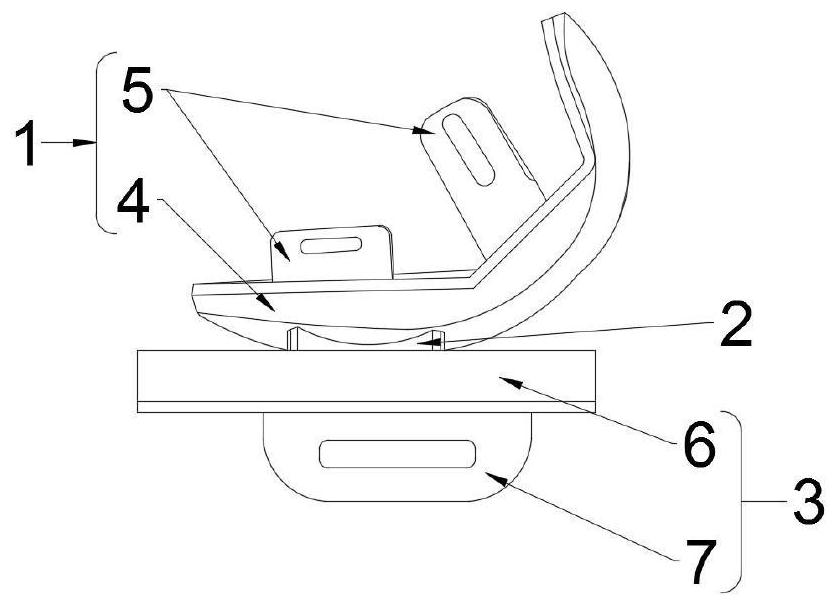

Unicompartmental knee joint prosthesis and manufacturing method thereof

A knee joint prosthesis and manufacturing method technology, applied in knee joints, prostheses, elbow joints, etc., can solve the problems of low friction coefficient, poor initial stability, affecting fatigue performance, etc., and achieve increased specific surface area and friction coefficient. , Improve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] S1. Additive manufacturing of femoral condyle: using cobalt-chromium-molybdenum alloy as raw material and laser three-dimensional forming technology to print, the shape of the No. 1 porous structure is cubic structure, the thickness is 2mm, the porosity is 60%, the wire diameter is 350μm, and the pore size is 500μm femoral condyle;

[0056] S2. HIP treatment of femoral condyle: heat treatment of the femoral condyle obtained in S1, the pressure is kept at 120MPa, the pressure is maintained for 3h, and the HIP temperature is kept at 1170℃;

[0057] S3. Machining the femoral condyle: processing the heat-treated femoral condyle to the designed size;

[0058] S4. Additive manufacturing of tibial plateau: Ti-6Al-17Nb is used as raw material to print the tibial plateau to obtain No. 1 porous structure with a cubic structure, a thickness of 1.5 mm, a porosity of 60%, a wire diameter of 350 μm, and a pore diameter of 350 μm. 500μm femoral condyle;

[0059] S5. HIP treatment of...

Embodiment 2

[0068] S1. Additive manufacturing of femoral condyle: using cobalt-chromium-molybdenum alloy as raw material and selective laser sintering technology to print, the shape of the porous structure No. 1 is a rhombic dodecahedron structure, the thickness is 1mm, the porosity is 50%, and the wire diameter is 200μm, the pore size is 400μm femoral condyle;

[0069] S2. HIP treatment of femoral condyle: heat treatment of the femoral condyle obtained in S1, the pressure is kept at 120MPa, the pressure is maintained for 2h, and the HIP temperature is kept at 1150°C;

[0070] S3. Machining the femoral condyle: processing the heat-treated femoral condyle to the designed size;

[0071] S4. Additive manufacturing of tibial plateau: Ti-13Nb-13Zr is used as raw material to print the tibial plateau, and the shape of the porous structure No. 1 is a rhombic dodecahedron structure, the thickness is 1mm, the porosity is 50%, and the wire diameter is 200μm , with a pore size of 400 μm femoral cond...

Embodiment 3

[0081] S1. Additive manufacturing of femoral condyle: using cobalt-chromium-molybdenum alloy as raw material and electron beam melting technology to print, the shape of the No. 1 porous structure is a truncated octahedron structure, the thickness is 3mm, the porosity is 70%, and the wire diameter is 500μm , with a pore size of 600 μm femoral condyle;

[0082] S2. HIP treatment of femoral condyle: heat treatment of the femoral condyle obtained in S1, the pressure is kept at 120MPa, the pressure is maintained for 4h, and the HIP temperature is kept at 1200°C;

[0083] S3. Machining the femoral condyle: processing the heat-treated femoral condyle to the designed size;

[0084] S4. Additive manufacturing of the tibial plateau: using Ti-5Zr-3Mo-15Nb as the raw material to print the tibial plateau, the shape of the porous structure No. 1 is trabecular bone structure, the thickness is 2mm, the porosity is 70%, and the wire diameter is 500μm, the pore size is 600μm femoral condyle; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com