Low-temperature denitration catalyst and preparation method and application thereof

A low-temperature denitration and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of narrow activity temperature window, increased operating cost, and high reaction temperature, and achieve a wide reaction temperature window. , The effect of simple equipment and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

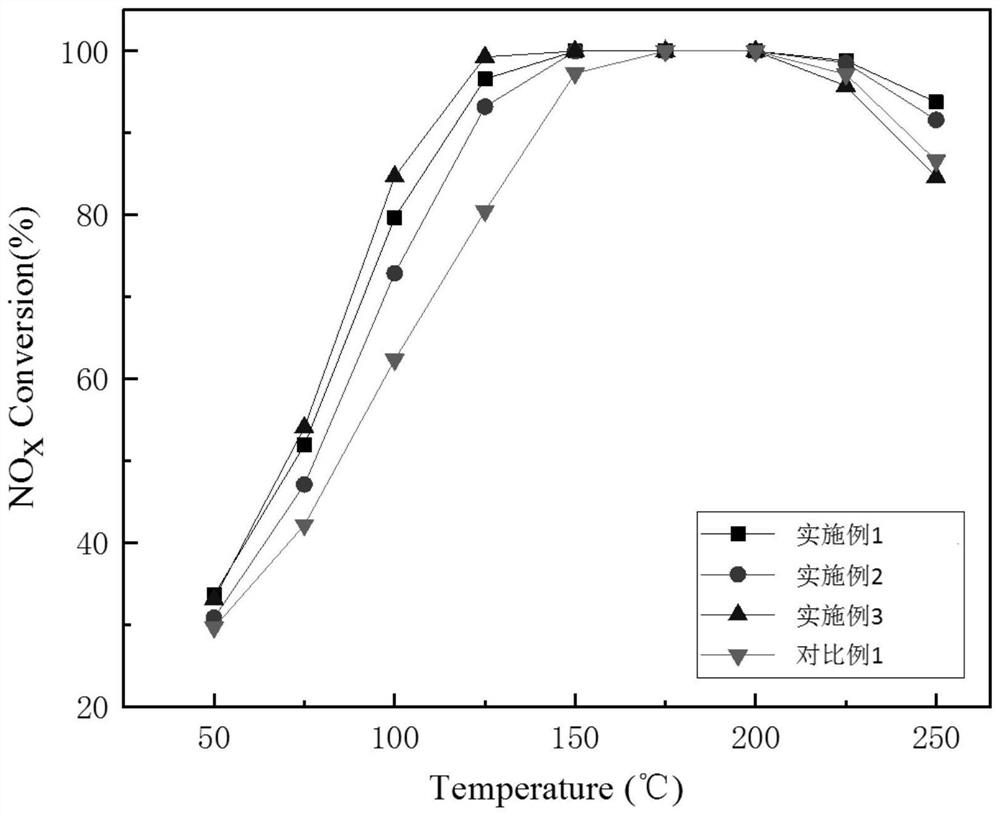

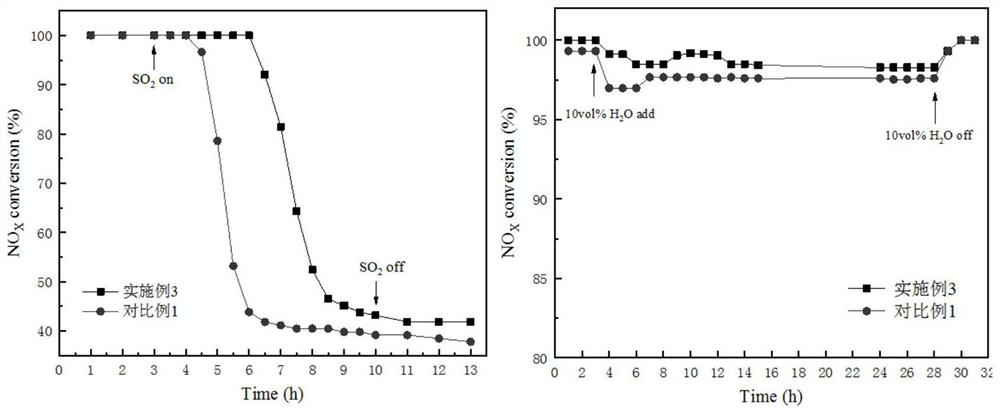

[0033] A Mn-Ce-O x / TiO 2 The preparation method of catalyst, wherein the mol ratio between Mn, Ce and Ti is 0.4:0.1:1, the preparation method of this catalyst comprises the following steps:

[0034] (1) manganese nitrate, cerium nitrate and fuel (content is 100% of the stoichiometric ratio) are dissolved in an appropriate amount of deionized water;

[0035] (2) Add 100nm anatase-type titanium dioxide to the obtained mixed solution, and stir with magnetic force for 1 h;

[0036] (3) Place the product obtained in step (2) in a muffle furnace preheated to 300°C and burn rapidly for 1-2 minutes, then continue to heat up from 300°C to 450°C, roast at 450°C for 4 hours, and finally grind Prepared Mn-Ce-O x / TiO 2 catalyst.

[0037] The resulting Mn-Ce-O x / TiO 2 Catalyst preparation method for NH 3 -SCR reaction, wherein the process conditions of the reaction include:

[0038] (1) The catalytic reaction temperature is 50-250°C;

[0039] (2)N 2 As the balance gas, the con...

Embodiment 1

[0043] A Mn-Ce-O x / TiO 2 The preparation method of catalyst, its specific operation steps are as follows:

[0044] (1) Dissolve 2.87g of manganese nitrate (50% aqueous solution), 1.09g of cerium nitrate and 3.56g of citric acid into 7mL of deionized water, stir and mix evenly;

[0045] (2) Weigh 2g of anatase titanium dioxide with a particle size of 100nm and add it to the mixed solution, and stir it with a magnetic force for 1h;

[0046] (3) Place the product obtained in step (2) in a muffle furnace preheated to 300°C and burn rapidly for 1-2 minutes, then continue to heat up from the combustion temperature of 300°C to 450°C, roast at 450°C for 4 hours, and finally Grinding to produce Mn-Ce-O x / TiO 2 Catalyst, recorded as MCT-100CA.

Embodiment 2

[0048] A Mn-Ce-O x / TiO 2 The preparation method of catalyst, its specific operation steps are as follows:

[0049] (1) Weigh 2.87g of manganese nitrate (50% aqueous solution), 1.09g of cerium nitrate and 3.04g of urea and dissolve them in 7mL of deionized water, stir and mix evenly;

[0050] (2) Weigh 2g of anatase titanium dioxide with a particle size of 100nm and add it to the mixed solution, and stir it with a magnetic force for 1h;

[0051] (3) Place the product obtained in step (2) in a muffle furnace preheated to 300°C and burn rapidly for 1-2 minutes, then continue to heat up from the combustion temperature of 300°C to 450°C, roast at 450°C for 4 hours, and finally Grinding to produce Mn-Ce-O x / TiO 2 Catalyst, recorded as MCT-100U.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com