Biomass direct liquefaction reactor, reactor system and biomass direct liquefaction method

A reactor system and reactor technology, which are used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils, can solve problems such as difficult separation and complex components, and achieve reduced gas-liquid ratio, low product oxygen content, Beneficial for deep deoxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

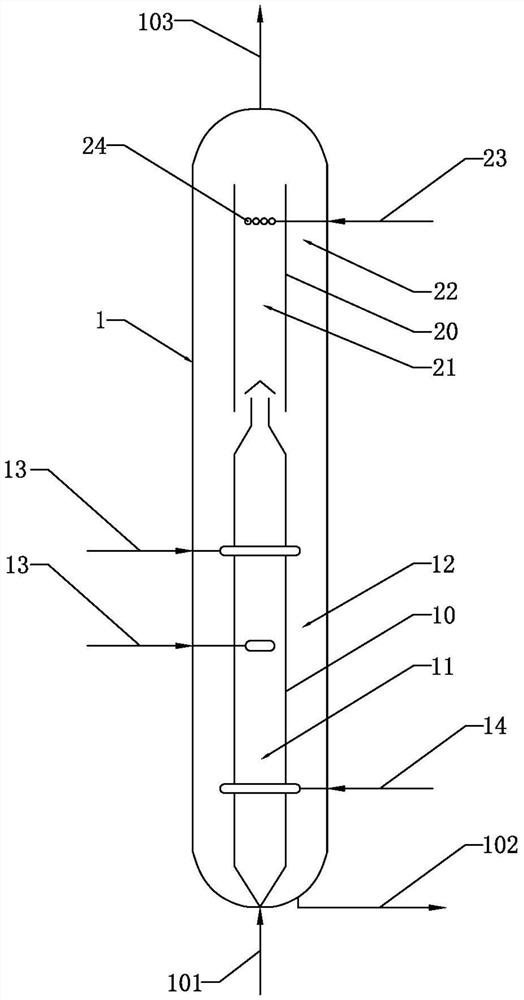

[0037] See figure 1 , a biomass direct liquefaction reactor, the liquefaction reactor includes a reactor shell 1 and a reaction zone and a separation zone arranged in the reactor shell 1, the reaction zone is located in the lower part of the reactor shell 1, separated The zone is located in the upper part of the reactor shell 1, the bottom of the reactor shell 1 is provided with a raw material inlet 101 and a first product outlet 102, and the top of the reactor shell is provided with a second product outlet 103;

[0038] The reaction zone is divided into a primary reaction zone 11 and a secondary reaction zone 12 by the first built-in sleeve 10, and the primary reaction zone 11 located in the first built-in sleeve 10 is the primary reaction zone 11 under the syngas atmosphere, where the liquefaction reaction of biomass takes place; The secondary reaction zone 12 is located between the first built-in sleeve 10 and the reactor shell 1, and performs a hydrodeoxygenation reaction ...

Embodiment 2

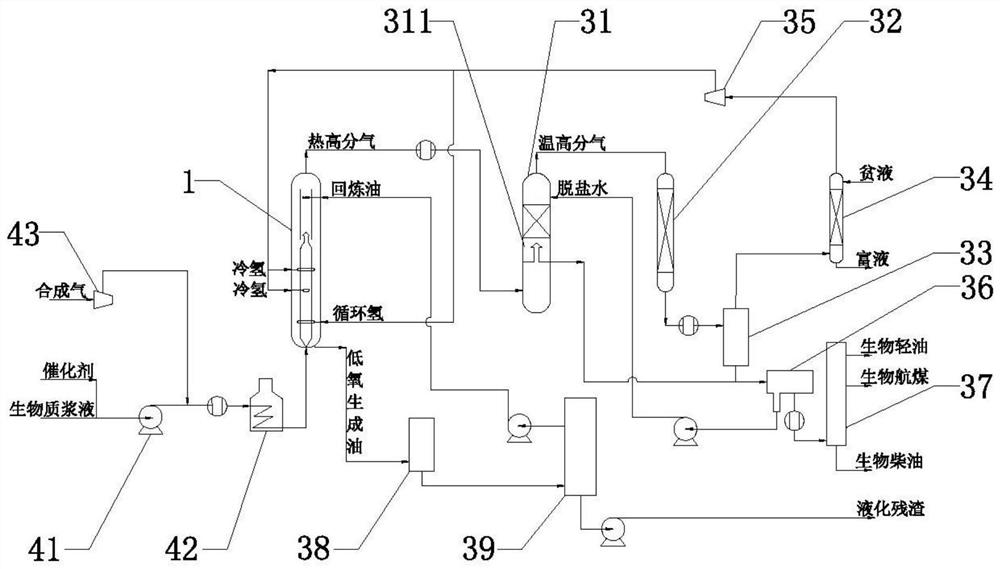

[0043] See figure 2 , a biomass direct liquefaction reactor system, the reactor system includes the above-mentioned liquefaction reactor.

[0044] In this embodiment, the reactor system also includes a raw material delivery unit, the raw material delivery unit includes a booster pump 41, a new hydrogen compressor 42 and a heating furnace 43, and the inlets of the booster pump 41 are respectively connected to the biomass slurry delivery pipe , the catalyst delivery pipe, the inlet of the new hydrogen compressor 42 is connected to the synthesis gas delivery pipe, the inlet of the heating furnace 43 is connected with the outlet of the booster pump 41 and the outlet of the new hydrogen compressor 42 respectively, and the outlet of the heating furnace 43 is connected with the liquefaction reactor The raw material inlet 101 is connected.

[0045] In this embodiment, the reactor system further includes a product separation unit, and the product separation unit includes a warm and h...

Embodiment 3

[0049] A biomass direct liquefaction method based on the reactor system described above. The biomass slurry and the catalyst are boosted by a pump, mixed and heated with the boosted syngas, and then enter the raw material inlet of the liquefaction reactor, in the primary reaction zone 11 After the liquefaction reaction is completed, the gas phase enters the primary reaction oil-gas separation zone 21, and the liquid phase enters the secondary reaction zone 12 for further hydrodeoxygenation reaction;

[0050] After the primary reaction oil and gas are in countercurrent contact with the low-temperature re-refined oil in the primary reaction oil-gas separation zone 21, the high-boiling point oxygen-containing compounds are condensed, and the uncondensed oil and gas are mixed with the oil and gas in the secondary reaction oil-gas separation zone 22. The second product outlet 103 of the device is derived.

[0051] The reaction oil gas derived from the second product outlet 103 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com