Antioxidant PPS filter material and preparation process thereof

A technology of filter material and preparation process, which is applied in the field of filter felt, can solve the problems of reducing the filtering effect, and achieve the effect of increasing air permeability, high stability and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

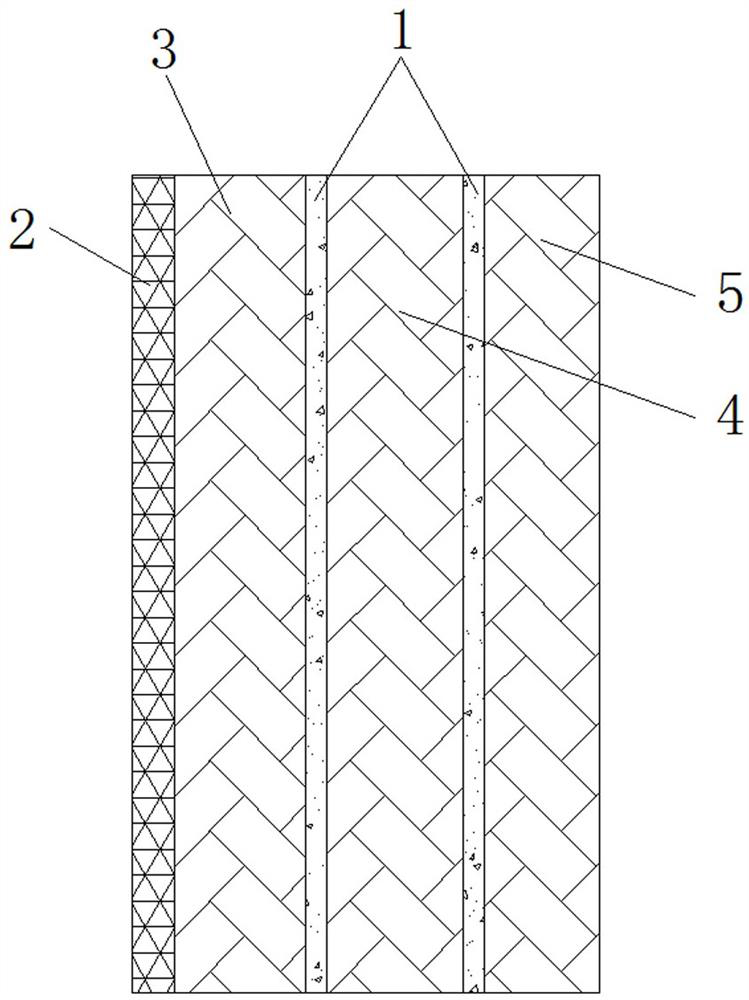

[0039] refer to figure 1 , an antioxidant PPS filter material and its preparation process, S1, preparing electret A1 and electret B2;

[0040] Electret A1 consists of polyethylene, polyurethane, PTFE, silicone and deionized water;

[0041] In electret A1, polyethylene 2%, polyurethane 1%, PTFE 0.5%, silicone 3% and deionized water 85%;

[0042] The preparation step of electret A1 also includes;

[0043] S11. After adding polyethylene, polyurethane, PTFE, and organosilicon into deionized water, use mechanical stirring, the stirring time is 25min, and the stirring frequency is 20Hz;

[0044] S12, applying a voltage of 5Kv to the liquid stirred in S11 for a duration of 3min;

[0045] S13. Evaporate the liquid obtained in the above step S12 at 100° C. until the content of deionized water is reduced to 50%, and finally obtain the electret A1.

[0046] Electret B2 consists of carbon nanofibers, titanium dioxide nanofibers, PTFE, epoxy resin and deionized water;

[0047] Electre...

Embodiment 2

[0065] refer to figure 1 , an antioxidant PPS filter material and its preparation process, S1, preparing electret A1 and electret B2;

[0066] Electret A1 consists of polyethylene, polyurethane, PTFE, silicone and deionized water;

[0067] In electret A1, polyethylene 3%, polyurethane 2%, PTFE 1%, silicone 6% and deionized water 90%;

[0068] The preparation step of electret A1 also includes;

[0069] S11. After adding polyethylene, polyurethane, PTFE and organic silicon into deionized water, use mechanical stirring, the stirring time is 30min, and the stirring frequency is 25Hz;

[0070] S12, applying a voltage of 15Kv to the liquid stirred in S11 for a duration of 5min;

[0071] S13. Evaporate the liquid obtained in the above step S12 at 120° C. until the content of deionized water is reduced to 60%, and finally obtain the electret A1.

[0072] Electret B2 consists of carbon nanofibers, titanium dioxide nanofibers, PTFE, epoxy resin and deionized water;

[0073] Electre...

Embodiment 3

[0091] refer to figure 1 , an antioxidant PPS filter material and its preparation process, S1, preparing electret A1 and electret B2;

[0092] Electret A1 consists of polyethylene, polyurethane, PTFE, silicone and deionized water;

[0093] In electret A1, polyethylene 2.5%, polyurethane 1.5%, PTFE 0.8%, silicone 4% and deionized water 87%;

[0094] The preparation step of electret A1 also includes;

[0095] S11. After adding polyethylene, polyurethane, PTFE, and organosilicon into deionized water, use mechanical stirring. The stirring time is 28min and the stirring frequency is 23Hz;

[0096] S12, applying a voltage of 10Kv to the liquid stirred in S11 for a duration of 4min;

[0097] S13. Evaporate the liquid obtained in the above step S12 at 110-115° C. until the content of deionized water is reduced to 54-56%, and finally obtain the electret A1.

[0098] Electret B2 consists of carbon nanofibers, titanium dioxide nanofibers, PTFE, epoxy resin and deionized water;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com