Method for assembling quantum dot laser on planar superlattice nanowire

A superlattice and nanowire technology, applied in the field of semiconductor devices, can solve the problem that colloidal quantum dots cannot be positioned accurately, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

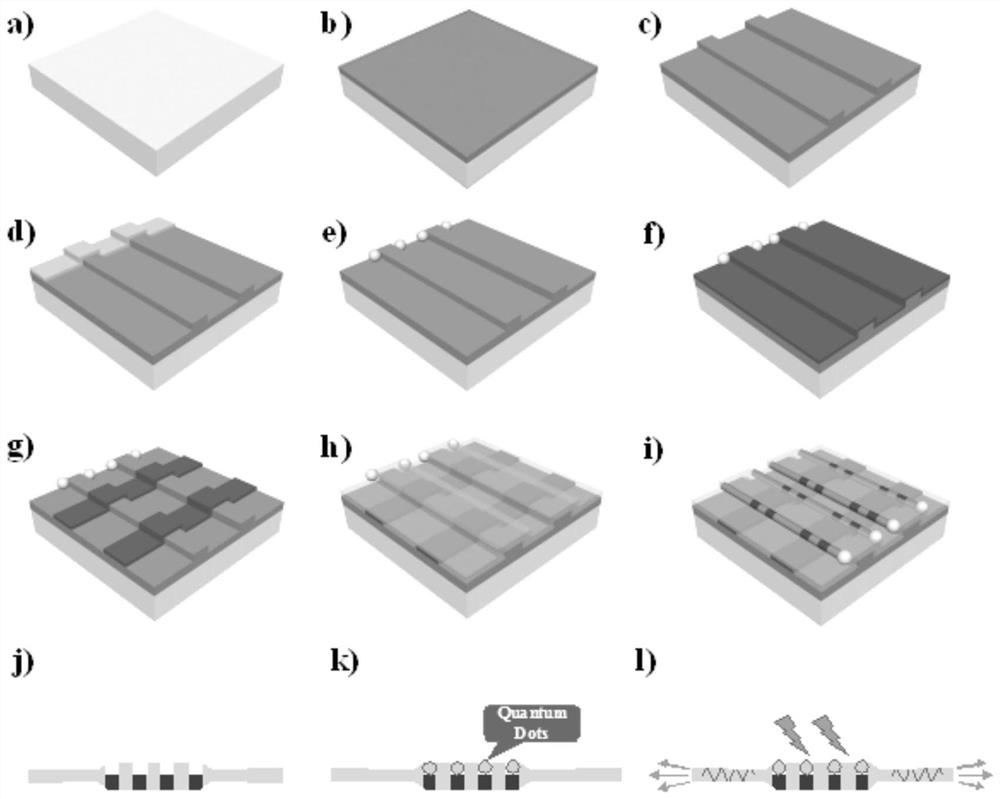

[0028] Such as figure 1 As shown, this embodiment provides a method for assembling a quantum dot laser on a planar superlattice nanowire, which specifically includes the following steps:

[0029] 1) Deposit a layer of insulating medium after pretreatment of the substrate material

[0030] Such as figure 1 (a), figure 1 As shown in (b): the substrate in this embodiment can be crystalline silicon, glass, aluminum foil, silicon nitride, silicon oxide, silicon carbide, sapphire, PI (polyimide) or PET (polyterephthalic acid) Plastic), using PECVD or PVD process to deposit a layer of 200~1000nm thick insulating dielectric layer.

[0031] Preferably, in this embodiment, an insulating dielectric layer with a thickness of 100-600 nm is deposited, and the material of the insulating dielectric layer is silicon oxide or silicon nitride.

[0032] ) Etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Covering thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com