A kind of filler of MOF loaded corrosion inhibitor, self-repairing anti-corrosion coating and preparation method thereof

A technology of anti-corrosion coatings and corrosion inhibitors, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor dispersion of fillers, small application range, poor anti-corrosion effect, etc., to achieve easy dispersion, improve Anti-corrosion performance, avoiding the effect of sharp attenuation of self-healing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

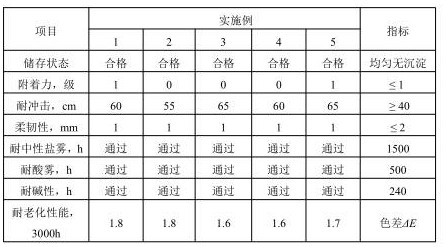

Examples

Embodiment 1

[0025] 1. A preparation method of a metal-organic framework compound-loaded corrosion inhibitor filler

[0026] 1) Add 0.004 mol copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) Dissolve in 100 mL of deionized water, slowly add 10 mL of an aqueous solution containing 0.008 mol of hexamethylenetetramine dropwise under stirring at room temperature, continue stirring for 30 minutes, then add 0.004 mol of terephthalic acid, stir and disperse evenly, Transfer to a polytetrafluoroethylene reactor, seal it and place it in an oven at 150°C for 48 hours to react, stop the reaction, filter the solid in the reactor, and dry the filter cake at 100°C for 12 hours to obtain the metal organic framework compound hmt-MOF.

[0027] 2) At room temperature, disperse 1.0 g hmt-MOF in a mixed solvent of 20 mL deionized water and ethanol (v : v = 1 : 1), add 0.03 g hexamethylenetetramine under stirring conditions, and continue stirring After standing still for 10 hours, filter, wash the filter cak...

Embodiment 2

[0033] 1. A preparation method of a metal-organic framework compound-loaded corrosion inhibitor filler

[0034] 1) Add 0.005 mol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolve in 100 mL of deionized water, slowly add 10 mL of an aqueous solution containing 0.01 mol of hexamethylenetetramine dropwise under stirring at room temperature, continue stirring for 30 minutes, then add 0.0075 mol of terephthalic acid, stir and disperse evenly, Transfer it to a polytetrafluoroethylene reactor, seal it and place it in an oven at 170°C for 56 hours to react, stop the reaction, filter the solid in the reactor, and dry the filter cake at 100°C for 12 hours to obtain the metal organic framework compound hmt-MOF.

[0035] 2) Disperse 1 g hmt-MOF in a mixed solvent of 30 mL deionized water and ethanol (v : v = 1 : 1) at room temperature, add 0.03 g hexamethylenetetramine under stirring conditions, and continue stirring After standing still for 12 hours, filter, wash the filter ca...

Embodiment 3

[0041] 1. A preparation method of a metal-organic framework compound-loaded corrosion inhibitor filler

[0042] 1) Add 0.006 mol nickel chloride hexahydrate (NiCl 2 ·6H 2 O) Dissolve in 100 mL of deionized water, slowly add 10 mL of an aqueous solution containing 0.012 mol of hexamethylenetetramine dropwise under stirring at room temperature, continue stirring for 30 minutes, then add 0.008 mol of terephthalic acid, stir and disperse evenly, Transfer to a polytetrafluoroethylene reactor, seal it and put it in an oven at 170°C for 65 hours to react, stop the reaction, filter the solid in the reactor, and dry the filter cake at 100°C for 12 hours to obtain the metal organic framework compound hmt-MOF.

[0043] 2) Disperse 1 g hmt-MOF in a mixed solvent of 30 mL deionized water and ethanol (v : v = 1 : 1) at room temperature, add 0.07 g 2-methylimidazole under stirring conditions, and continue stirring for 14 h , after standing still for a period of time, filtered, the filter c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com