying oven for 30-30 minutes 45min, take it out and set aside.

[0066] (3) Vacuum extraction: Start the composite coating equipment, mount the coating substrate on the workpiece turret, close the vacuum chamber hatch, start the mechanical rotary vane pump for rough vacuuming; when the pressure in the vacuum chamber reaches 5Pa, start the turbomolecular pump Further evacuate the vacuum chamber u...

example 2

[0071] Example 2 Preparation of Cr / Ta-C:Cr composite thin film by above-mentioned composite coating device

[0072] (1) The target material of the pulsed arc ion source is graphite, the target material of the magnetic filter arc ion source is chromium, the gas source of the ion beam source is argon, and the substrate is 304 stainless steel.

[0073] (2) Cleaning before coating: Use gasoline solvent, ethanol and deionized water to ultrasonically clean the coating substrate for 10-15 minutes in order to remove pollutants on the surface of the substrate; put the ultrasonically cleaned stainless steel sheet into a blast drying oven for 30 minutes ~45min, take it out and set aside.

[0074] (3) Vacuum extraction: Start the composite coating equipment, mount the coating substrate on the workpiece turret, close the vacuum chamber hatch, start the mechanical rotary vane pump for rough vacuuming; when the pressure in the vacuum chamber reaches 5Pa, start the turbomolecular pump Furthe...

example 3

[0079] Example 3 Prepare ZrN thin films by the above-mentioned composite coating device

[0080] (1) The target material of the magnetic filter arc ion source is zirconium, the gas source of the ion beam source is argon and nitrogen, and the substrate is TC4 titanium alloy.

[0081] (2) Cleaning before coating: ultrasonically clean the titanium alloy substrate with acetone, ethanol and deionized water for 5-10 minutes in order to remove pollutants on the surface of the substrate; put the substrate after ultrasonic cleaning into a blast drying oven to dry 30min, take it out and set aside.

[0082] (3) Vacuum extraction: Start the composite coating equipment, mount the coating substrate on the workpiece turret, close the vacuum chamber hatch, start the mechanical rotary vane pump for rough vacuuming; when the pressure in the vacuum chamber reaches 5Pa, start the turbomolecular pump Further evacuate the vacuum chamber until the predetermined vacuum degree of 1.5E-3Pa is reached....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com