Motor train unit sanding pipe joint disconnection fault detection method based on image processing

A technology for image processing and disconnecting faults, applied in the field of image processing, can solve problems such as missed detection and false detection, and achieve the effects of reducing false positives, enhancing edges, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

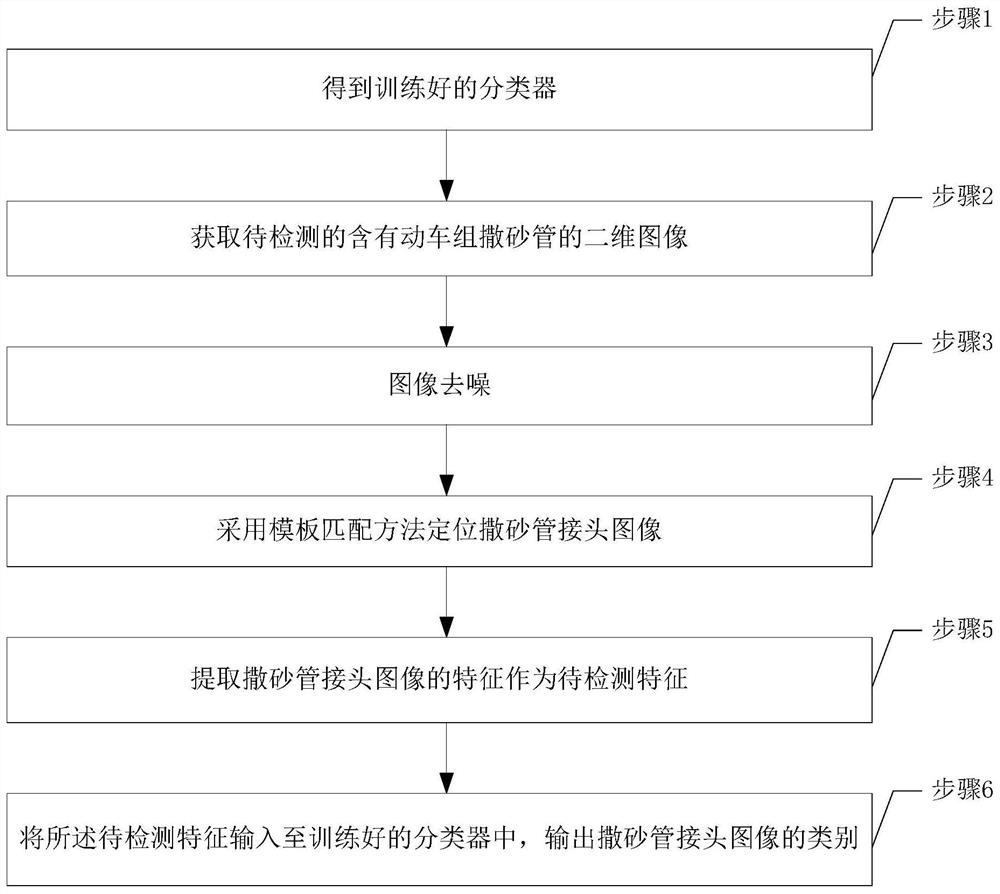

[0051] Specific implementation mode one: combine figure 1 Describe this embodiment, the method for detecting disconnection faults of sand-spraying pipe joints of EMUs based on image processing in this embodiment, the method includes:

[0052] Step 1. Collect the image of the sand-spreading pipe part of the EMU, extract the features of the sand-spraying pipe part image as the training feature, use the training feature to train the support vector machine, and obtain a trained classifier, wherein the trained classifier can use The images of the sanding pipe components are divided into two categories, namely, the disconnected image of the sanding pipe joint and the undisconnected image of the sanding pipe joint;

[0053] Step 2. Obtain the two-dimensional image containing the sand-sprinkling pipe of the EMU to be detected;

[0054] Step 3, denoising the two-dimensional image to obtain a noise-free image containing the sand-sprinkling pipe of the EMU;

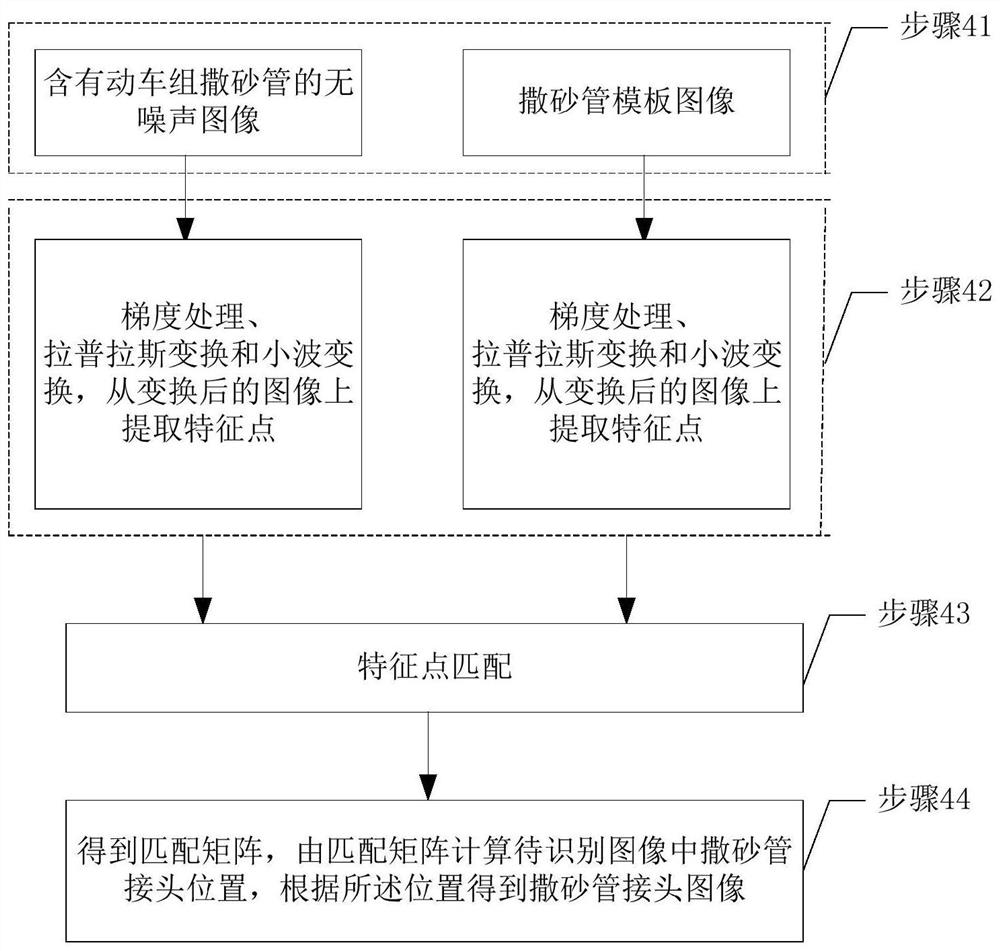

[0055] Step 4, matching th...

specific Embodiment approach 2

[0059] Specific embodiment two: this embodiment is the fault detection method based on the image processing EMU sanding pipe joint disconnection of specific embodiment one, in step 2, obtain the two-dimensional image containing the EMU sanding pipe to be detected, including :

[0060] Use camera equipment to collect images of the bottom of the EMU;

[0061] A two-dimensional image containing the sanding pipe of the EMU is intercepted from the bottom image of the EMU.

[0062] In this embodiment, the line scanning method may be used to collect the bottom image of the EMU to form a two-dimensional image with a wide field of view and high precision. It can effectively reduce the time required for fault identification and improve the accuracy of identification.

specific Embodiment approach 3

[0063] Specific embodiment three: This embodiment is a method for detecting disconnected faults of sand-spraying pipe joints of EMUs based on image processing in Embodiment 1. In step 3, the two-dimensional image is denoised to obtain sand-spraying pipes containing EMUs. Noise-free images of , including:

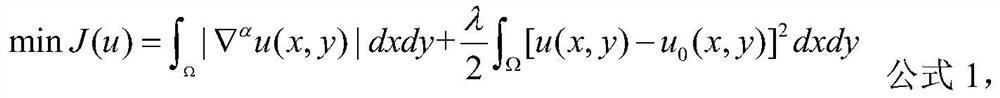

[0064] The denoising model is used to denoise the two-dimensional image, and the denoising model is:

[0065]

[0066] In the formula, J(u) is the objective function of denoising processing, minJ(u) represents the minimum value of J(u), is the regular term of the two-dimensional image containing the EMU sand pipe, for fidelity item, is a fractional gradient operator, (x, y) are the coordinates of each pixel in the two-dimensional image containing the EMU sanding pipe, Ω represents the range of (x, y), u(x, y) is the noise-free image containing the EMU sanding pipe, u 0 (x, y) is a two-dimensional image containing the EMU sand pipe, u 0 (x,y)=u(x,y)+n(x,y)n(x,y) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com