Metal inner surface modification device and method

A technology of inner surface and metal, which is applied in the field of plasma surface modification, can solve the problems of axial uneven implantation dose, uneven plasma density, uneven implantation dose, etc., and achieve the effect of high surface modification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

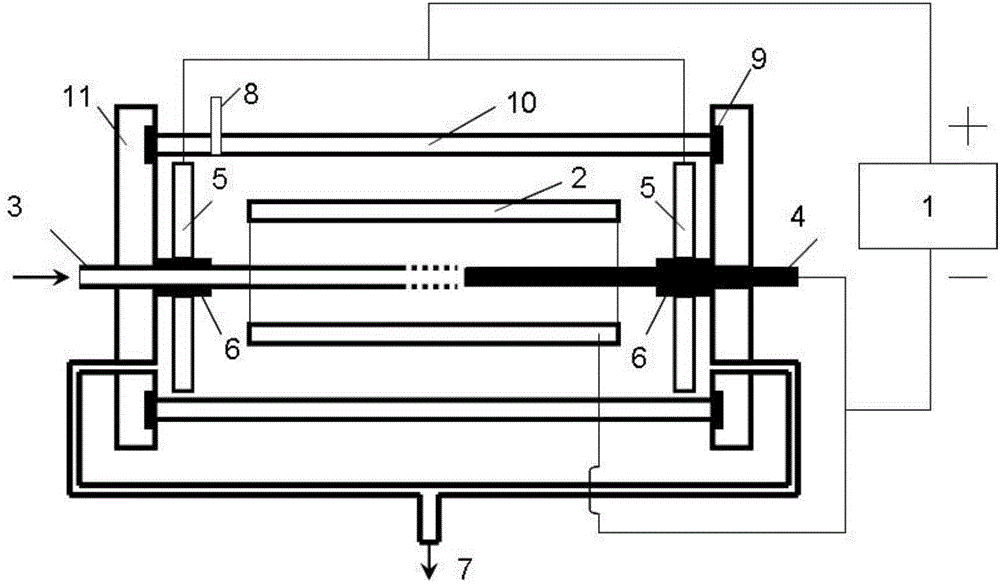

[0016] Such as figure 1 As shown, adjust the cathode distance to 5mm, the cathode and anode distance to 20mm, and vacuum to 10 -3 Torr, argon gas was introduced to 0.05 Torr, a DC pulse voltage of 2 kV was added, and the sample was cleaned with plasma for 10 min. Introduce 40% nitrogen, adjust the pressure of the vacuum chamber to 3Torr, add a DC pulse power supply, maintain the discharge current at 0.3A, the substrate temperature is about 500°C, and the reaction time is 2h.

Embodiment 2

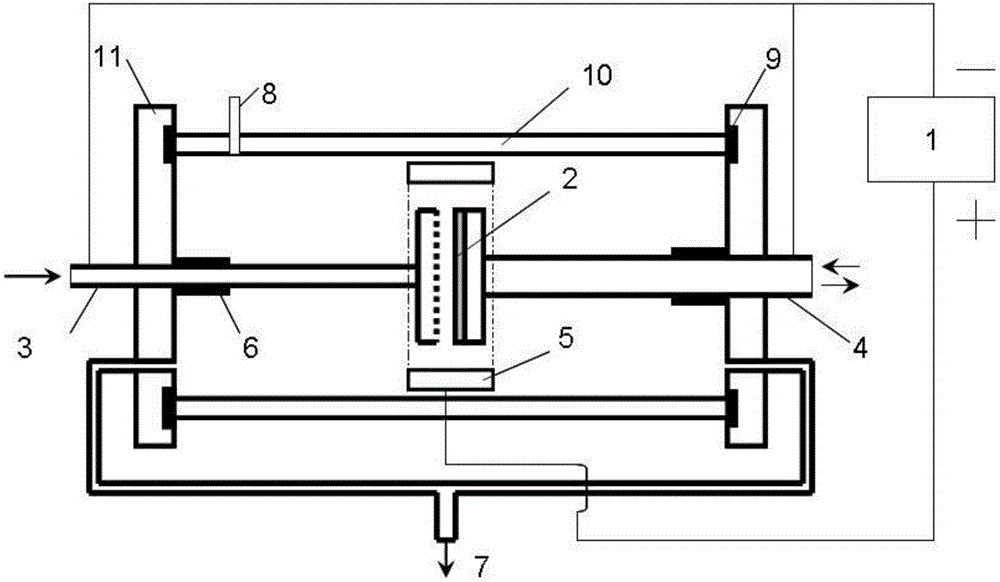

[0018] Such as figure 2 As shown, adjust the cathode distance to 10mm, the cathode and anode distance to 40mm, and vacuum to 10 -3 Torr, pass argon gas to 0.05 Torr, pass water to cool the substrate holder, and the substrate temperature does not exceed 300°C. A DC pulse voltage of 2 kV was added, and the sample was cleaned with plasma for 10 min. Introduce 20% acetylene gas, adjust the pressure of the vacuum chamber to 0.5 Torr, add a DC pulse power supply, maintain the discharge current at 0.2A, and the reaction time is 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com