High manganese steel metallographic corrosive solution, and preparation method and corrosion method thereof

A configuration method and high-manganese steel technology, applied in the field of steel production, can solve the problems of not being able to truly display all grain boundaries, poor stability of aqua regia corrosive solution, unsuitable for high-manganese steel samples, etc., and achieve good and stable corrosion effect. Good reproducibility and reproducibility, easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

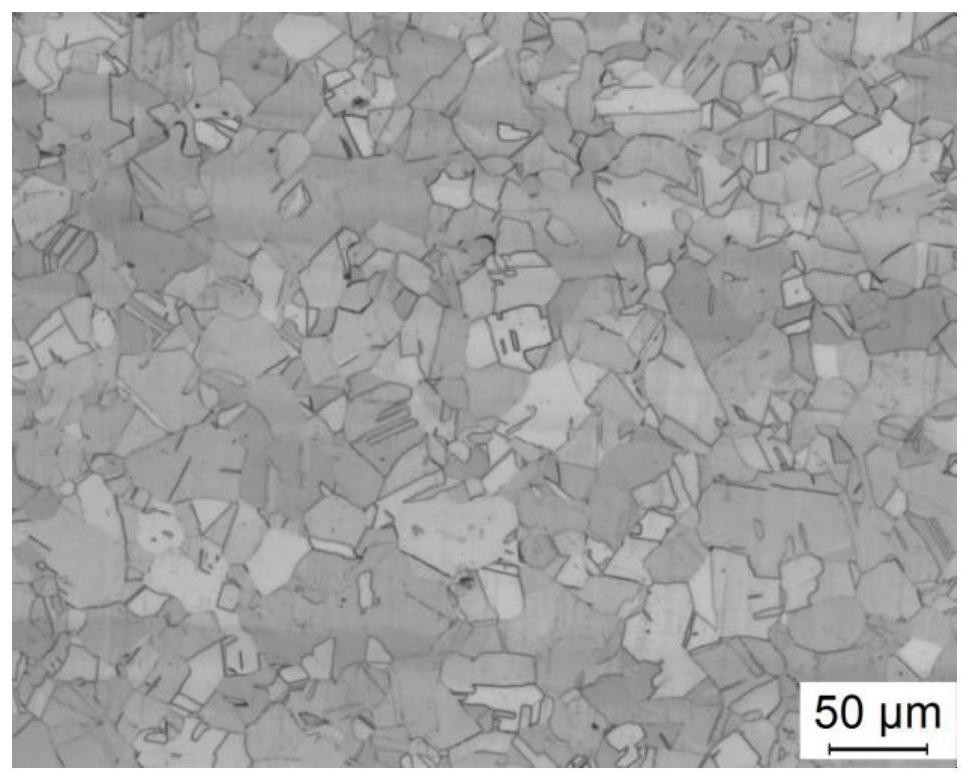

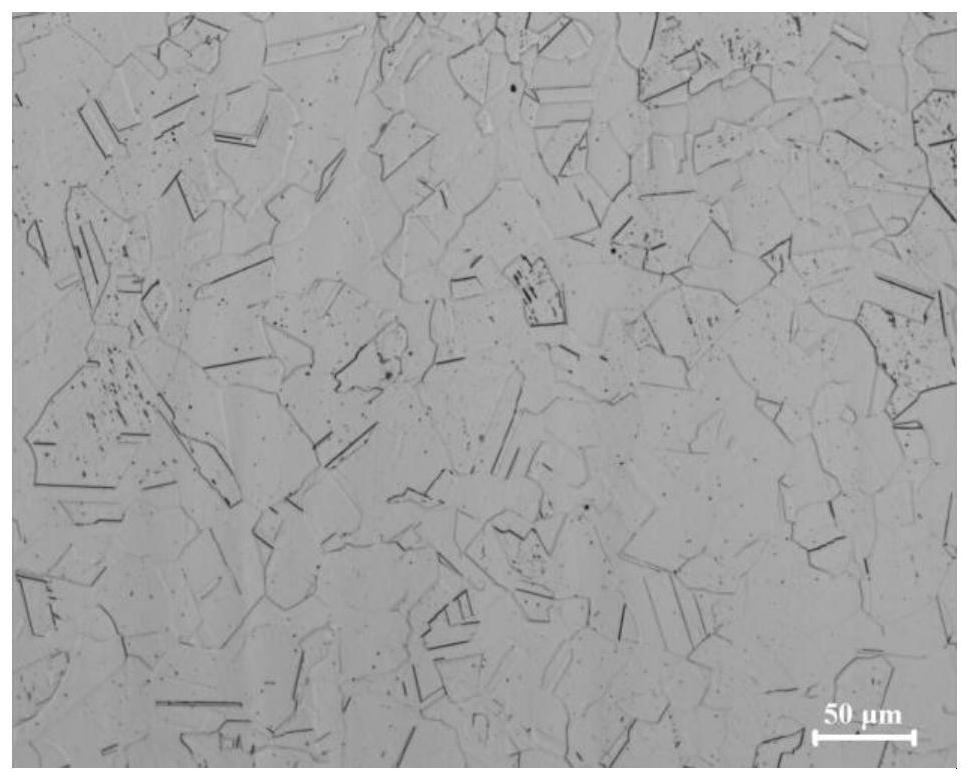

Image

Examples

Embodiment Construction

[0018] A metallographic corrosion solution for high manganese steel provided in this embodiment and its configuration method and corrosion method are as follows:

[0019] (1) Use a balance to weigh out an appropriate amount of CrO 3 solid, add it to a beaker filled with water, stir evenly, and configure it as 10% CrO 3 aqueous solution;

[0020] (2) Slowly add dilute hydrochloric acid, dilute hydrochloric acid and CrO into the beaker 3 The volume ratio of the aqueous solution is 1:2, stir evenly with a glass rod while adding;

[0021] (3) Pour the prepared solution into the reagent bottle and keep it for later use;

[0022] (4) Grind the test surface of the high manganese steel sample with 23% manganese content with 180#, 400#, 600#, 800#, 1000#, 1200# water sandpaper, polish it into a scratch-free mirror surface, and then rinse it with clean water , spray with absolute ethanol, and dry with a hair dryer;

[0023] (5) Hold the polished sample with tweezers and immerse it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com