Production process for improving yield of hexazinone

A production process, the technology of hexazinone, applied in the field of hexazinone, can solve the problems of incomplete reaction of raw materials, low yield of raw material products of hexazinone, etc., achieve uncomplicated reaction principle, practical control of reaction process, and reduce residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

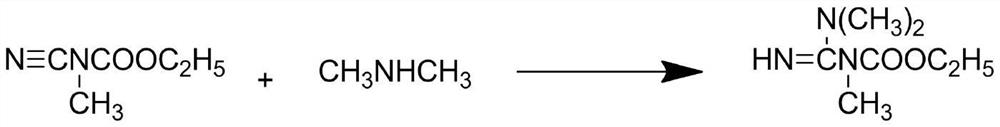

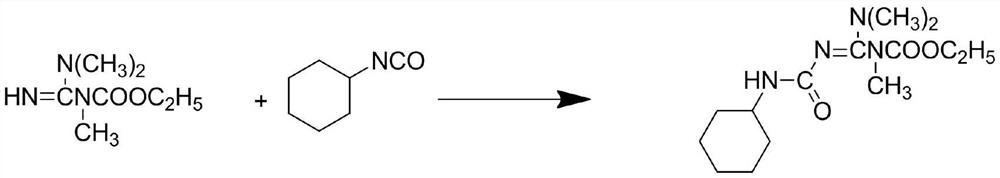

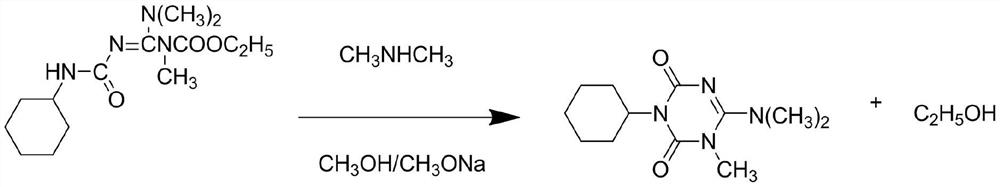

[0036] A production technique for improving the yield of hexazinone, specifically comprising the following steps:

[0037] Step S1, synthesis of methyl products: first add 1.1 parts by weight of cyanamide to the methylation kettle, add 64 parts by weight of liquid caustic soda and 3 parts by weight of ethyl chloroformate into the metering tank, and then open the methylation kettle After the temperature in the methylation kettle is lowered to 0°C, add liquid caustic soda and ethyl chloroformate dropwise to the methylation kettle, and control the temperature in the kettle to 2°C. After the addition of ethyl chloroformate is completed, Measure the pH value in the methylation kettle, when the pH value is stable at 8, stop dripping liquid caustic soda, and close the freezing valve of the methylation kettle; open the jacket water and steam inlet and outlet valves, Carry out heating, when heating up to 38 ℃, keep warm for 4h, stabilize the pH value in the methylation kettle by drippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com