Refrigeration structure

A refrigeration sheet and cold surface technology, which is applied in refrigerators, refrigeration and liquefaction, radiotherapy, etc., can solve the problems of inconvenient assembly, poor heat dissipation efficiency of refrigeration sheets, complex structure, etc., to reduce assembly costs, solve poor assembly, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the various embodiments in the invention and the features in the embodiments can be combined with each other. The invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0039] Assembly: Insert a single copper / aluminum tube into the corresponding hole on the hot side cover of the cooling plate, and wait for the next step of processing

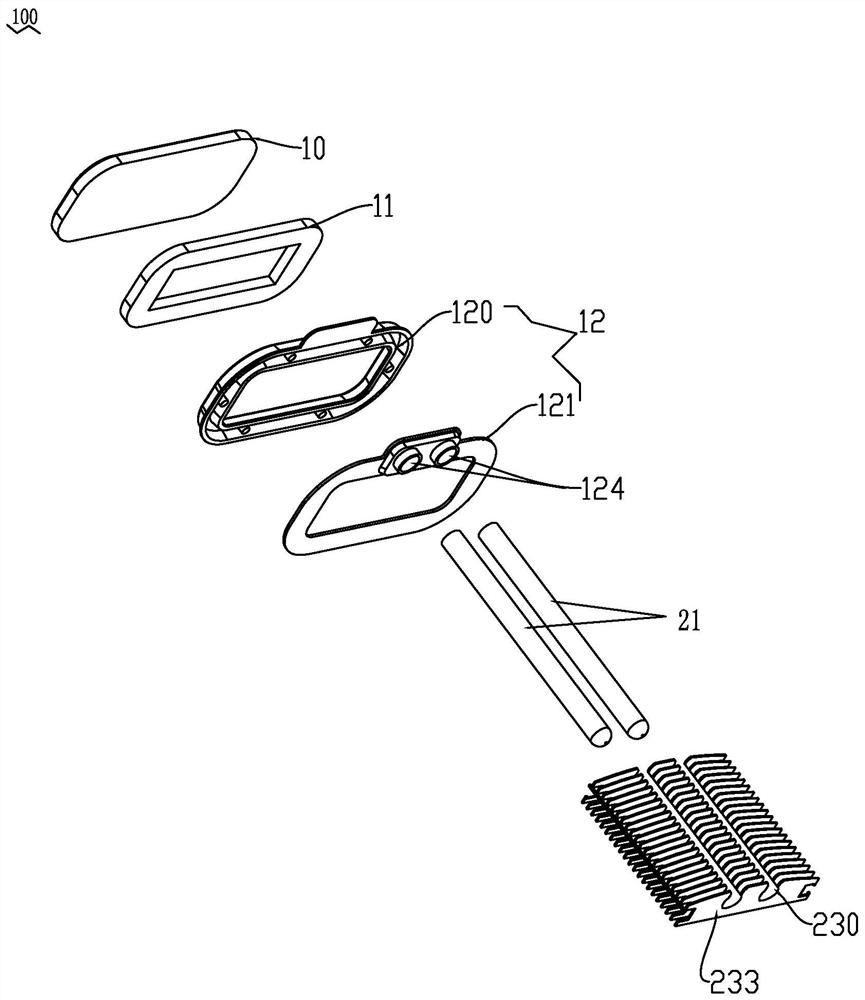

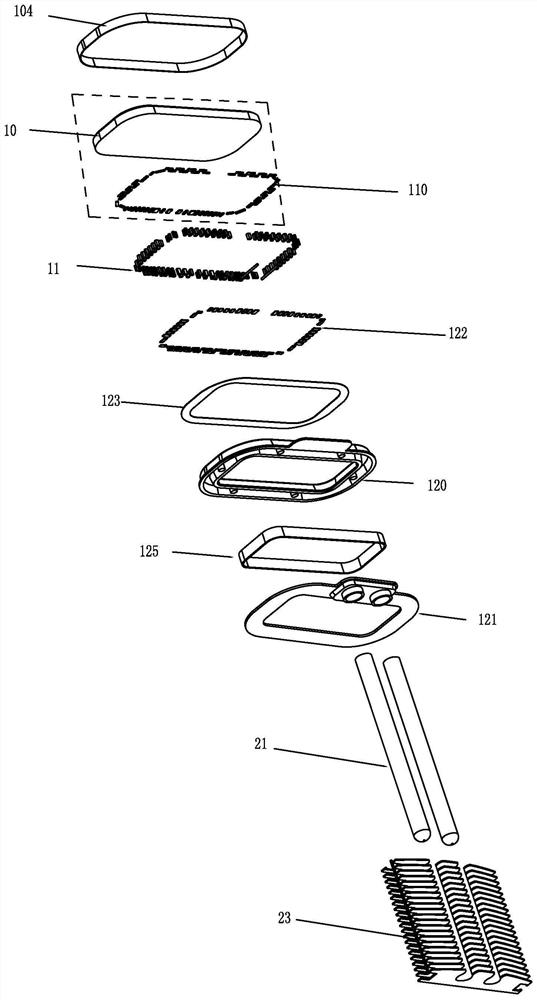

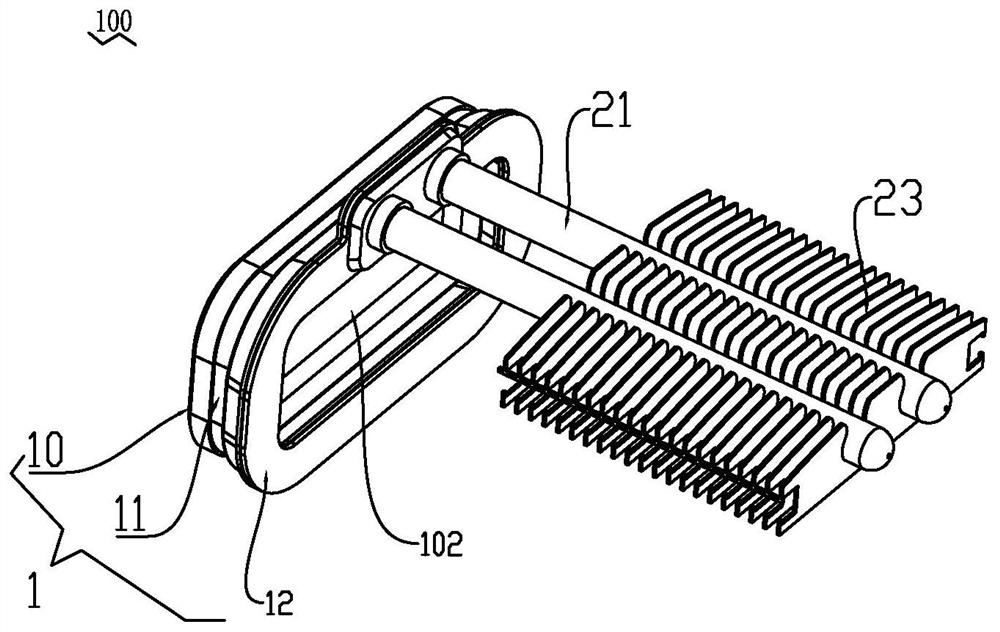

[0040] 1(a)-5, the invention relates to a refrigeration structure 100, preferably a semiconductor cooling system, including a semiconductor cooling chip 1, a heat pipe 21 and a radiator 23, and the heat pipe 21 is connected to the semiconductor cooling chip 1 and Radiator 23 forms a kind of integral structure that semiconductor refrigeration sheet carries radiator. In other embodiments, the radiator 23 can also be directly combined with the peltier 1 to form an integral structure.

[0041] The semiconductor cooling chip 1 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com