A kind of bifidobacterium powder and the preparation technology of probiotics thereof

A technology of bifidobacteria and probiotics, applied in the directions of bifidobacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of complex preparation process and low survival rate of bifidobacteria, so as to improve the survival rate, Produce maneuverable, fast-acting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

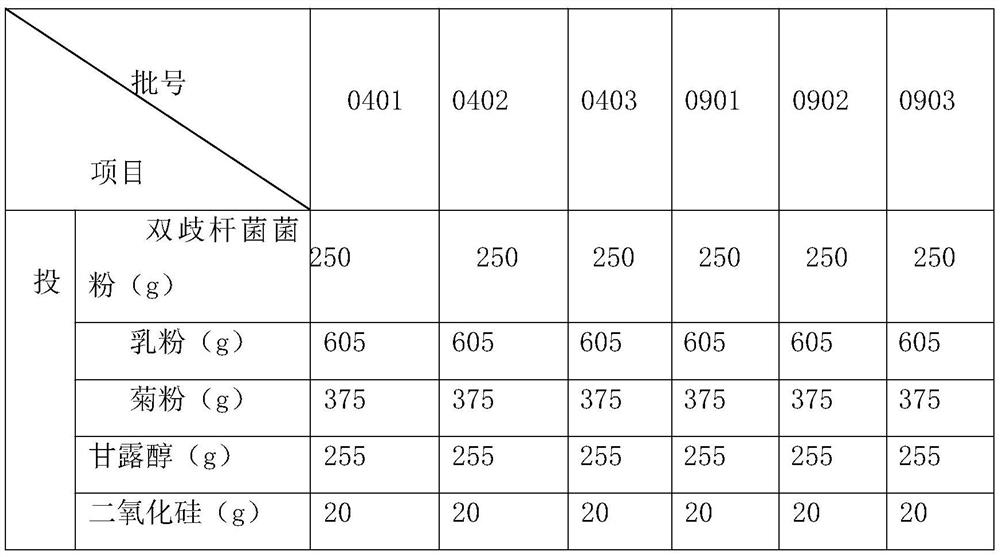

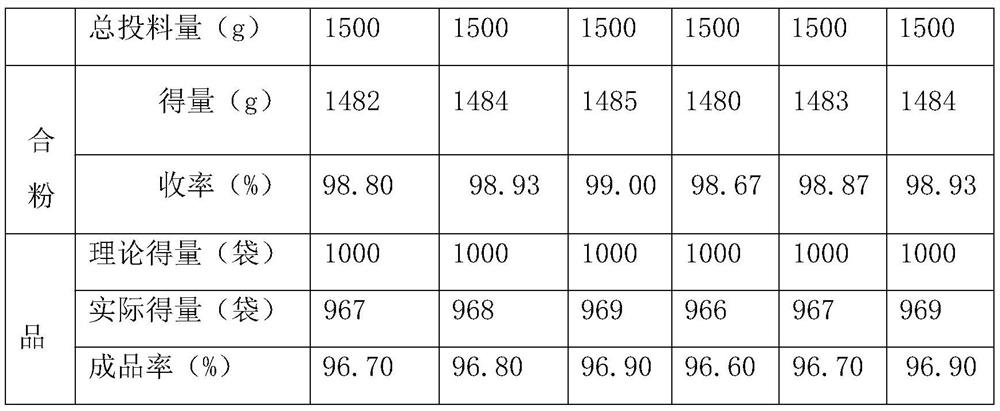

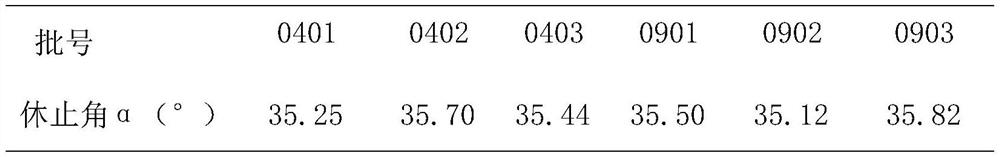

Examples

Embodiment 1

[0039] Bifidobacterium species: Chr. Hansen BB-12.

[0040] Inoculate Bifidobacterium BB-12 in TPY medium with 5% inoculation amount, and culture it at 37±1°C for 24 hours under anaerobic conditions, then at 4°C, 6000r·min -1 Centrifuge for 15 minutes, discard the supernatant, wash the cells with sterilized distilled water, and then centrifuge again under the same conditions to obtain bifidobacteria cells.

[0041] The obtained bacterial cells and the dry protection agent were mixed uniformly according to the weight-to-volume ratio (1:100g / mL). The formula of the above-mentioned spray-drying matrix is: 10g of skim milk powder, 7g of maltose by weight, 1.5g of calcium hydrogen phosphate, 0.4g of poloxamer, and 81.1g of water.

[0042] Spray-dry the mixed liquid obtained in the previous step. The spray-dried conditions are as follows: the bacterial cell mixed liquid is dried by a spray dryer at a speed of 5ml / min, the inlet temperature is 140°C, and the outlet temperature is 55°C...

Embodiment 2

[0045] The formulation of the spray-drying matrix is: 10 g of skimmed milk powder, 7 g of trehalose by weight, 1.5 g of calcium hydrogen phosphate, 0.4 g of poloxamer, and 81.1 g of water. Other operating conditions are with embodiment 1. Bifidobacteria survival rate: 52.8%.

Embodiment 3

[0047] The formulation of the spray-drying matrix is: 10 g of skimmed milk powder, 7 g of sucrose by weight, 1.5 g of calcium hydrogen phosphate, 0.4 g of poloxamer, and 81.1 g of water. Other operating conditions are with embodiment 1. Bifidobacteria survival rate: 55.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com