Rust removal device for steel in building construction

A technology for building construction and steel, which is applied to grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of disorderly placement of steel, low coverage, and reduced construction efficiency, so as to maintain work efficiency. , Avoid being blocked, reduce the effect of manual and physical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

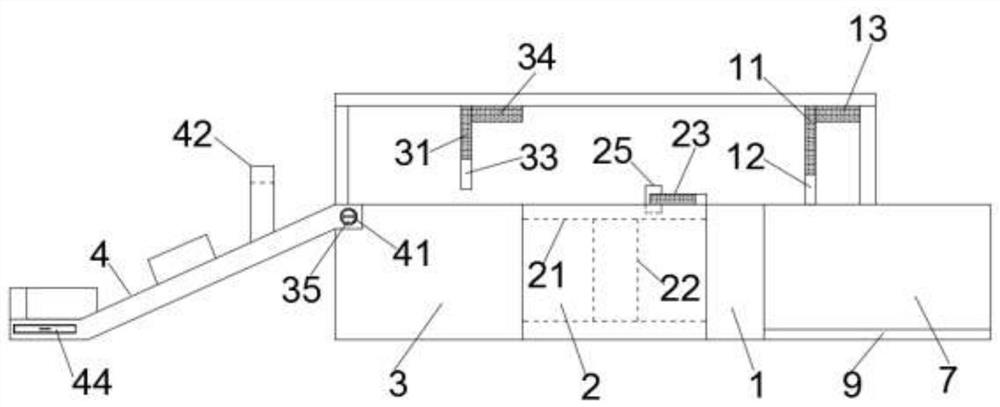

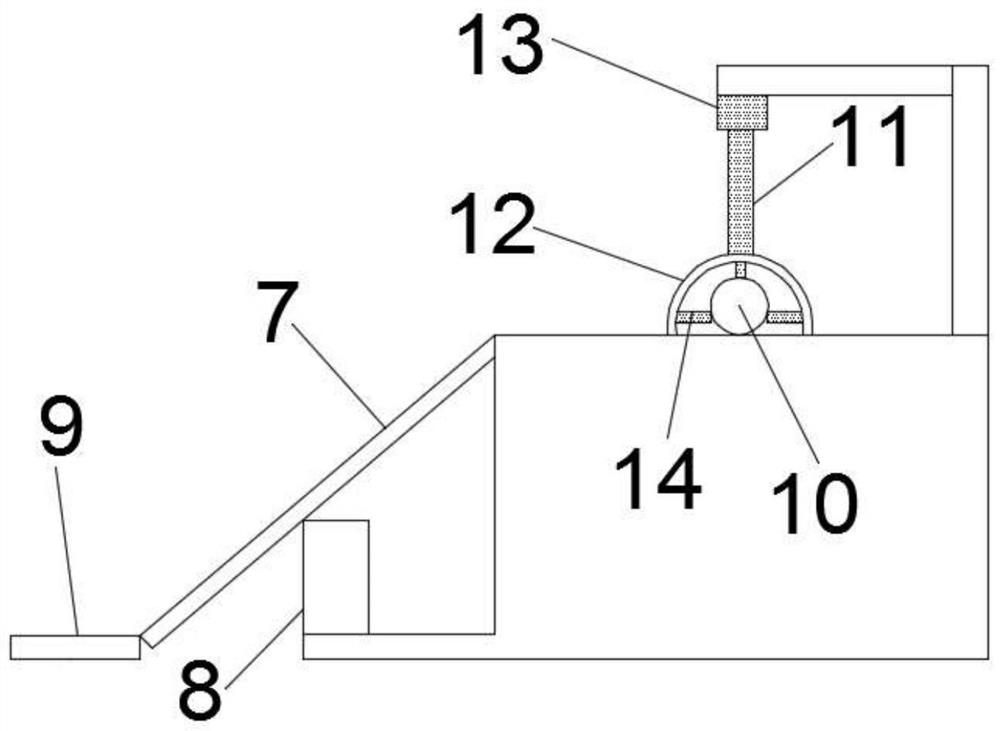

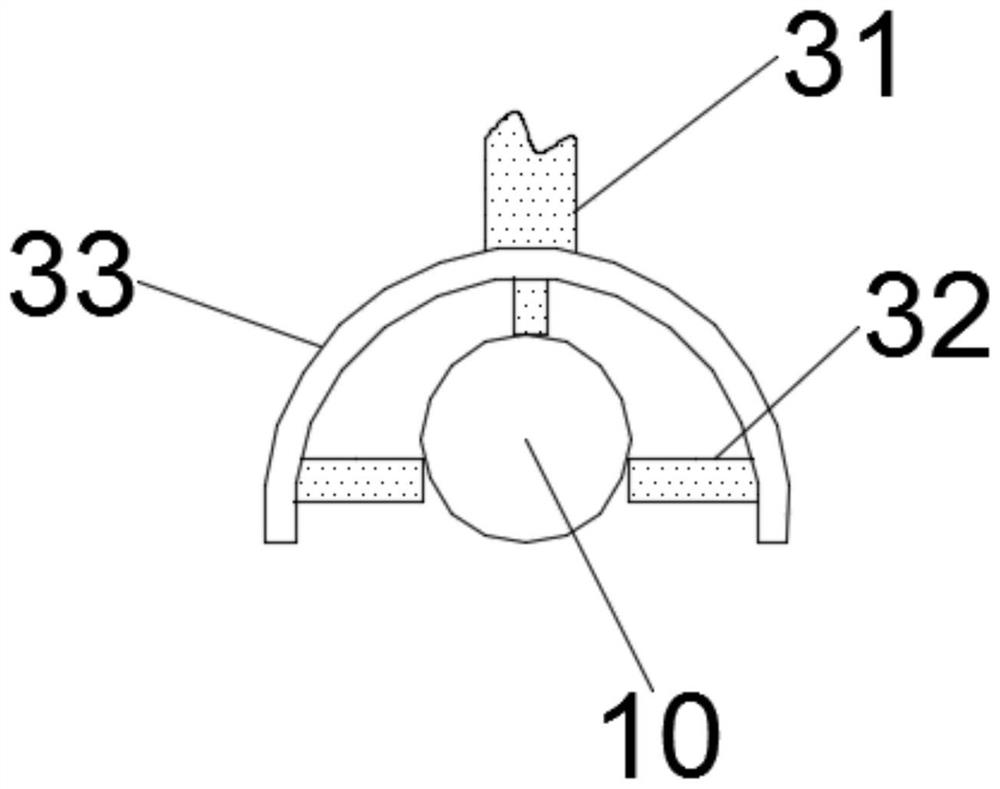

[0032] see Figure 1 to Figure 4, the present invention provides a technical solution: a rust removal device for steel in building construction, including a support platform, the support platform includes a front conveying platform 1, a middle grinding platform 2 and a rear conveying platform 3, and the front conveying platform 1 includes No. 1 main Electric telescopic rod 11, front positioning ring 12 and No. 2 electric telescopic rod 13, the top of front positioning ring 12 is fixedly connected with the bottom end of No. 1 main electric telescopic rod 11, and the inner side of front positioning ring 12 is fixedly connected with 3 symmetrical No. 1 auxiliary electric telescopic rod 14, No. 2 electric telescopic rod 13 are fixedly connected with the top of No. 1 main electric telescopic rod 11, and the middle grinding table 2 includes movable table 21, No. 1 hydraulic cylinder 22, No. 3 main electric telescopic rod 23, No. 3 auxiliary electric telescopic rod 24 and semicircle ...

Embodiment 2

[0037] see Figure 1 to Figure 5 , the present invention provides a technical solution: a rust removal device for steel in building construction, including a support platform, the support platform includes a front conveying platform 1, a middle grinding platform 2 and a rear conveying platform 3, and the front conveying platform 1 includes No. 1 main Electric telescopic rod 11, front positioning ring 12 and No. 2 electric telescopic rod 13, the top of front positioning ring 12 is fixedly connected with the bottom end of No. 1 main electric telescopic rod 11, and the inner side of front positioning ring 12 is fixedly connected with 3 symmetrical No. 1 auxiliary electric telescopic rod 14, No. 2 electric telescopic rod 13 are fixedly connected with the top of No. 1 main electric telescopic rod 11, and the middle grinding table 2 includes movable table 21, No. 1 hydraulic cylinder 22, No. 3 main electric telescopic rod 23, No. 3 auxiliary electric telescopic rod 24 and semicircle...

Embodiment 3

[0042] see Figure 1 to Figure 6 , the present invention provides a technical solution: a rust removal device for steel in building construction, including a support platform, the support platform includes a front conveying platform 1, a middle grinding platform 2 and a rear conveying platform 3, and the front conveying platform 1 includes No. 1 main Electric telescopic rod 11, front positioning ring 12 and No. 2 electric telescopic rod 13, the top of front positioning ring 12 is fixedly connected with the bottom end of No. 1 main electric telescopic rod 11, and the inner side of front positioning ring 12 is fixedly connected with 3 symmetrical No. 1 auxiliary electric telescopic rod 14, No. 2 electric telescopic rod 13 are fixedly connected with the top of No. 1 main electric telescopic rod 11, and the middle grinding table 2 includes movable table 21, No. 1 hydraulic cylinder 22, No. 3 main electric telescopic rod 23, No. 3 auxiliary electric telescopic rod 24 and semicircle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com