Polyurethane modified rock wool heat-insulation decoration board and continuous production device and method thereof

A polyurethane modification, thermal insulation decorative board technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high thermal conductivity of rock wool, difficulty in continuous production, low rock wool strength, etc. Low thermal conductivity, safe and reliable performance, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

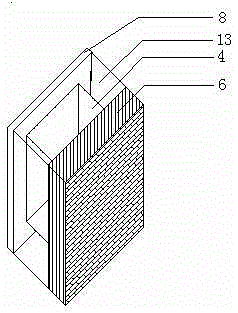

[0038] Reference to the polyurethane modified rock wool thermal insulation decorative board of this embodiment figure 1 . Including the decorative surface material 6 for decoration and fire prevention, the rock wool 4 that is attached to the back of the decorative surface material and the decorative surface material is integrated, and the decorative surface material 6, the rock wool 4, and the interface coil 8 are combined into one polyurethane The foam layer 13 and the interface coil 8 attached to the other side of the polyurethane foam layer 13. The decorative surface material 6 uses a thin stone veneer, and the thickness of the rock wool 4 is 5 cm. The specific operation steps of the production process are:

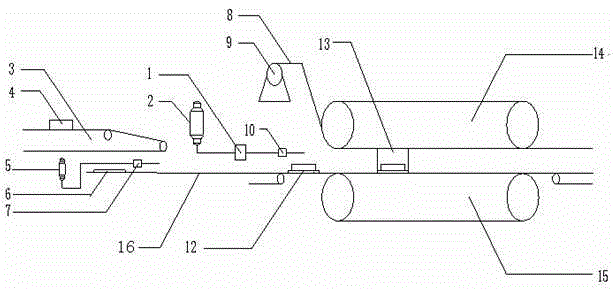

[0039] Adopt a continuous production line consisting of foaming machine 1, conveyor belt Ⅱ 3, preliminary bonding mechanism, conveyor belt Ⅰ 16, double-track laminator mechanism, decoiler 9, pouring mechanism, set conveyor belt Ⅱ 3, uncoiler 9, conveyor belt Ⅰ16. The link...

Embodiment 2

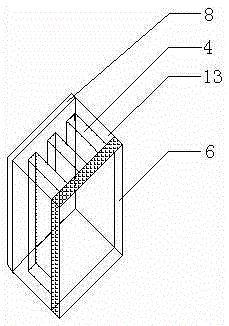

[0041] Reference Attachment for the polyurethane modified rock wool thermal insulation decorative board of this embodiment figure 2 . This embodiment is different from embodiment 1 in that: the decorative surface material 6 adopts an acrylic veneer, and the back of the acrylic board is compounded with three rock wool 4, the thickness of the rock wool 4 is 6 cm, and the interval between each rock wool is 3 cm. The specific process steps are:

[0042] Set the linkage speed of conveyor belt Ⅱ3, conveyor belt Ⅰ16, double-track laminator mechanism, and decoiler 9 to 4.5m / min. Place 1.2m×0.6m acrylic veneer on the conveyor belt Ⅰ16 and place three 1m× The 0.15m rock wool 4 is placed on the conveyor belt Ⅱ3, and the pressure of the gun head 7 of the glue spraying machine is adjusted to 16MPa and the flow rate is 208g / s. In the first process, the adhesive is evenly poured on the acrylic veneer to complete the initial bonding of the rock wool 4 and the acrylic veneer. In the second proc...

Embodiment 3

[0044] The polyurethane-modified rock wool thermal insulation decorative board of this embodiment is different from embodiment 1 in that the decorative surface material 6 is made of flexible stone, and the thickness of rock wool 4 is 10 cm. The specific operation steps of the production process are as follows:

[0045] Set the linkage speed of the conveyor belt Ⅱ3, conveyor belt Ⅰ16, double-track laminating mechanism, and coil unwinding mechanism 9 to 10m / min, and place the 0.9m×0.73m flexible stone on the conveyor belt Ⅰ16, 0.75m×0.6 The rock wool 4 of m is placed on the conveyor Ⅱ3, the pressure of the gun head 7 of the glue spraying machine is adjusted to 10MPa, and the flow rate is 500g / s. In the first process, the adhesive is evenly poured on the flexible stone to complete the preliminary bonding of the rock wool 4 and the flexible stone. In the second process, the polyurethane composite material with a material temperature of 40 ℃ is evenly poured on the rock wool 4 On the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com