Light emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of difficulty in forming a patterned mask on the side of the light-emitting diode, pattern transfer that cannot be masked, etc. The effect of dissipating heat and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

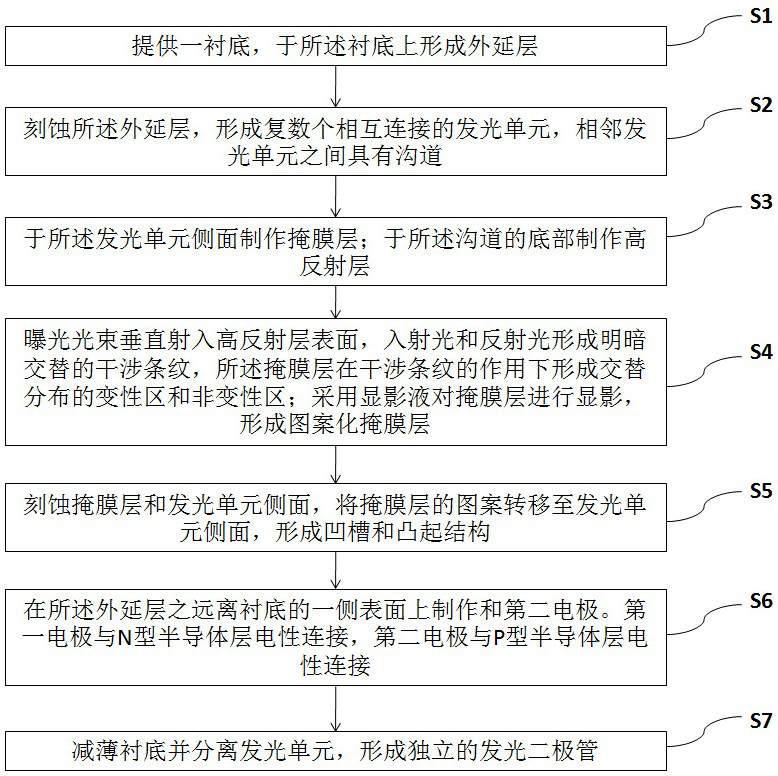

[0042] attached figure 1 It is a flow chart of the light-emitting diode manufacturing method in Embodiment 1 of the present invention. See attached figure 1 , the present invention provides a light-emitting diode manufacturing method using the interference fringes of the exposure beam to expose the side of the light-emitting diode to form grooves and raised structures, which includes:

[0043] S1, see attached figure 2 , a substrate 10 is provided, and an epitaxial layer 20 is formed on the substrate 10 .

[0044]Wherein, the material of the substrate 10 is selected from Al2O3, SiC, GaAs, GaN, AlN, GaP, Si, ZnO, MnO and any combination thereof. The epitaxial growth substrate 10 of this embodiment is illustrated by taking a sapphire substrate 10 (sapphire substrate) as an example, and the lattice direction is (0001), for example, but the present invention does not limit the material and lattice direction of the substrate 10 used. The substrate 10 can be patterned to change...

Embodiment 2

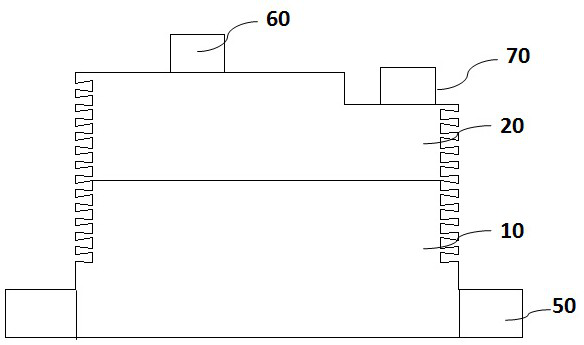

[0068] attached Figure 8 A schematic diagram of the structure of the light emitting diode of the present invention is shown. The light-emitting diode disclosed in the present invention is manufactured by the method of the above-mentioned embodiment 1. The details are as follows: a light-emitting diode, including a substrate 10 and an epitaxial layer 20 stacked on the substrate 10, the side of the epitaxial layer 20 has a groove 82 and a protrusion 81 structure, and the width of the bottom of the groove 82 is greater than the width of the opening .

[0069] The structure of grooves 82 and protrusions 81 on the side of the epitaxial layer 20, on the one hand, changes the path of light incident on the side of the light-emitting diode, which is more conducive to light output, and on the other hand, increases the contact area between the epitaxial layer 20 and the surrounding medium , is conducive to heat dissipation.

[0070] See attached Figure 9 , in this embodiment, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com