Cold-rolled electromagnetic steel plate for rapid cycling synchrotron and manufacturing method thereof

An electromagnetic steel plate, cycle synchronization technology, applied in the field of cold-rolled electromagnetic steel plate, can solve the problems of affecting the fast cycle synchrotron, poor processing performance and stability, increasing the hardness of pure iron plates, etc., to achieve production cost competitiveness and reduce coercivity. , the effect of promoting grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] The present invention will be described in more detail below in conjunction with the embodiments.

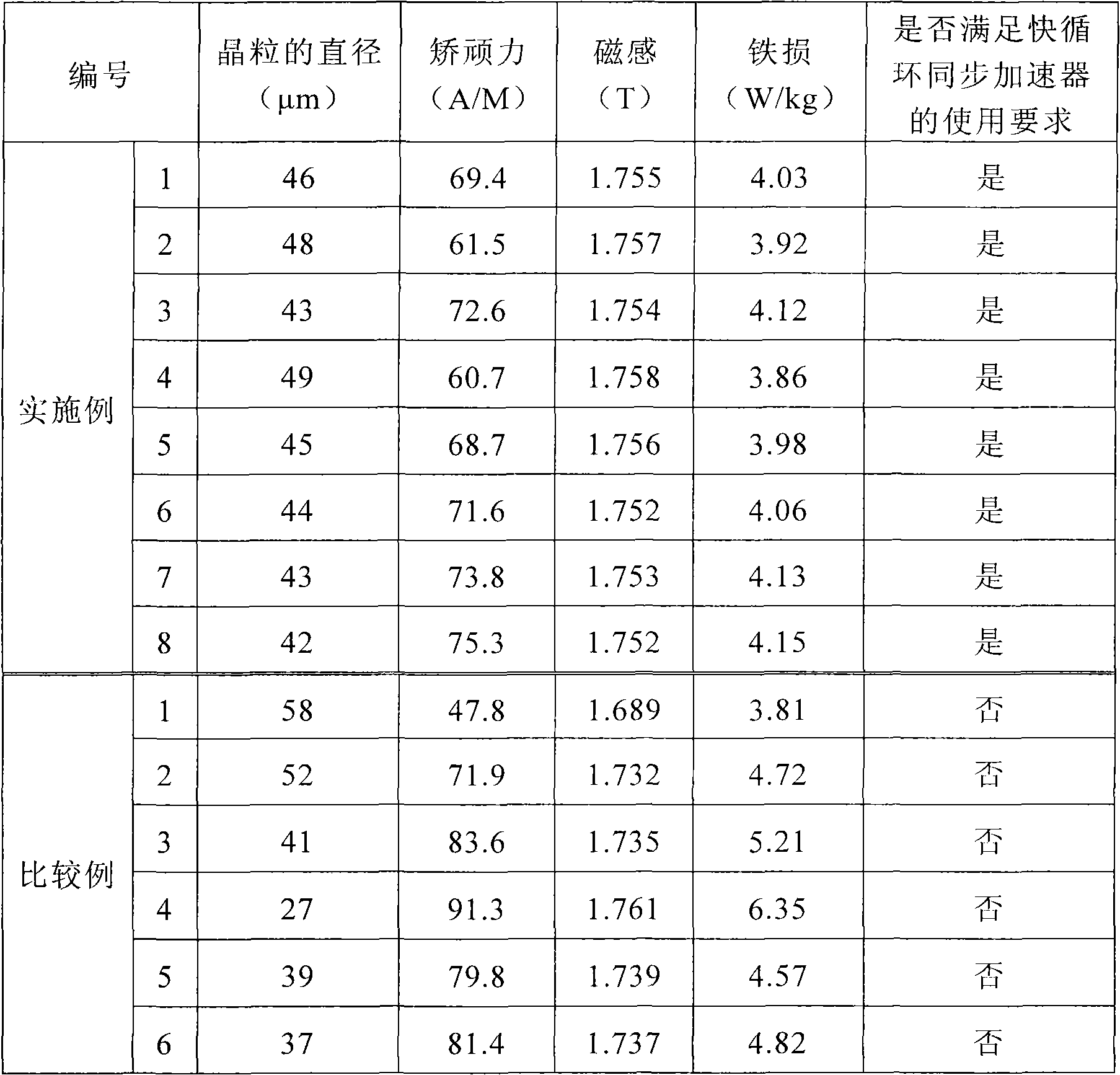

[0043] The main chemical components of the steel involved in the embodiment of the present invention and the steel involved in the comparative example are shown in Table 1.

[0044] After the molten steel is subjected to converter, RH refining treatment, pouring into billets, after hot rolling, normalization, acid precipitation, cold rolling, annealing, and coating, non-oriented electrical steel products are obtained. Among them, the slab is hot-rolled into a 2.6mm strip; then the 2.6mm hot-rolled strip is subjected to normalization treatment, the normalization temperature is controlled at 970℃, and the normalization time is controlled at 30S~60S; after the normalization treatment The strip steel is cold-rolled into a 0.5mm strip steel, and then subjected to final annealing and coating. The final annealing temperature after cold rolling is 850°C, and the annealing time is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com