A production and processing system for absorbent melt-blown cloth

A processing system and technology of melt-blown cloth, applied in the direction of melt spinning, non-woven fabrics, spinneret assemblies, etc., can solve problems such as nozzle blockage, and achieve the effects of solving blockage, good sealing, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

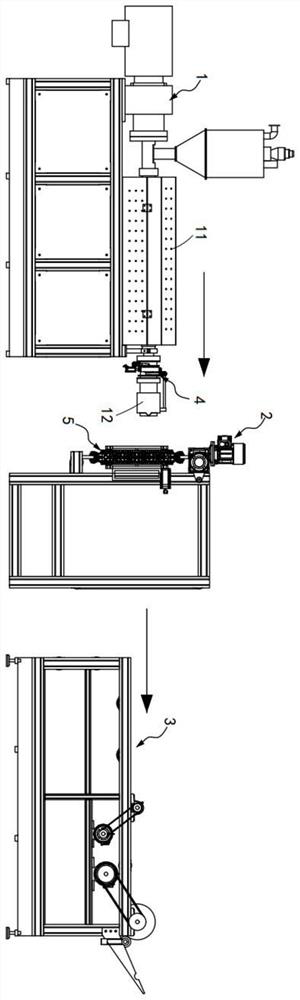

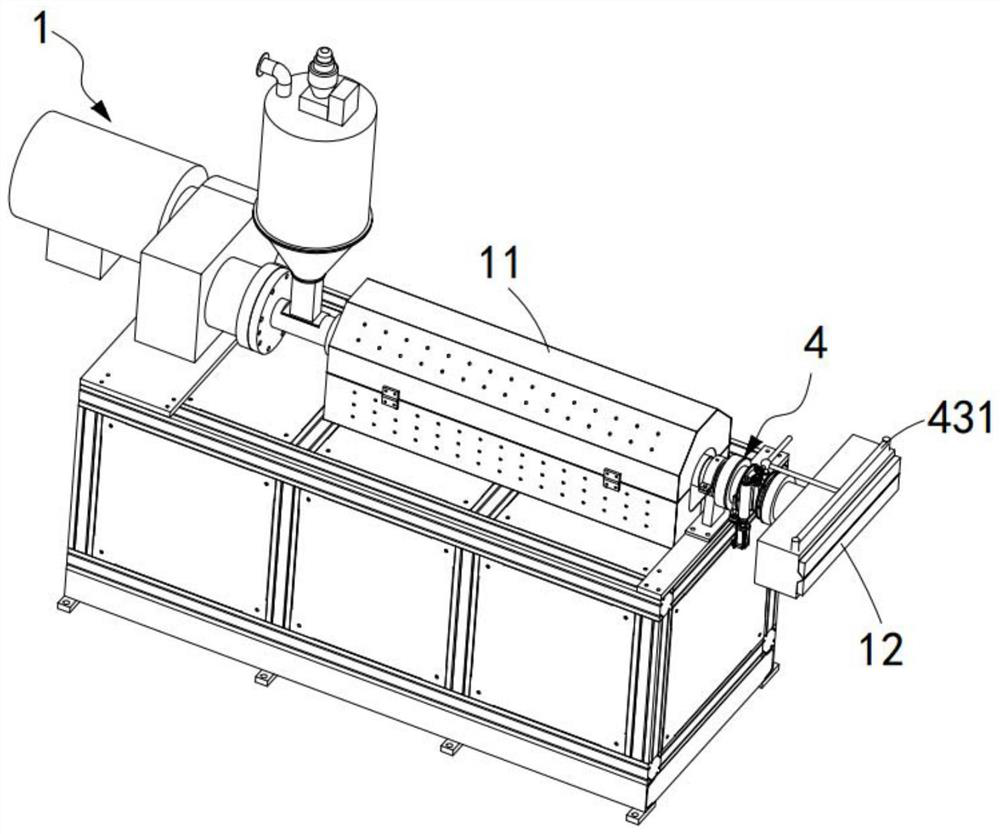

[0079] like Figures 1 to 11 As shown, an absorbent melt-blown cloth production and processing system includes a melt-blown device 1, a negative pressure forming device 2 and a rolling device 3 along the processing and forming direction of the melt-blown cloth. The melt-blown device 1 is used to spray out The fiber filaments used to form the melt-blown cloth are composed of a screw extrusion mechanism 11 and a spray head 12. The negative pressure forming equipment 2 is used to absorb the fiber filaments to form a melt-blown cloth, and a rotating forming belt 21 is arranged on it. The rolling device 3 is used for winding the melt-blown cloth,

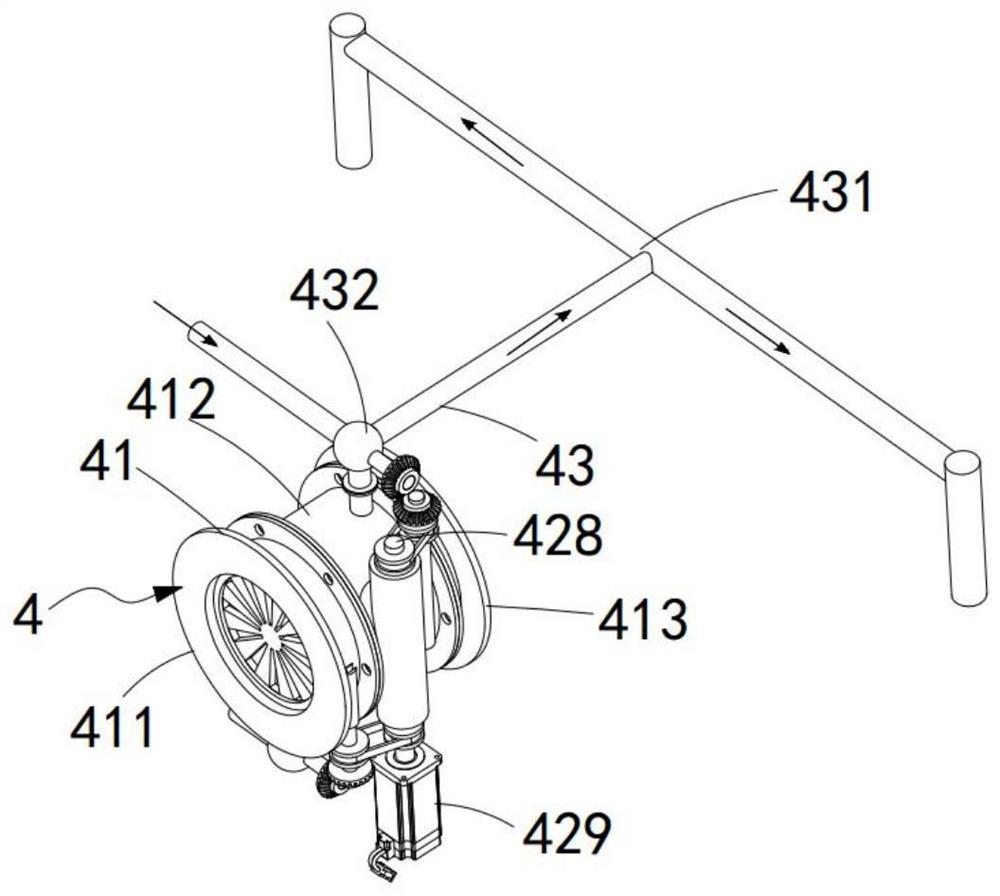

[0080] A cleaning assembly 4 is provided between the screw extrusion mechanism 11 and the spray head 12, and the cleaning assembly 4 includes an outer cylinder group 41, an inner cylinder group 42 and an air sweep mechanism 43. The outer cylinder group 41 The two ends of the screw extrusion mechanism 11 and the spray head 12 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com