Preparation system and application of pesticide suspending agent for preventing and treating kaffir lily leaf spot

The technology of Clivia leaf spot and suspending agent is applied in the field of pesticides, which can solve the problems of poor control effect, severe drug resistance, short drug action time, etc., and achieve the effects of less environmental pollution, good control effect, and clean and green response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

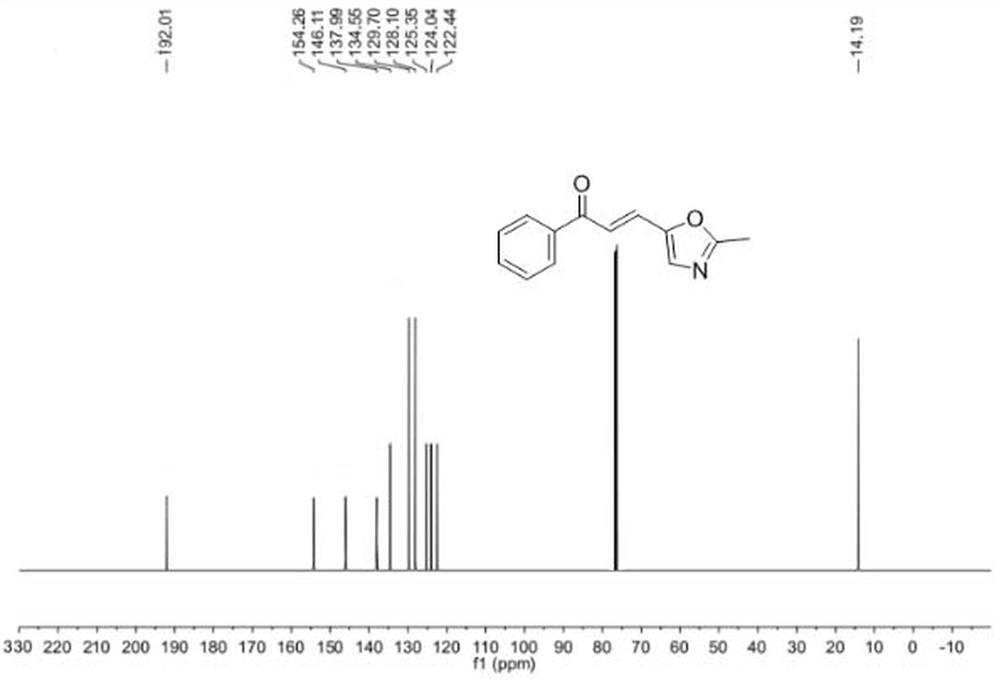

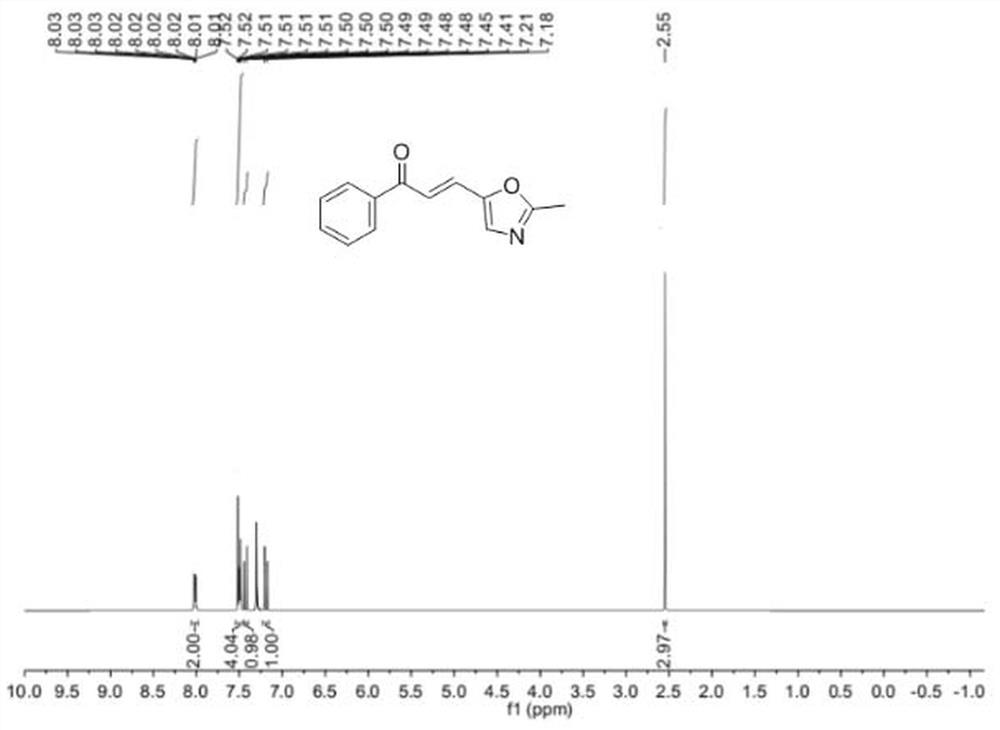

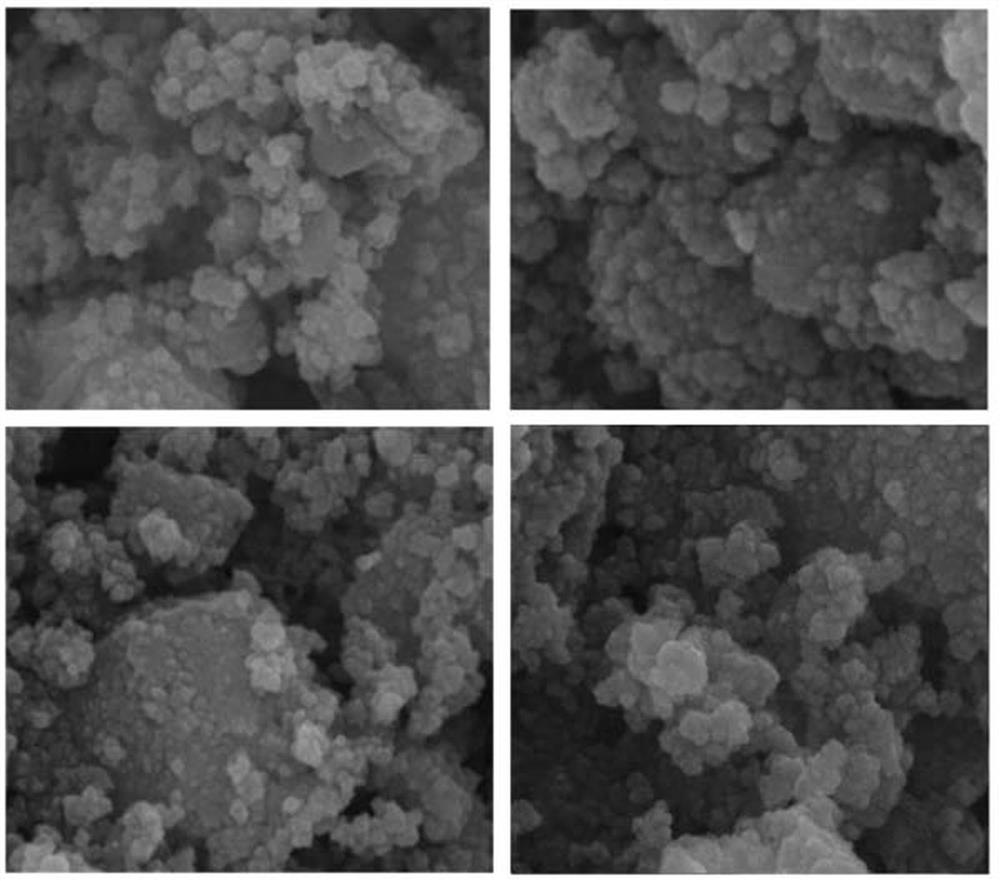

[0036] 1. Catalyst Fe 3 o 4 Preparation of MNPs@Serine-Cu

[0037] (1) Preparation of Fe using conventional coprecipitation technique 3 o 4 MNPs10g, then Fe 3 o 4 MNPs were added to deionized water, ultrasonically dispersed at 30 kHz for 30 min, then 15 g of serine was added, stirred at 50 °C at a speed of 800 rpm for 6 h, cooled to room temperature, and the newly formed Fe was collected by magnetic analysis 3 o 4 MNPs@Serine, washed with deionized water, and dried in vacuum at 80 °C for 8 h, the dried Fe 3 o 4 MNPs@Serine;

[0038] (2) The dried Fe 3 o 4 MNPs@Serine was added to ethanol, ultrasonically dispersed at 20kHz for 30min at room temperature, and then Cu(NO 3 ) 2 ·3H 2 O 18g, stirred at 800rmp at 60°C for 24h to obtain Fe-containing 3 o 4 The reaction solution of MNPs@Serine-Cu was cooled to room temperature and Fe was collected by external magnet separation 3 o 4 MNPs@Serine-Cu were washed with 50% ethanol and dried in an oven at 70°C for 6h to obta...

Embodiment 2

[0055] 1. Catalyst Fe 3 o 4 Preparation of MNPs@Serine-Cu

[0056] (1) Preparation of Fe using conventional coprecipitation technique 3 o 4 MNPs11g, then Fe 3 o 4 MNPs were added to deionized water, ultrasonically dispersed at 40 kHz for 35 min, then 16 g of serine was added, stirred at 55 °C at a speed of 900 rpm for 7 h, cooled to room temperature, and the newly formed Fe was collected by magnetic analysis 3 o 4 MNPs@Serine, washed with deionized water, and dried in vacuum at 85 °C for 9 h to obtain the dried Fe 3 o 4 MNPs@Serine;

[0057] (2) The dried Fe 3 o 4 MNPs@Serine was added to ethanol, ultrasonically dispersed at 25kHz for 35min at room temperature, and then Cu(NO 3 ) 2 ·3H 2 O 19g, stirred at 900rmp for 24h at 65°C to obtain Fe-containing 3 o 4 The reaction solution of MNPs@Serine-Cu was cooled to room temperature and Fe was collected by external magnet separation 3 o 4 MNPs@Serine-Cu, washed with 50% ethanol, and dried in an oven at 75°C for 7h, ...

Embodiment 3

[0072] 1. Catalyst Fe 3 o 4 Preparation of MNPs@Serine-Cu

[0073] (1) Preparation of Fe using conventional coprecipitation technique 3 o 4 MNPs12g, then Fe 3 o 4 MNPs were added to deionized water, ultrasonically dispersed at 45kHz for 40min, then 17g of serine was added, stirred at 60°C at a speed of 1000rmp for 8h, cooled to room temperature, and the newly formed Fe was collected by magnetic analysis 3 o 4 MNPs@Serine, washed with deionized water, and dried in vacuum at 90°C for 10 h, the dried Fe 3 o 4 MNPs@Serine;

[0074] (2) The dried Fe 3 o 4 MNPs@Serine was added to ethanol, ultrasonically dispersed at 30kHz for 40min at room temperature, and then Cu(NO 3 ) 2 ·3H 2 O 20g, stirred at 1000rmp for 24h at 70°C to obtain Fe-containing 3 o 4 The reaction solution of MNPs@Serine-Cu was cooled to room temperature and Fe was collected by external magnet separation 3 o 4 MNPs@Serine-Cu, washed with 50% ethanol, and dried in an oven at 80°C for 8h, the catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com