Self-reinforced anti-seepage outer wall

A self-replenishing technology for exterior walls, applied to walls, building components, building insulation materials, etc., can solve problems such as high cost, potential safety hazards, and impact on wall strength, and achieve the effects of improving strength, improving safety, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

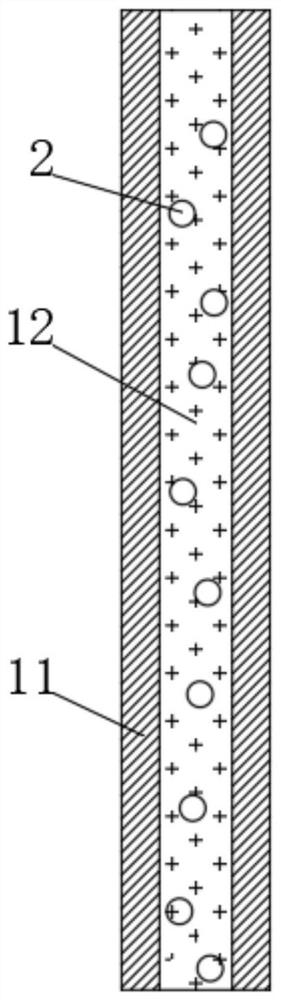

[0039] see figure 1 , a self-reinforced anti-seepage exterior wall, comprising two waterproof layers 11 and a concrete layer 12 fixedly poured between the two waterproof layers 11, the interior of the concrete layer 12 is evenly embedded with a plurality of uniformly distributed self-setting balls 2 .

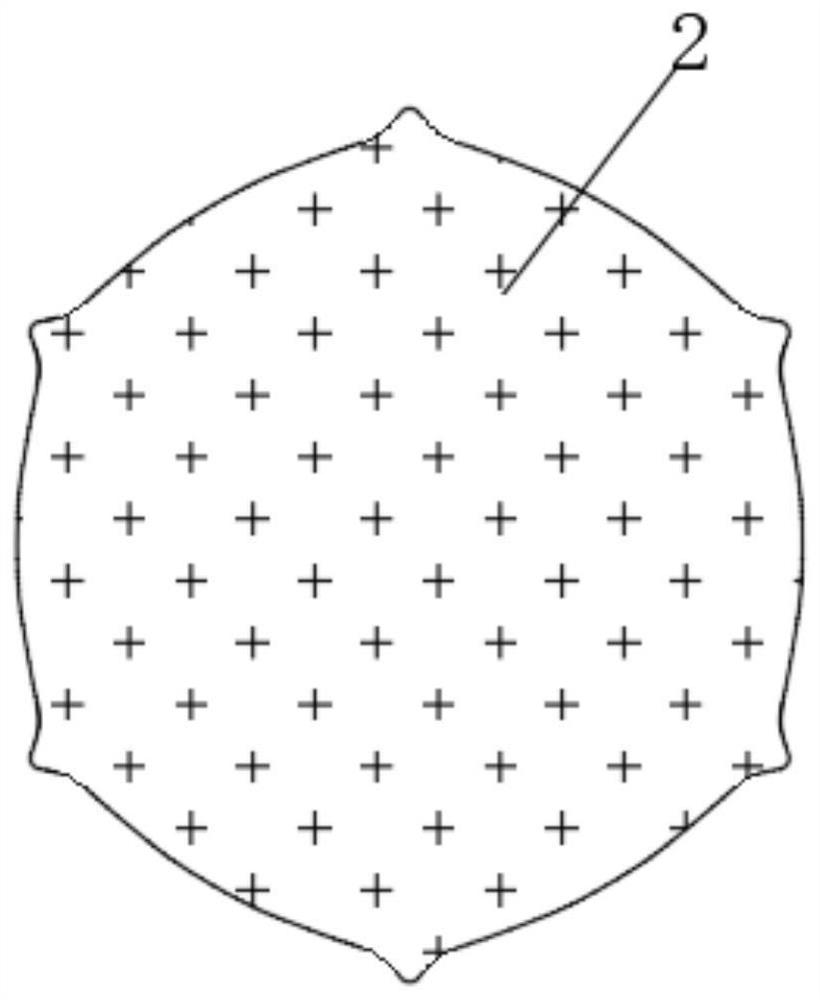

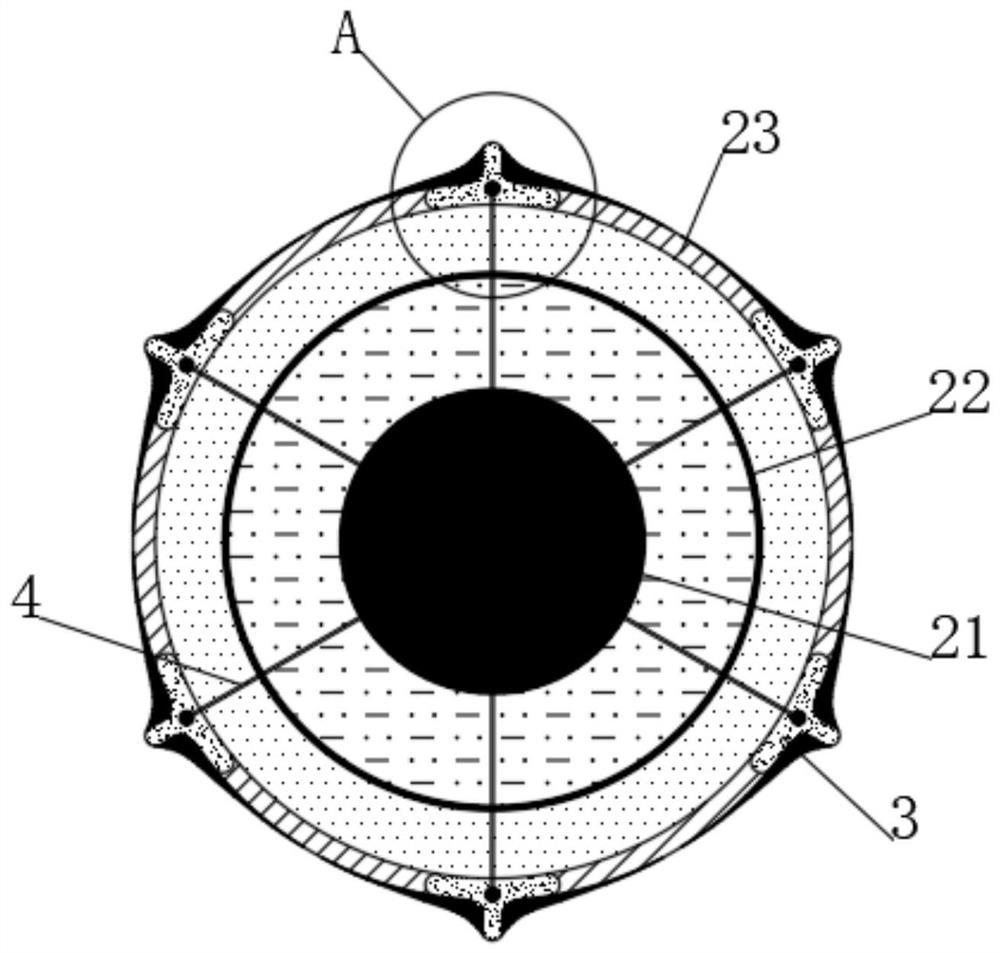

[0040] see Figure 2-3 The self-solidifying ball 2 includes an inner positioning ball 21, a plurality of bidirectional water guide rods 4 fixedly connected to the outer ends of the self-solidifying ball 2, a water storage self-expanding layer 22 located outside the inner positioning ball 21, and a water storage self-expanding layer 22 located outside the inner positioning ball 21. The self-contained block 23, the water storage self-expanding layer 22 and the inner positioning ball 21 are filled with water, the self-contained block 23 and the water-storage self-expansion layer 22 are filled with cement powder, and the two-way water guide rod 4 is fixed and runs through the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com