Pyrrhotite beneficiation method with high alkalinity floating first and then magnetic separation

A mineral processing method, pyrrhotite technology, applied in the fields of chemical industry and metallurgy, can solve the problems of low price, low iron recovery rate, difficult sales, etc., achieve good economic benefits, reduce production costs, and shorten the effect of mineral processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

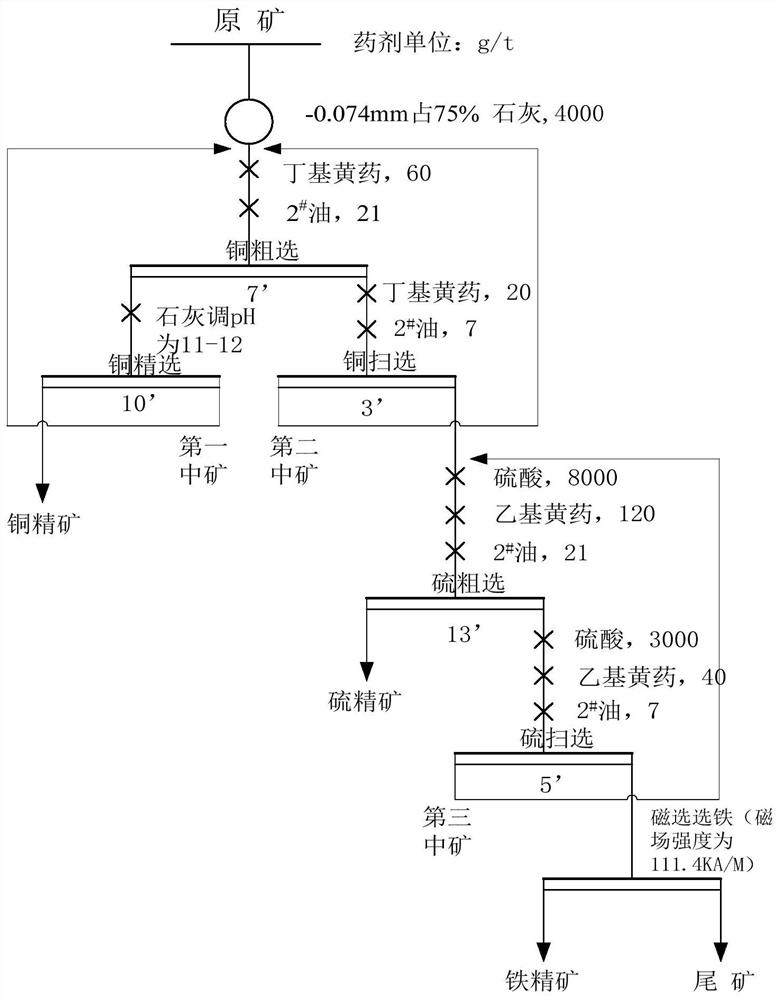

Method used

Image

Examples

Embodiment

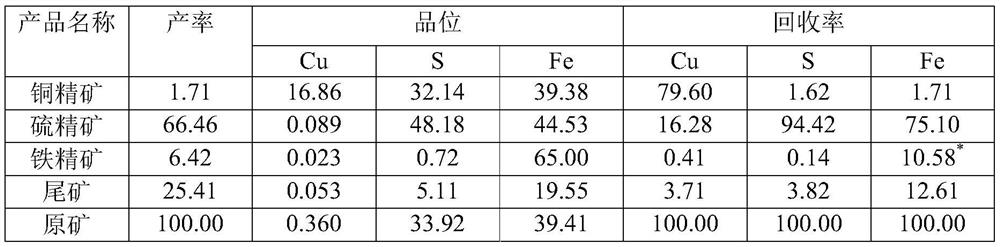

[0039] The present invention will be further illustrated below through a specific embodiment. In this example, the raw material is a certain copper-sulfur iron in Anhui, wherein the raw ore contains Cu0.360%, S33.92%, Fe39.41%. The mineral composition of the ore is complex, among which the metal minerals include chalcopyrite, magnetite, hematite, pyrrhotite, pyrite, galena and siderite. Non-metallic minerals are mainly carbonate minerals. The ore is dominated by massive structure and disseminated structure. Mineral embedding is more complex, magnetite cracks are developed and divided into many particles by calcite, and the embedding particle size is mainly fine particles. Copper minerals are rare and scattered. Pyrite has porphyritic metamorphic, unequal grain metamorphic structure, and the intercalated grain size is extremely unequal grain intercalated. The main reason is that the particle size of the embedding is fine, and it is pierced and cut by the calcite network vei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com