A kind of polyatomic co-doped graphene, preparation method and application

A graphene and co-doping technology, applied in graphene, chemical instruments and methods, structural parts, etc., can solve problems such as complex processes, and achieve clean preparation process, good stability and cycle performance, and high repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

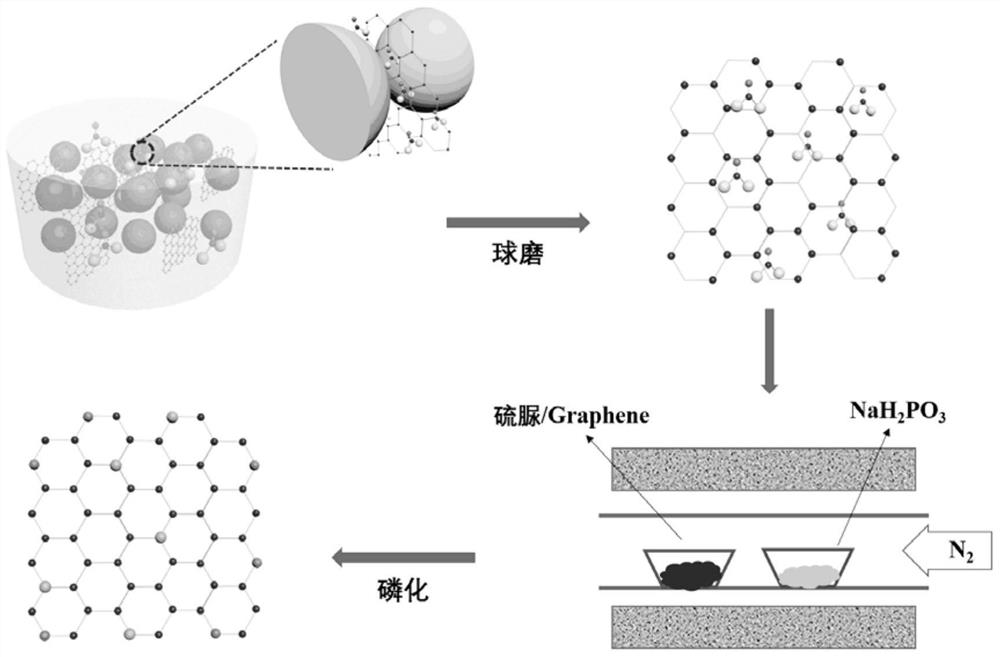

[0035] A preparation method of polyatomic co-doped graphene (NSP-Graphene) with ORR / OER bifunctional catalytic activity (the process is as follows: figure 1 shown), the steps are as follows:

[0036] Step 1: Weigh 4g of thiourea into 5mL of deionized water, stir magnetically until the thiourea is completely dissolved to obtain a thiourea solution;

[0037] Step 2: put 0.05g graphene and the thiourea solution in step 1 into the ball mill jar, select 6 times of the zirconia balls with a diameter of 3 mm compared to the total weight of graphene and thiourea, and install the ball mill jar;

[0038] Step 3: set the ball milling speed (250rpm) and the ball milling time (30min), and carry out ball milling treatment to graphene and thiourea;

[0039]Step 4: freeze-dry the ball-milled mixture obtained in step 3, freeze-drying time 12h, and finally obtain a dry powder sample of graphene and thiourea;

[0040] Step 5: Place the dried powder sample in step 4 and disodium hydrogen phosph...

Embodiment 2

[0042] A preparation method of polyatomic co-doped graphene (NSP-Graphene) with ORR / OER bifunctional catalytic activity (the process is as follows: figure 1 shown), the steps are as follows:

[0043] Step 1: Put 0.05g of graphene and a small amount of deionized water into the ball mill jar, select 6 times the total weight of the graphene and select zirconia balls with a diameter of 3mm, and install the ball mill jar;

[0044] Step 2: set the ball milling speed (250rpm) and the ball milling time (30min), and carry out ball milling treatment to graphene;

[0045] Step 3: freeze-dry the ball-milled mixture obtained in step 2, freeze-drying time 12h, and finally obtain a dry powder sample of graphene;

[0046] Step 4: Place the dried powder sample in step 3 and disodium hydrogen phosphate in an atmosphere furnace, wherein disodium hydrogen phosphate is placed in front of the airflow, and its mass is 8 times that of the powder sample. Under nitrogen, the temperature was increased...

Embodiment 3

[0048] A preparation method of polyatomic co-doped graphene (NSP-Graphene) with ORR / OER bifunctional catalytic activity (the process is as follows: figure 1 shown), the steps are as follows:

[0049] Step 1: Weigh 4 g of thiourea, add it into 5 mL of deionized water, and stir magnetically until the thiourea is completely dissolved to obtain a thiourea solution;

[0050] Step 2: put 0.05g graphene and the thiourea solution in step 1 into the ball mill jar, select 6 times of the zirconia balls with a diameter of 3 mm compared to the total weight of graphene and thiourea, and install the ball mill jar;

[0051] Step 3: set the ball milling speed (250rpm) and the ball milling time (30min), and carry out ball milling treatment to graphene and thiourea;

[0052] Step 4: freeze-dry the ball-milled mixture obtained in step 3, freeze-drying time 12h, and finally obtain a dry powder sample of graphene and thiourea;

[0053] Step 5: Place the dried powder sample of Step 4 in an atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com