Modified planar current collector, preparation method thereof, lithium electrode and lithium battery

A planar set and fluid technology, applied in the direction of lithium batteries, electrode carriers/collectors, non-aqueous electrolyte batteries, etc., can solve the problems of large influencing factors and difficulty in preparing thin-layer lithium uniformly, so as to achieve uniform electric field distribution and easy repeatability Homogenized preparation and uniform flux of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The isolated heterojunction in the embodiment of the present invention is to achieve prepared, uniform patterned heterojunction as a lithium substance using a template such as a mask plate. Embodiments of the present invention provide a method of preparing a modified planar collector as described above, including the following steps:

[0036]The mask is constructed in the plane of the surface collective heterogeneous lithium region, and the mode of constructing the heterojunction of the pattern can be sputtering, or the simplified manner of plasma etching can also achieve the regulation of the substrate surface energy. To achieve a more uniform and dense deposition.

[0037]In some embodiments of the present invention, the sputtering layer is more lithium properties (such as graphe slurry, gold, silver, tin, or) by a mask plate. Array pattern of metal oxides, etc.).

[0038]Wherein, the reticle is a hollow array template, where a single pattern can be round or square, etc., and the spa...

Embodiment 1

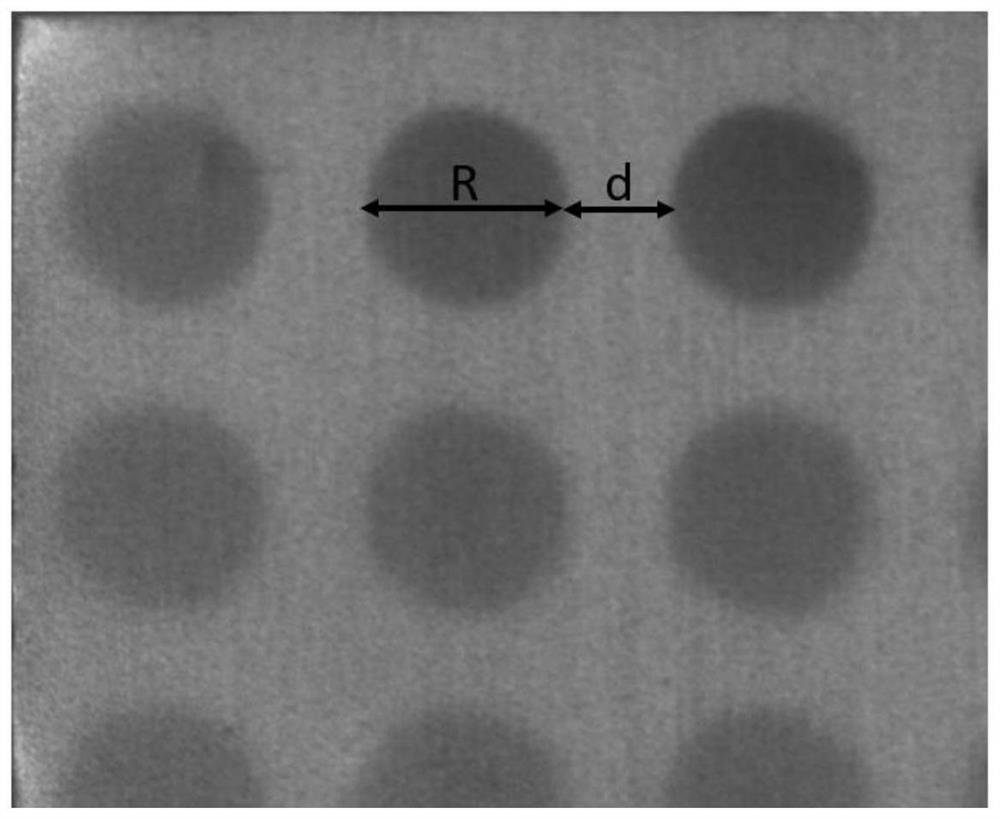

[0045]Through the mask (the pattern is circular), a layer of material that is more lithium-philic than copper foil is sputtered on the copper foil (sputtering vacuum state 4*10-2mbar; the lithium-philic substance selected in Example 1 is gold), the formation is asfigure 1 In the patterned heterojunction array shown, the distance d between adjacent patterned heterojunctions is 0.5 of the lateral dimension R of the pattern, that isfigure 1 In d / R=0.5. Based on the area ratio of the planar current collector being 1, the area ratio of the patterned heterojunction region is 0.8.

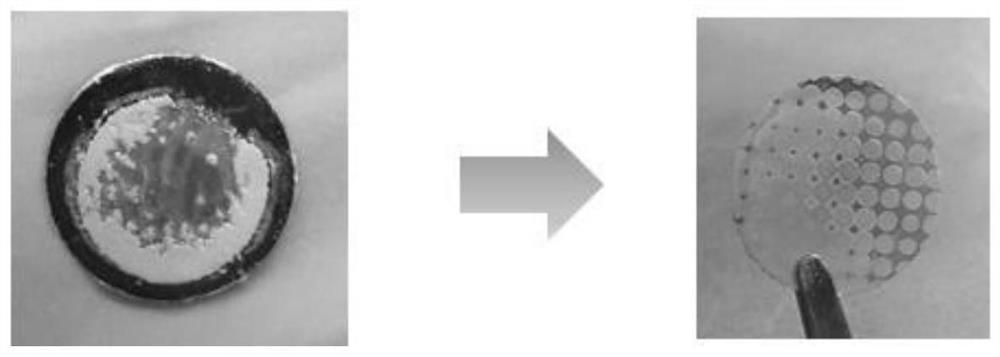

[0046]The obtained patterned current collector is subjected to electrodeposition of lithium to obtain a dense lithium foil with a controllable capacity. At 1mA / cm2The current density is deposited for 1h of lithium deposition for effect comparison, such asfigure 2 Shown.figure 2 On the left is the effect of unmodified current collector lithium deposition, you can see the uneven deposition, as well as the exposed un...

Embodiment 2

[0050]Through the mask (the pattern is circular), a layer of material that is more lithium-philic than copper foil is sputtered on the copper foil (sputtering vacuum state 4*10-2mbar; the lithium-philic substance selected in Example 2 is gold), the formation is asFigure 5 In the patterned heterojunction array shown, the spacing between the patterned heterojunctions is 0.25 of the lateral dimension of the pattern, that isFigure 5 Middle d / R=0.25. Based on the area ratio of the planar current collector being 1, the area ratio of the patterned heterojunction region is 0.8.

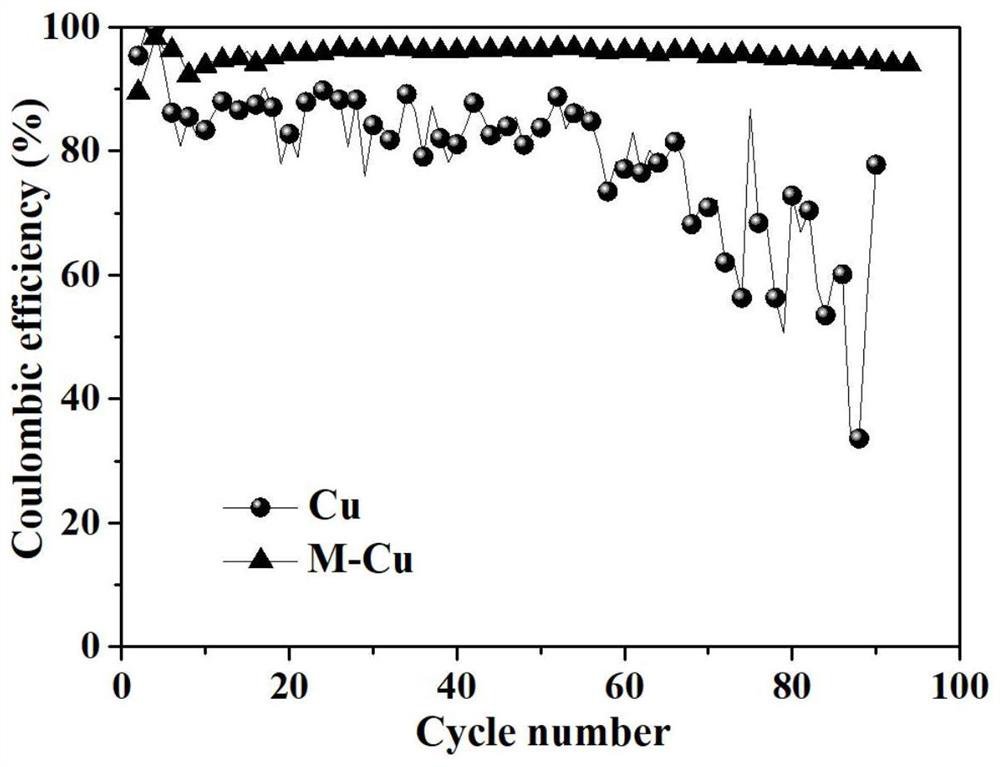

[0051]The obtained patterned current collector is subjected to electrodeposition of lithium to obtain a dense lithium foil with a controllable capacity. The difference between this embodiment and embodiment 1 is that the spacing between patterned heterojunctions is 0.25 of the lateral dimension of the pattern, and the lithium deposition effect is as followsFigure 6 As shown, the lithium deposition is more uniform than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com