Catalyst with hydrogenation and dimerization functions as well as preparation method and application of catalyst

A technology of catalysts and hydrogenation reactors, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

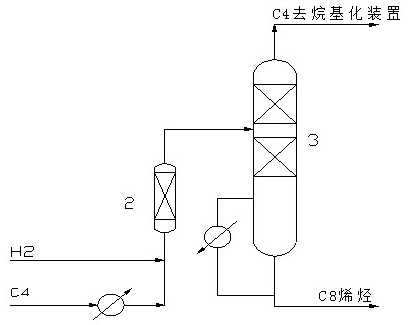

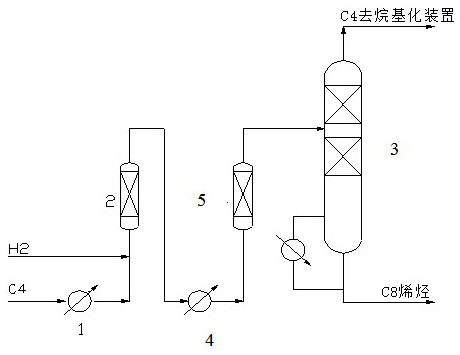

Method used

Image

Examples

Embodiment 1

[0064] 1. Preparation of Inorganic Support

[0065] Mix high-purity aluminum hydroxide dry glue with pseudo-boehmite powder at 1:1, add 5% scallop powder and mix evenly, add 2% citric acid aqueous solution, 10% white carbon black, knead and extrude to make a diameter of 1.5 mm strips were calcined according to the following temperature program to obtain the carrier.

[0066] a drying at room temperature for 24 hours;

[0067] b Dry at 150°C for 4 hours;

[0068] c 3 hours from 150 to 600 ℃;

[0069] d constant temperature for 2 hours;

[0070] e 4 hours from 600 to 1000 ℃;

[0071] f constant temperature for 4 hours;

[0072] g natural cooling;

[0073] The prepared carrier has the following properties:

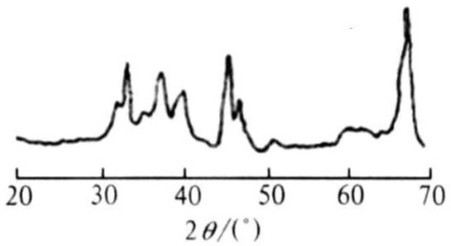

[0074] Crystal phase: δ phase as the main phase; specific pore volume: 0.3-0.5ml / g; specific surface: 100-150m 2 / g, the pore radius is 5.0-20nm.

[0075] 2. Catalyst preparation

[0076] Weigh palladium chloride powder with a content of 59.5% according to the Pd cont...

Embodiment 10

[0080] 1. Preparation of Organic Vehicles

[0081] Use C6-C14 paraffin solvents and aromatic hydrocarbons as porogens, and the amount added is 30% of the weight of the carrier. Styrene and divinylbenzene are made into macroporous pellets by suspension polymerization. In the presence of halogenated alkanes, 102% foam Sulfonated with nicotinic acid, washed with pure water until neutral, and dried to form an organic carrier. Styrene accounted for 0.8 parts by weight, divinylbenzene accounted for 0.2 parts by weight, C6-C14 paraffins accounted for 0.2 parts by weight, aromatics accounted for 0.1 parts by weight, dichloroethane 0.5 parts, fuming sulfuric acid 5 parts, screening diameter 0.35-1.3mm small spheres and vacuum-dried to obtain an organic vehicle. The cross-linking degree of the organic carrier resin is 18%, the particle size is 0.4-1.3%, and the specific surface area is 45m 2 / g, the pore radius is 16-24μm, the specific pore volume is 0.33ml / g, and the exchange capacit...

Embodiment 15

[0087] 1. Preparation of Inorganic Support

[0088] High-purity alumina, add 4% sage powder and mix evenly, add aqueous solution containing 2.5% citric acid and 20% white carbon black, knead and extrude into strips with a diameter of 1.5mm, and roast according to the following temperature procedures to obtain carrier.

[0089] a drying at room temperature for 22 hours;

[0090] b Dry at 120°C for 5 hours;

[0091] c 3 hours from 150 to 550 ° C;

[0092] d constant temperature for 2 hours;

[0093] e rise from 550 to 980°C in 4 hours;

[0094] f constant temperature for 4 hours;

[0095] g natural cooling;

[0096] The prepared carrier has the following properties:

[0097] Crystal phase: δ phase as the main phase; specific pore volume: 0.2-0.5ml / g; specific surface area: 50-120m 2 / g, the pore radius is 5.0-20nm.

[0098] 2. Catalyst preparation

[0099] Weigh palladium chloride powder with a content of 59.5% according to the Pd content requirements of the catalyst, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com