Primer-topcoat polyurethane protective paint

A protective coating, polyurethane technology, applied in the field of paint and coating, can solve the problems of weak weather resistance and inability to adhere, and achieve the effects of excellent high resistance and quick drying, good wear resistance and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

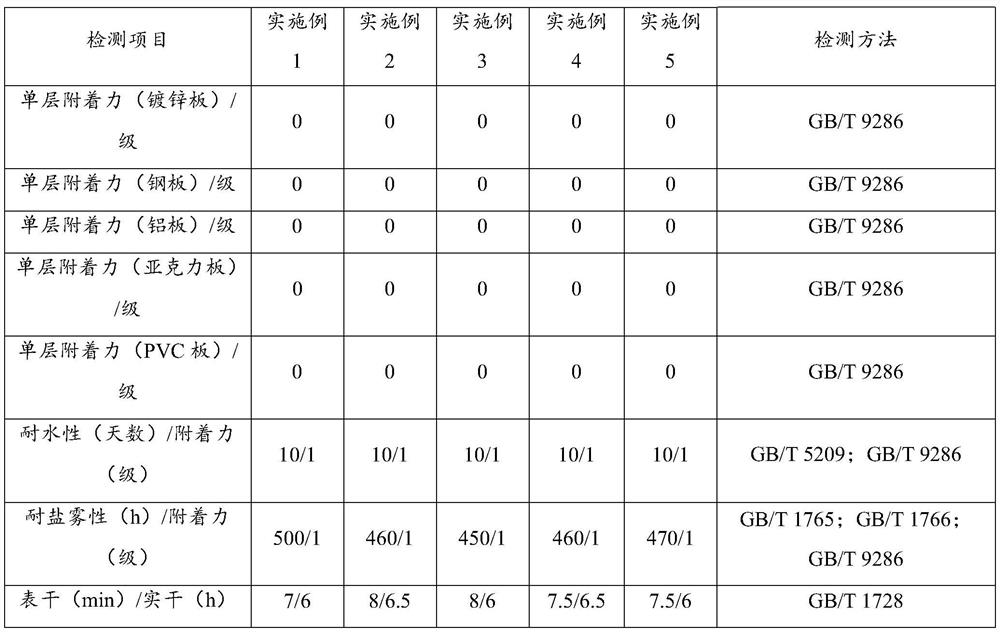

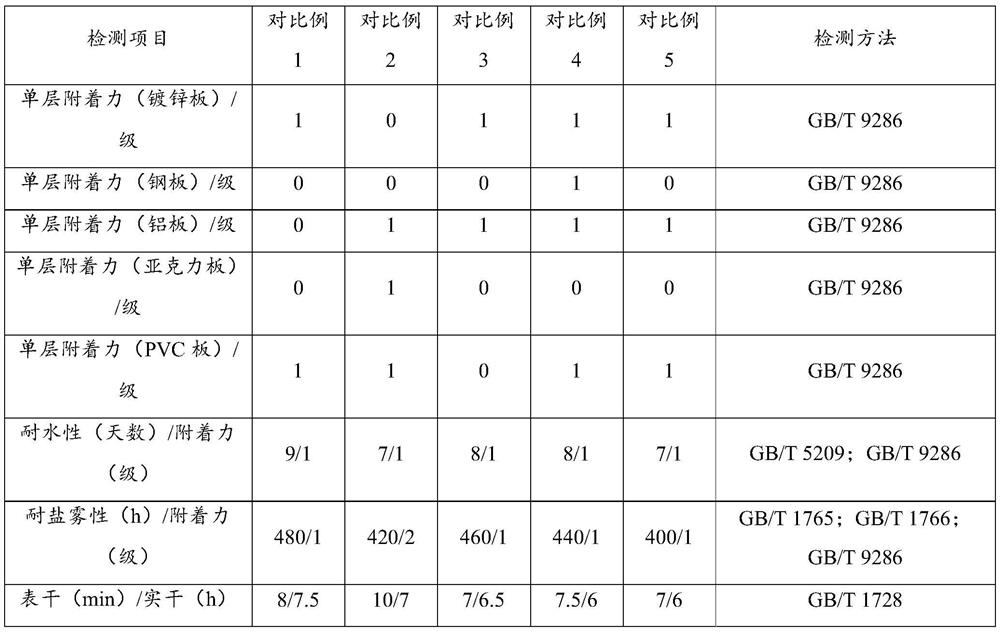

Examples

Embodiment 1

[0032]An embodiment of the bottom-side-one polyurethane protective coating of the present invention. The bottom-side-one polyurethane protective coating includes component A and component B, and component A includes the following components by weight: 46 parts Hydroxy acrylic resin, 1.5 parts of propylene glycol methyl ether acetate, 1.5 parts of BAC, 0.5 parts of dispersant, 1.5 parts of siloxane-based coupling agent, 1.5 parts of epoxy phosphate polymer, 5 parts of zinc molybdate modified pigment, 8 parts of activated siloxane modified nano mica powder, 5 parts of ultrafine talc powder, 3 parts of ultrafine barium sulfate, 15 parts of titanium dioxide, 0.3 parts of rheological agent, 11 parts of xylene and 0.2 parts of leveling agent; The B component includes the following components by weight: 42 parts of HDI curing agent, 29 parts of BAC and 29 parts of xylene; the mass ratio of the A component and the B component is 4:1; the modified hydroxy acrylic resin It is epoxy modified h...

Embodiment 2

[0039]An embodiment of the bottom-surface-integrated polyurethane protective coating of the present invention, the bottom-surface-integrated polyurethane protective coating includes component A and component B, and component A includes the following components by weight: 38 parts modified Hydroxy acrylic resin, 2 parts propylene glycol methyl ether acetate, 2 parts BAC, 0.5 parts dispersant, 3 parts siloxane-based coupling agent, 3 parts epoxy phosphate polymer, 3 parts zinc molybdate modified pigment, 15 parts of activated siloxane modified nano mica powder, 3 parts of ultrafine talc powder, 5 parts of ultrafine barium sulfate, 11 parts of titanium dioxide, 0.3 parts of rheological agent, 8 parts of xylene and 0.2 parts of leveling agent; The B component includes the following components by weight: 42 parts of HDI curing agent, 29 parts of BAC and 29 parts of xylene; the mass ratio of the A component and the B component is 4:1. The modified hydroxy acrylic resin is an epoxy modifie...

Embodiment 3

[0042]An embodiment of the bottom-surface-integrated polyurethane protective coating of the present invention, the bottom-surface-integrated polyurethane protective coating includes component A and component B, and component A includes the following components by weight: 52 parts modified Hydroxy acrylic resin, 1 part of propylene glycol methyl ether acetate, 1 part of BAC, 0.5 part of dispersant, 1 part of siloxane-based coupling agent, 1 part of epoxy phosphate polymer, 8 parts of zinc molybdate modified pigment, 6 parts of activated siloxane modified nanometer mica powder, 6 parts of ultrafine talc, 3 parts of ultrafine barium sulfate, 23 parts of titanium dioxide, 0.3 parts of rheological agent, 15 parts of xylene and 0.2 parts of leveling agent; The B component includes the following components by weight: 42 parts of HDI curing agent, 29 parts of BAC and 29 parts of xylene; the mass ratio of the A component and the B component is 4:1. The modified hydroxy acrylic resin is an ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com