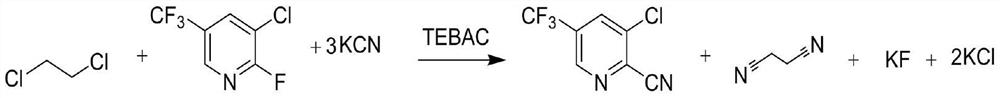

Combined preparation method of 2-cyano-3-chloro-5-trifluoromethylpyridine and succinonitrile

A technology of trifluoromethyl pyridine and combined preparation, which is applied in cyanide reaction preparation, carboxylic acid nitrile purification/separation, organic chemistry and other directions, can solve the problems of large amount of waste water and difficult treatment, and achieves less waste water and easy treatment. , Easy to recycle and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027](98%) (98%) of potassium pelicide particles 132.5 g (1.995 mol) and 300 g (16.7 mol) were added, stirred until completely dissolved. Further, 4-dimethylaminopyridine 3.7 g (0.025 mol), 394.8 g (3.989 mol) and 2-fluoro-3-chloro-5-trifluoromethylpyridine 200g (0.997 mol) were added.

[0028]Then the stirring was evenly stirred to a reflux reaction for 12 h, and the temperature of the reaction liquid is 0.2 ppm, the reaction liquid is lowered to 30-35 ° C, and the lower layer is the product mixture (the aqueous layer is added. After the chloroethane, stir, stand in the layers, and the dichloroethane layer is used for the next batch reaction). The product mixed was mixed with dichloroethane at normal pressure to prepare dichloroethane 285 g. Then the pamiditrile was minipitricile at 3 kPa vacuum to give 66.0 g of butidonitrile, and the content was 99.9%. Dikinonitrile and 2-cyano-3 chloro-5-trifluoromethylpyridine transition fraction 22.3g analysis of butonlonitrile content 41.3%, 2-...

Embodiment 2

[0030]Under the conditions of room temperature, (98%) of (98%) of potassium particles 132.5 g (1.995 mol) and 300 g (16.7 mol) were added, stirred until completely dissolved in a 1000 ml of tetra-mouth flask. The benzyl triethyl chloride was added 5.7 g (0.025 mol), 394.8 g (3.989 mol) and 2-fluoro-3-chloro-5-trifluoromethylpyridine (0.997 mol).

[0031]Then the stirring was mixed and then raised to 75-78 ° C for refluxing reaction for 10 h, and the temperature of the reaction liquid is 0.2 ppm, and the reaction liquid is lowered to 30-35 ° C, stand in the layered, the lower layer is a product mixture (the aqueous layer added to the second After the chloroethane, stir, stand in the layers, and the dichloroethane layer is used for the next batch reaction). The product mixture was mixed with dichloroacethane atmospheric pressure, and then pamiditrile was minimalized at 3 kPa vacuum to give 68.3 g of butidonitrile, the content was 99.9%. Dikinnitrile and 2-cyano-3-chloro-5-trifluoromethyl...

Embodiment 3

[0033](98%) (98%) of potassium pelicide particles 132.5 g (1.995 mol) and 300 g (16.7 mol) were added, stirred until completely dissolved. Further, 4-dimethylaminopyridine 3.7 g (0.025 mol) was added, and 394.8 g (3.989 mol) and 2-fluoro-3-chloro-5-trifluoromethylpyridine (0.997 mol) were recovered. .

[0034]Then the stirring was evenly stirred to a reflux reaction for 12 h, and the temperature of the reaction liquid is 0.2 ppm, the reaction liquid is lowered to 30-35 ° C, and the lower layer is the product mixture (the aqueous layer is added. After the chloroethane, stir, stand in the layers, and the dichloroethane layer is used for the next batch reaction). The product mixture was distilled at normal pressure to collect dichloroethane to recover dichloroethane. The transition fraction obtained in Example 1 was then 22.3 g (41.3% butbitonitrile content of 41.3%, 2-cyano-3-chloro-5-trifluoromethylpyridine) was added to the distillation tank. Diatronerconitrile was mining at 3 kPa vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com