Preparation method of P-doped CuMnCoO4/N-CNs composite material

A technology of composite materials and shrimp shells, which is applied in the field of electrocatalysis, can solve the problems of catalytic reduction reaction kinetics hysteresis, unfavorable large-scale production, and high cost, and achieve excellent electrocatalytic performance, suitable for large-scale production, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

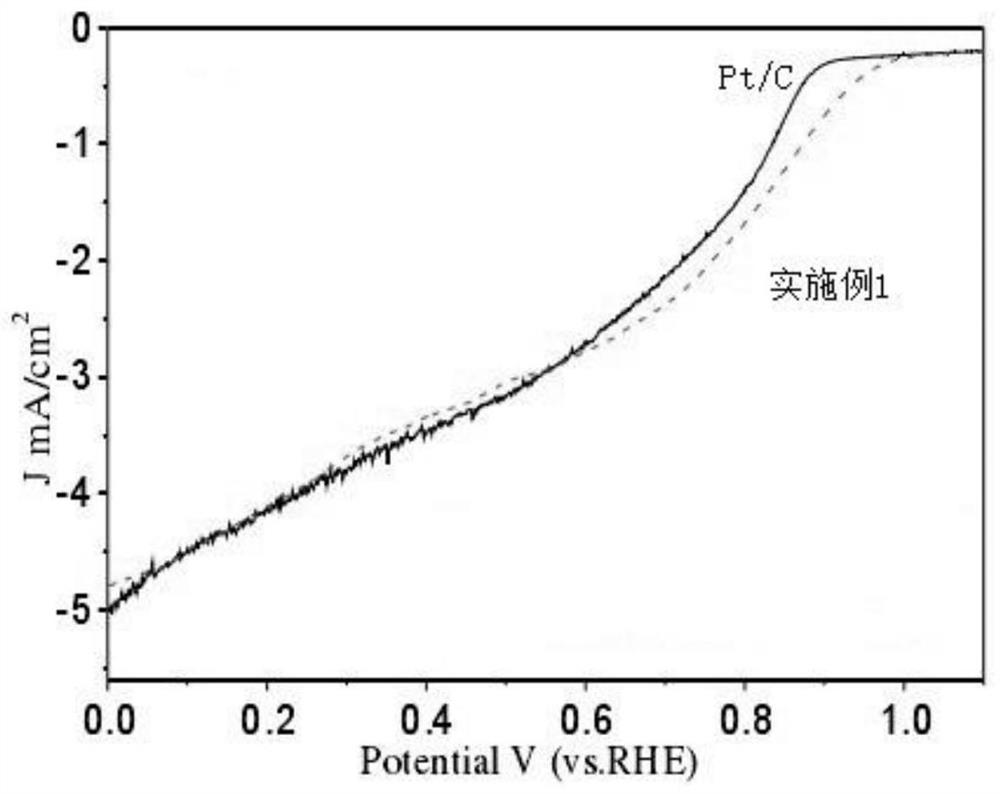

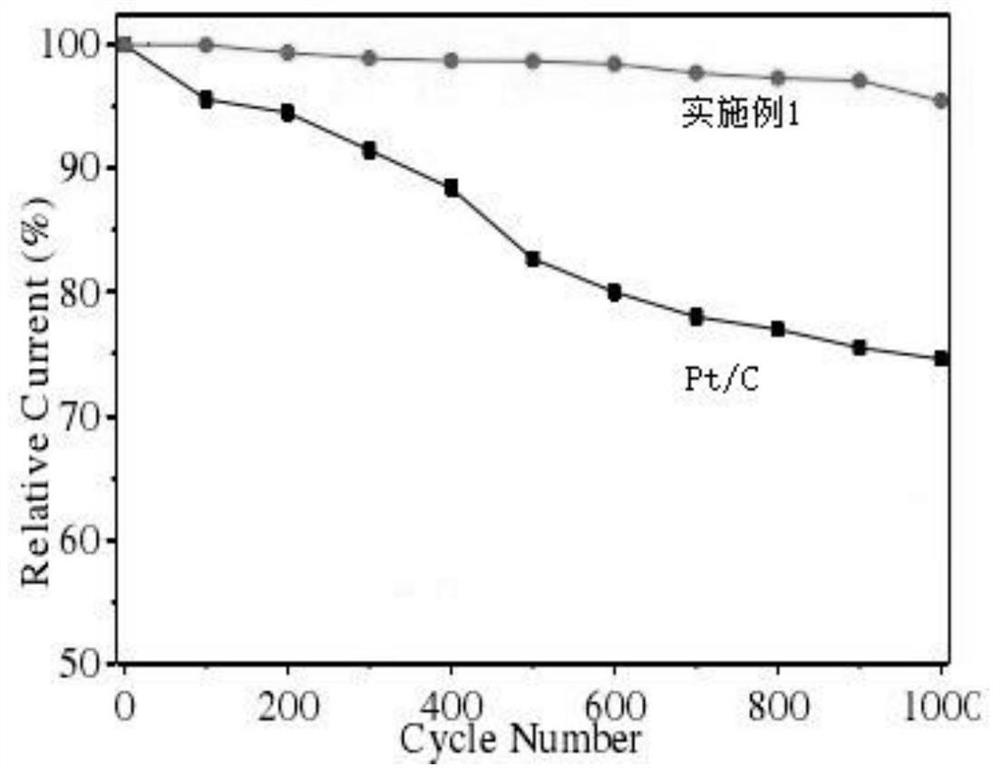

Embodiment 1

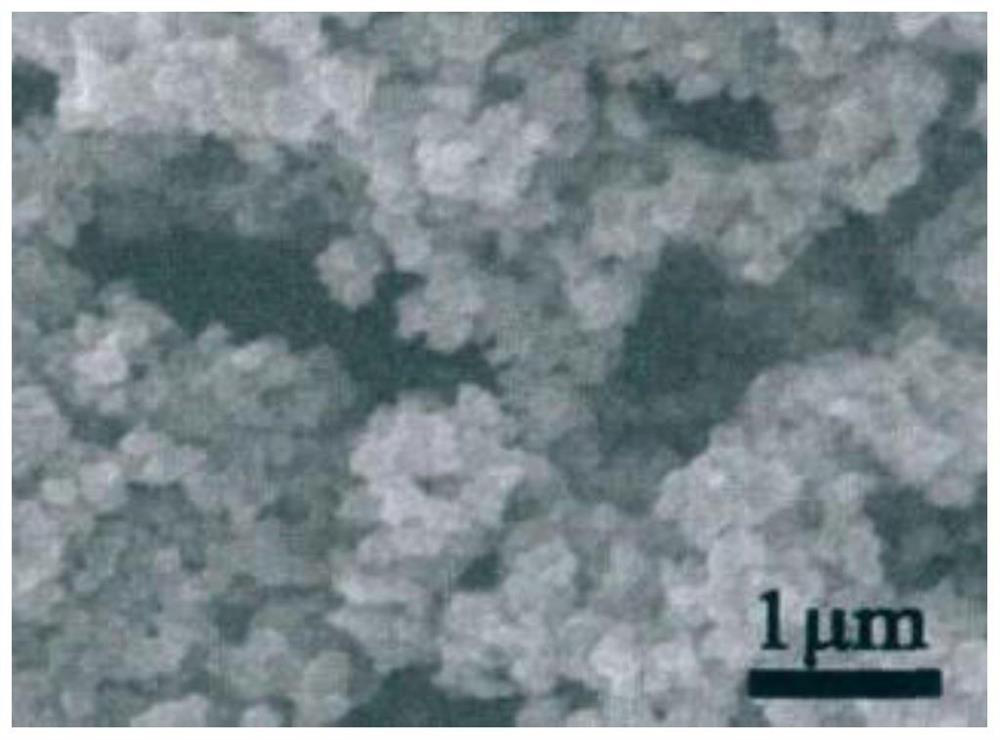

[0023] A P-doped CuMnCoO 4 / N-CNs composite material, specifically including the following preparation steps:

[0024] (1) Dry the shrimp shell at 80°C for 5 hours, then grind it into shrimp shell powder, weigh 1g of the ground shrimp shell powder, put it in the inner tank of the reaction kettle, then add 100ml of deionized water to it and stir evenly , put the reaction kettle in an oven, and heat it with water at 180°C for 15 hours. After the reaction, after cooling to room temperature, the obtained N-CNs solution was filtered with 0.45pm and 0.22pm microporous membranes in order to remove large Shrimp shell residues of large size are centrifuged at 14,000rpm to further separate large particles, and finally a yellow solution of N-CNs solution is obtained;

[0025] (2) Weigh 0.4mmol copper acetate, 0.4mmol cobalt acetate, and 0.4mmol manganese acetate respectively and put them into three test tubes respectively, add 5ml deionized water respectively, and ultrasonically dissolv...

Embodiment 2

[0030] A P-doped CuMnCoO 4 / N-CNs composite material, specifically including the following preparation steps:

[0031] (1) Dry the shrimp shell at 80°C for 5 hours, then grind it into shrimp shell powder, weigh 1g of the ground shrimp shell powder, put it in the inner tank of the reaction kettle, add 150ml of deionized water to it and stir evenly , put the reaction kettle in an oven, and heat it with water at 200°C for 20 hours. After the reaction, after cooling to room temperature, the obtained N-CNs solution was filtered with 0.45pm and 0.22pm microporous membranes to remove large Shrimp shell residues of large size are centrifuged at 14,000rpm to further separate large particles, and finally a yellow solution of N-CNs solution is obtained;

[0032] (2) Weigh 0.4mmol copper acetate, 0.4mmol cobalt acetate, and 0.4mmol manganese acetate respectively and put them into three test tubes respectively, add 5ml deionized water respectively, and ultrasonically dissolve them fully f...

Embodiment 3

[0035] A P-doped CuMnCoO 4 / N-CNs composite material, specifically including the following preparation steps:

[0036] (1) Dry the shrimp shell at 80°C for 5 hours, then grind it into shrimp shell powder, weigh 1g of the ground shrimp shell powder, put it in the inner tank of the reaction kettle, then add 120ml of deionized water to it and stir well , put the reaction kettle in an oven, and heat it with water at 150°C for 10 hours. After the reaction, after cooling to room temperature, the obtained N-CNs solution was filtered with 0.45pm and 0.22pm microporous membranes to remove large Shrimp shell residues of large size are centrifuged at 14,000rpm to further separate large particles, and finally a yellow solution of N-CNs solution is obtained;

[0037] (2) Weigh 0.4mmol copper acetate, 0.4mmol cobalt acetate, and 0.4mmol manganese acetate respectively and put them into three test tubes respectively, add 5ml deionized water respectively, and ultrasonically dissolve them full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com