Oxygenation composite subsurface flow constructed wetland system

A technology of constructed wetland system and subsurface flow wetland, which is applied in the field of compound subsurface flow constructed wetland sewage treatment system, can solve the problems that it is difficult to ensure the dissolved oxygen content of water body and affect the treatment effect, and achieve the purpose of making up for the lack of dissolved oxygen, improving the treatment effect, and huge specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the present invention, the lanthanum-aluminum attapulgite loaded with zero-valent nano-iron is mainly synthesized with attapulgite and hexachloride ferric chloride with a certain particle size. The specific synthesis method and steps are as follows:

[0034] First prepare lanthanum-aluminum attapulgite: grind the natural attapulgite into powder, granulate it, place it in a muffle furnace, calcinate at 700°C for 2 hours, add 3 (0.2mol / L) and AlCl 3 ·6H 2 O (2mol / L) mixed solution, add the concentration to 4Kg / L, then shake at constant temperature for one hour, take it out, then dry and cool, then wash with ultrapure water, dry at low temperature and cool naturally.

[0035] Loading of zero-valent nano-iron: add lanthanum aluminum attapulgite and hexachloride ferric chloride into ethanol at a mass ratio of 1:1 (both adding concentrations are 40g / L), then stir for 30min, and add dropwise to a volume of ethanol volume 2 Double the sodium borohydride solution, continue ...

Embodiment 1

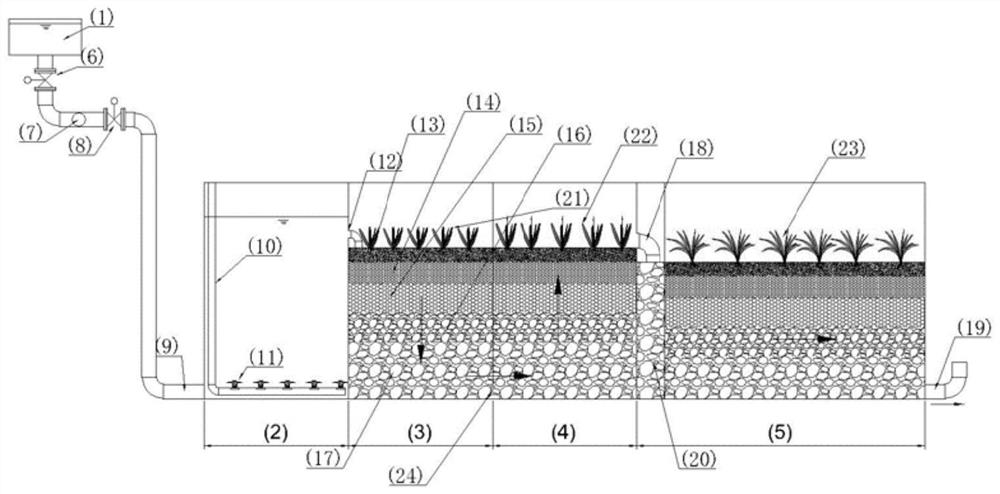

[0048] Such as figure 1 As shown, the total size of the oxygen-increasing composite subsurface flow constructed wetland system in this embodiment is: length×width×height: 500cm×150cm×150cm. Among them, under the condition that the oxygenation pool 2, the downflow wetland 3, the upwelling wetland 4 and the horizontal underflow wetland 5 keep the same width and height, the length of the aeration pool is 100 cm, the length of the downflow wetland is 100 cm, and the length of the uplink wetland is 100cm, and the length of the horizontal subsurface flow wetland is 200cm.

[0049] Composite subsurface flow constructed wetland filler is a mixed filler layer 13 of biochar and fine sand, a biological ceramsite filler layer 14, a lanthanum-aluminum attapulgite filler layer 15 loaded with zero-valent nano-iron, a zeolite filler layer 16, and Gravel packing layer 17, the filling height, density and particle size distribution of each layer are as follows:

[0050] In the downflow wetland...

Embodiment 2

[0058] Such as figure 1 As shown, the total size of the oxygen-increasing composite subsurface flow constructed wetland system in this embodiment is: length×width×height: 500cm×150cm×150cm. Among them, under the condition that the oxygenation pool 2, the downflow wetland 3, the upwelling wetland 4 and the horizontal underflow wetland 5 keep the same width and height, the length of the aeration pool is 100 cm, the length of the downflow wetland is 100 cm, and the length of the uplink wetland is 100cm, and the length of the horizontal subsurface flow wetland is 200cm.

[0059] Composite subsurface flow constructed wetland filler is a mixed filler layer 13 of biochar and fine sand, a biological ceramsite filler layer 14, a lanthanum-aluminum attapulgite filler layer 15 loaded with zero-valent nano-iron, a zeolite filler layer 16, and Gravel packing layer 17, the filling height, density and particle size distribution of each layer are as follows:

[0060] In the downflow wetland...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com