Surface gradient high-entropy alloy layer and preparation method thereof

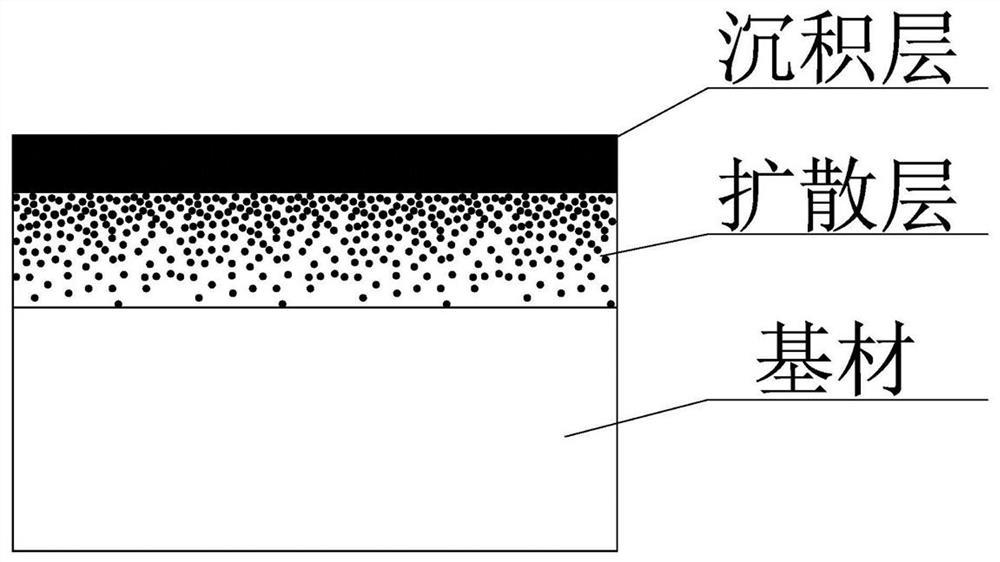

A technology of high-entropy alloy and surface gradient, which is applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve problems such as easy cracks and holes, poor bonding force, and pollute the environment, so as to ensure the bonding strength , The effect of high surface modification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The pre-infiltration base material of this example is a pure iron sample of 180 mm × 15 mm × 4 mm, an auxiliary source barrel of φ150 mm × 200 mm is used, and the source material is tungsten (W) with a specification of φ4 mm × 30 mm. : 26, Molybdenum (Mo): 26, Chromium (Cr): 26, Titanium (Ti): 34, Iron (Fe): 32, Nickel (Ni): 38, 6 types of rod-shaped sources The material is evenly inserted into the small hole of the auxiliary source barrel; the surface of the pre-infiltrated substrate is first polished smooth with a manual polishing machine, then soaked in dilute hydrochloric acid with a mass fraction of 15% for 30 minutes, and then cleaned with an ultrasonic cleaner and acetone 10 minutes, then dry with a hair dryer; use such as figure 1 For the dual-cathode plasma solid-state metallurgical equipment shown, the auxiliary source barrel inserted with the rod-shaped source material is placed on the work plate connected to the source pulse power supply, and three self-made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com