Enhanced alkali-free setting accelerator as well as preparation method and application thereof

An accelerator and enhanced technology, which is applied in the field of enhanced non-alkali accelerator and its preparation, can solve the problems of restricting the popularization and application of alkali-free accelerator, poor cement adaptability, and poor stability, so as to avoid the increase of void ratio , Improve the strength and accelerate the hardening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

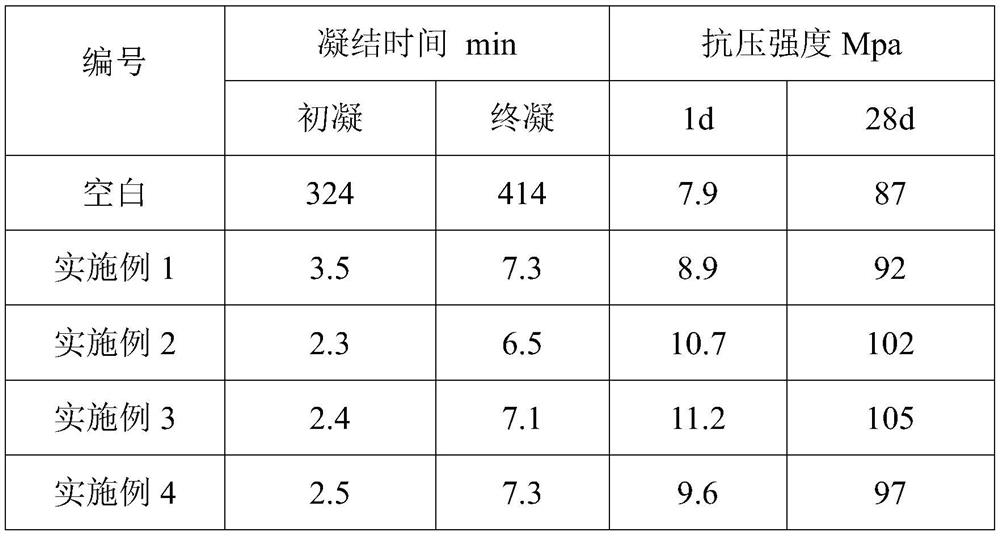

Examples

Embodiment 1

[0024] An enhanced alkali-free quick-setting agent and a preparation method thereof, the raw materials of which are composed of: 24% ionic ammonia aluminum complex solution, 23% aluminum sulfate, 8% stabilizer, 15% enhancer, 1% thickener, Surplus is water, total amount 100%; Said percentage is mass percent;

[0025] The preparation process of the ionic ammonia-aluminum complex solution is as follows: Pour the calculated and weighed pure water with a mass percentage of 65% into a three-necked flask, gradually heat up to 70-80 degrees Celsius in a water bath, and then add a mass percentage of 25% nitric acid Two-thirds of the aluminum was added into the three-necked flask and stirred for 20 minutes to obtain a substantially clear solution. Then slowly add diethanol monoisopropanolamine with a mass percentage of 10% to the system, keep stirring for 20 minutes, then slowly add the remaining aluminum nitrate into the three-necked flask and stir until the solution is clear and trans...

Embodiment 2

[0028] An enhanced alkali-free quick-setting agent and a preparation method thereof, the raw materials of which are composed of: 24% ionic ammonia-aluminum complex solution, 28% aluminum sulfate, 8% stabilizer, 17% enhancer, 3% thickener, Surplus is water, total amount 100%; Said percentage is mass percent;

[0029] The preparation process of the ionic ammonia-aluminum complex solution is as follows: Pour the calculated and weighed pure water with a mass percentage of 65% into a three-necked flask, gradually heat up to 70-80 degrees Celsius in a water bath, and then add a mass percentage of 25% nitric acid Two-thirds of the aluminum was added into the three-necked flask and stirred for 20 minutes to obtain a substantially clear solution. Then slowly add diethanol monoisopropanolamine with a mass percentage of 10% to the system, keep stirring for 20 minutes, then slowly add the remaining aluminum nitrate into the three-necked flask and stir until the solution is clear and trans...

Embodiment 3

[0032] An enhanced alkali-free quick-setting agent and a preparation method thereof. The raw materials are as follows: 22% ionic ammonia-aluminum complex solution, 25% aluminum sulfate, 7% stabilizer, 15% enhancer, 1% thickener, Surplus is water, total amount 100%; Said percentage is mass percent;

[0033] The preparation process of the ionic ammonia-aluminum complex solution is as follows: Pour the calculated and weighed pure water with a mass percentage of 65% into a three-necked flask, gradually heat up to 70-80 degrees Celsius in a water bath, and then add a mass percentage of 25% nitric acid Two-thirds of the aluminum was added into the three-necked flask and stirred for 20 minutes to obtain a substantially clear solution. Then slowly add diethanol monoisopropanolamine with a mass percentage of 10% to the system, keep stirring for 20 minutes, then slowly add the remaining aluminum nitrate into the three-necked flask and stir until the solution is clear and transparent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com