Preparation method for CuFe alloy powder for brake pad

A technology of alloy powder and brake pads, which is applied in the field of preparation of CuFe alloy powder for brake pads, can solve the problems of quality and performance impact of finished products, large difference in melting temperature, difficulty in determining sintering temperature, etc., and improve roundness , small difference in hardness, and the effect of reducing the degree of crystal segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

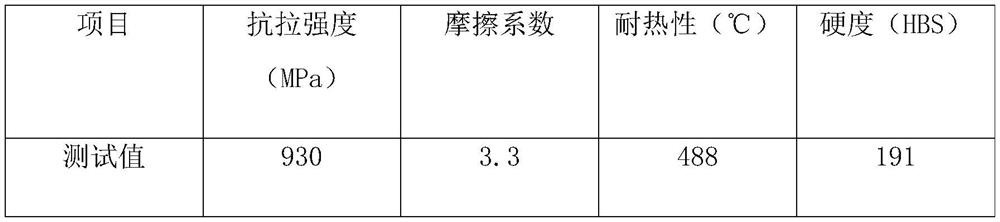

Embodiment 1

[0026] A preparation method of CuFe alloy powder for brake pads, specifically carried out according to the following steps:

[0027] Step 1: Ingredients

[0028] According to the percentage content, adjust the content of the Fe element in the CuFe alloy powder, so that the percentage content of the Fe element is 5% of the entire CuFe alloy powder, and obtain the prepared alloy material;

[0029] Step 2: Load the Furnace

[0030] Put the alloy material prepared in step 1 into the crucible in the vacuum induction melting furnace, close the furnace cover, close the vent valve, and clean the observation window;

[0031] Step 3: Vacuum

[0032] Turn on the mechanical pump, open the low-vacuum damper valve to evacuate, and turn on the Roots pump when the vacuum pressure р=0.08MPa in the furnace;

[0033] Step 4: Smelting

[0034] The crucible used for smelting is a non-carbon crucible; when smelting, when the vacuum degree is pumped to р=4Pa, the heating is raised, the power is ...

Embodiment 2

[0043] A preparation method of CuFe alloy powder for brake pads, specifically carried out according to the following steps:

[0044] Step 1: Ingredients

[0045] According to the percentage content, adjust the content of Fe element in the CuFe alloy powder, so that the percentage content of Fe element is 15% of the whole CuFe alloy powder, and obtain the prepared alloy material;

[0046] Step 2: Load the Furnace

[0047] Put the alloy material prepared in step 1 into the crucible in the vacuum induction melting furnace, close the furnace cover, close the vent valve, and clean the observation window;

[0048] Step 3: Vacuum

[0049] Turn on the mechanical pump, open the low-vacuum damper valve to evacuate, and turn on the Roots pump when the vacuum pressure р=0.05MPa in the furnace;

[0050] Step 4: Smelting

[0051] The crucible selected for smelting is a non-carbon crucible; when smelting, when the vacuum degree is pumped to р=3Pa, the heating is raised, the power is raised...

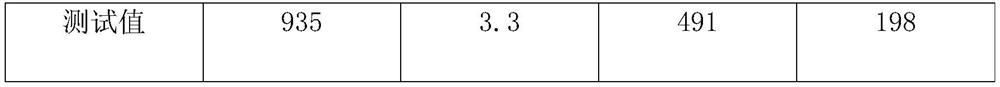

Embodiment 3

[0062] A preparation method of CuFe alloy powder for brake pads, specifically carried out according to the following steps:

[0063] Step 1: Ingredients

[0064] According to the percentage content, adjust the content of the Fe element in the CuFe alloy powder, so that the percentage content of the Fe element is 30% of the entire CuFe alloy powder, and obtain the prepared alloy material;

[0065] Step 2: Load the Furnace

[0066] Put the alloy material prepared in step 1 into the crucible in the vacuum induction melting furnace, close the furnace cover, close the vent valve, and clean the observation window;

[0067] Step 3: Vacuum

[0068] Turn on the mechanical pump, open the low vacuum baffle valve to evacuate, and turn on the Roots pump when the vacuum pressure р=0.01MPa in the furnace;

[0069] Step 4: Smelting

[0070] The crucible used for smelting is a non-carbon crucible; during smelting, when the vacuum degree is pumped to р=1Pa, the heating is raised, the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com