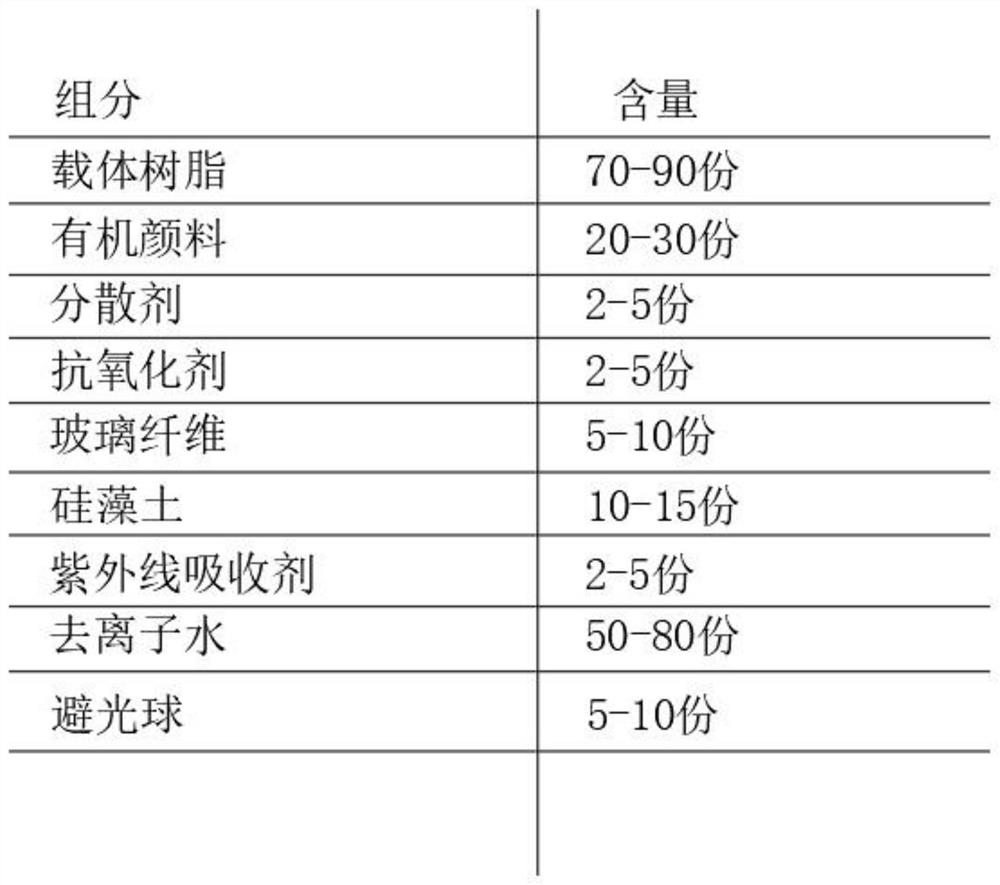

Anti-aging special color master batch formula

A color masterbatch, anti-aging technology, applied in the field of color masterbatch, can solve the problems of large particle size distribution, low service life, poor color masterbatch, etc., to prolong the time of brittleness and strength reduction, Improve the service life and improve the effect of coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] see figure 1 , an anti-aging special color masterbatch formula, including the following ingredients in parts by mass: 70 parts of carrier resin, 20 parts of organic pigment, 2 parts of dispersant, 2 parts of antioxidant, 5 parts of glass fiber, 10 parts of diatomite , 2 parts of UV absorber, 50 parts of deionized water and 5 parts of dark ball.

Embodiment 2

[0048] see figure 1 , an anti-aging special color masterbatch formula, including the following ingredients in parts by mass: 90 parts of carrier resin, 30 parts of organic pigment, 5 parts of dispersant, 5 parts of antioxidant, 10 parts of glass fiber, and 15 parts of diatomite , 5 parts of ultraviolet absorber, 80 parts of deionized water and 10 parts of light-proof ball.

Embodiment 3

[0050] see figure 1 , an anti-aging special color masterbatch formula, including the following ingredients in parts by mass: 80 parts of carrier resin, 25 parts of organic pigment, 4 parts of dispersant, 3 parts of antioxidant, 7 parts of glass fiber, 12 parts of diatomaceous earth , 4 parts of ultraviolet absorber, 70 parts of deionized water and 8 parts of dark ball.

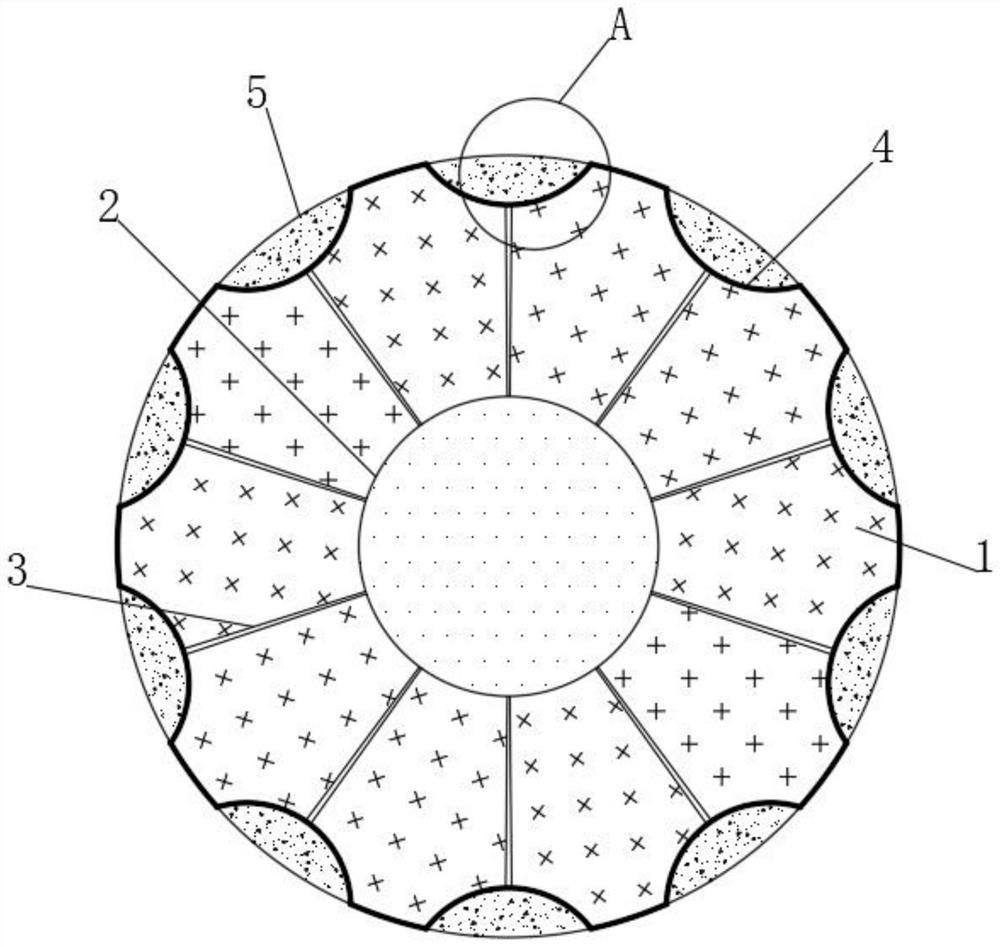

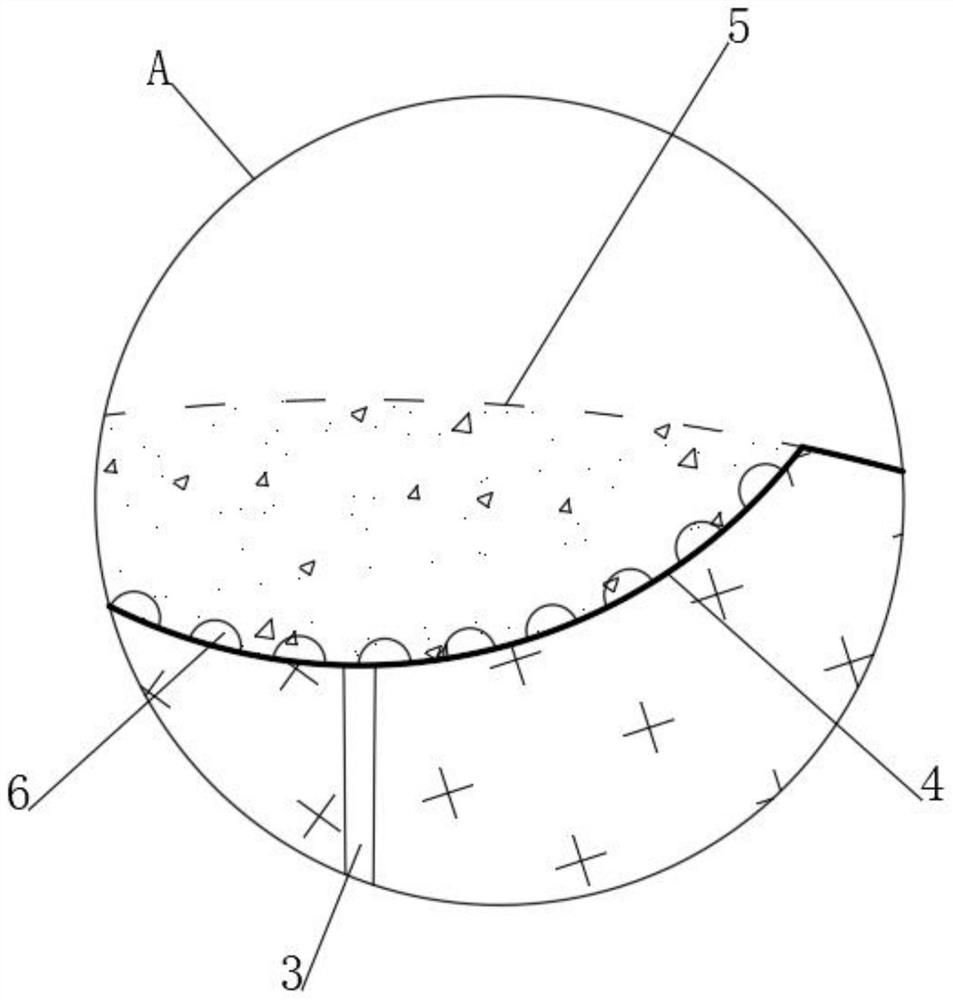

[0051] see figure 2 The light-shielding ball includes a self-expanding sphere 1, an inner air cavity 2 is dug in the middle of the self-expanding sphere 1, a plurality of evenly distributed light-shielding grooves are dug in the outer end of the self-expanding sphere 1, and a plurality of light-shielding grooves are dug inside the self-expanding sphere 1. The air expansion channel 3 corresponding to the light avoidance groove, the air expansion channel 3 communicates with the inner air cavity 2, the arc surface shrapnel 4 is arranged in the light avoidance groove, the limit layer 5 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com