Organosilicon-modified epoxy resin for robot insulation clothing and preparation method thereof

A technology of epoxy resin and organosilicon, which is applied in the field of organosilicon modified epoxy resin and its preparation, can solve the problem of affecting the mechanical properties and other properties of epoxy resin, poor compatibility of organosilicon and epoxy resin, mixing Inhomogeneity and other problems to achieve the effect of preventing pollution flashover accidents, good water repellency and water repellency, and reducing cleaning construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

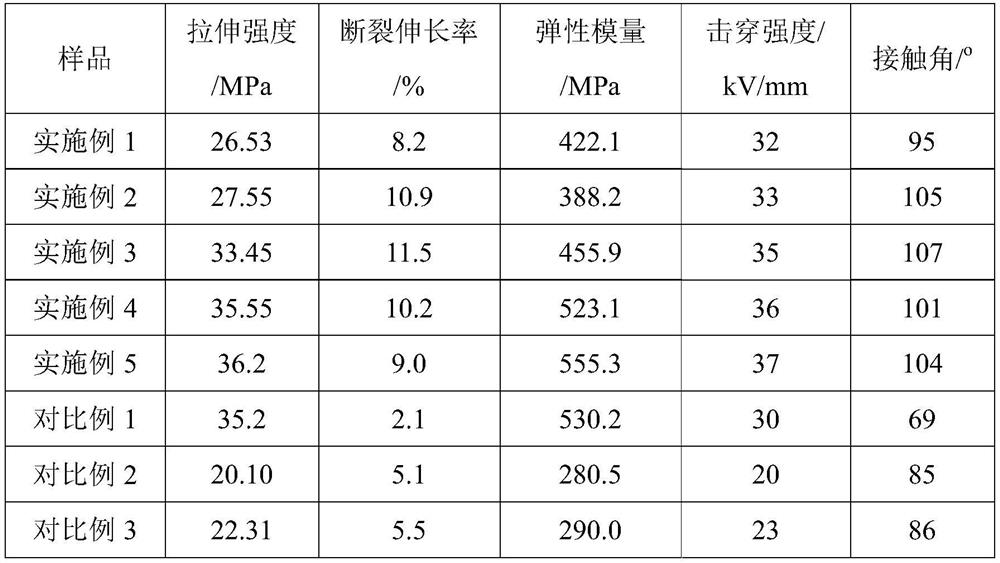

Examples

Embodiment 1

[0023] A silicone-modified epoxy resin for robot insulating clothing, comprising the following components in parts by weight: 60 parts of glycidyl hexahydrophthalate, 1 part of epoxy-terminated silicone oil, and 1 part of polyether-modified silicone oil parts, 60 parts of tetrahydrophthalic anhydride, 50 parts of 500 nm glass fiber, 5 parts of aluminum hydroxide, 10 parts of butyl glycidyl ether, 0.5 part of tertiary amine accelerator, and 1 part of iron oxide red.

[0024] The above-mentioned silicone-modified epoxy resin for robot insulating clothing is obtained by the following preparation method:

[0025] (1) evacuating glycidyl hexahydrophthalate, epoxy-terminated silicone oil, polyether-modified silicone oil, glass fiber, and aluminum hydroxide in a kneader to 0.04MP and mixing at room temperature for 3h to obtain component A;

[0026] (2) vacuumize tetrahydrophthalic anhydride, butyl glycidyl ether, tertiary amine accelerator and red iron oxide in a kneader to 0.04MP ro...

Embodiment 2

[0029] A silicone-modified epoxy resin for robot insulating clothing, comprising the following components by weight: 180 parts of glycidyl hexahydrophthalate, 30 parts of epoxy-terminated silicone oil, and 5 parts of polyether-modified silicone oil parts, 180 parts of tetrahydrophthalic anhydride, 200 parts of 5 μm glass fibers, 20 parts of aluminum hydroxide, 15 parts of butyl glycidyl ether, and 6 parts of imidazole accelerators.

[0030] The above-mentioned silicone-modified epoxy resin for robot insulating clothing is obtained by the following preparation method:

[0031] (1) evacuating glycidyl hexahydrophthalate, epoxy-terminated silicone oil, polyether-modified silicone oil, glass fiber, and aluminum hydroxide in a kneader to 0.04MP and mixing at room temperature for 5h to obtain component A;

[0032] (2) vacuumize tetrahydrophthalic anhydride, butyl glycidyl ether and imidazole accelerator in the kneader to 0.04MP at room temperature and mix for 5h, to component B;

...

Embodiment 3

[0035]A silicone-modified epoxy resin for robot insulating clothing, comprising the following components in parts by weight: 100 parts of glycidyl hexahydrophthalate, 10 parts of epoxy-terminated silicone oil, and 2 parts of polyether-modified silicone oil parts, 100 parts of methyltetrahydrophthalic anhydride, 50 parts of 2μm carbon fiber, 50 parts of 5μm fumed silica, 10 parts of aluminum hydroxide, 12 parts of butyl glycidyl ether, 3 parts of tertiary amine accelerator, 1 part of titanium dioxide .

[0036] The above-mentioned silicone-modified epoxy resin for robot insulating clothing is obtained by the following preparation method:

[0037] (1) glycidyl hexahydrophthalate, epoxy-terminated silicone oil, polyether modified silicone oil, carbon fiber, fumed silica and aluminum hydroxide were evacuated in a kneader to 0.03MP and mixed at room temperature for 3h, to obtain component A;

[0038] (2) Methyltetrahydrophthalic anhydride, butyl glycidyl ether, tertiary amine acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com