Method for synthesizing novel spinnable polyborazane precursor in one pot

A technology of polyborazane and synthesis method, applied in textiles and papermaking, chemical characteristics of fibers, etc., can solve the problems of difficult spinning, low ceramic yield, high system viscosity, etc., and achieve excellent spinnability and low oxygen content. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for one-pot synthesis of novel spinnable polyborazane precursors, including:

[0049] (1) prepare MAB monomer and RAB monomer;

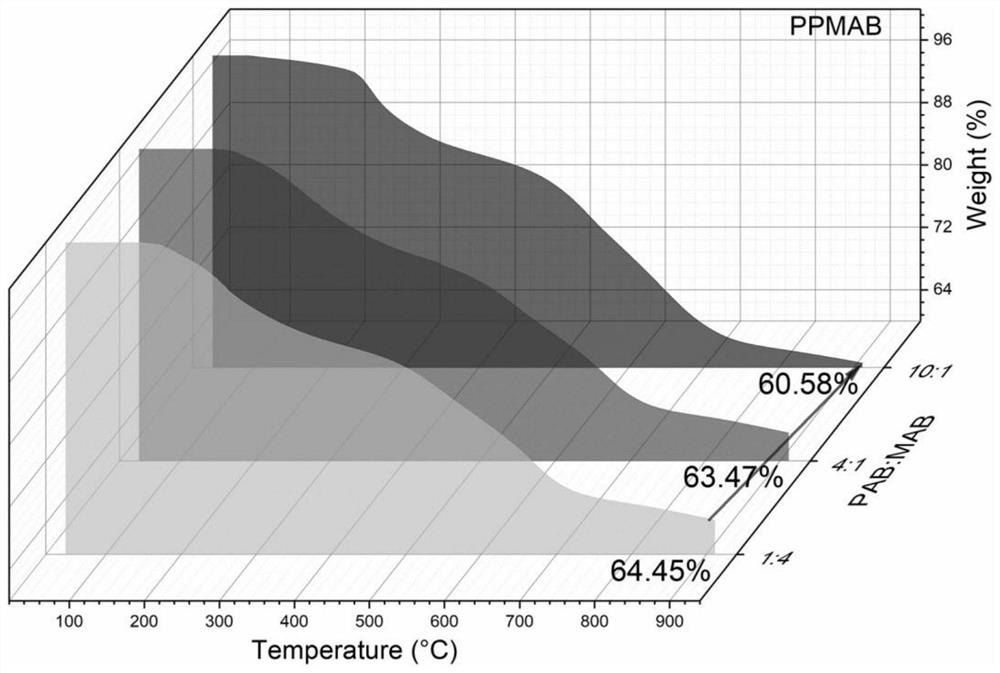

[0050] S11: Determine the copolymerization ratio of MAB and RAB in the target product to 10:1;

[0051] S12: According to the copolymerization ratio of 10:1, set the molar ratio of TCB, n-propylamine and methylamine to 11:1:32;

[0052]S13: Dissolve TCB in toluene, add triethylamine and n-propylamine under the condition of <-10°C, stir for 1 hour, then feed methylamine gas, continue stirring for 8 hours under the condition of <-10°C, and then lower the temperature from < Warm up to room temperature at -10°C, stir for 8 hours, and vacuum filter to obtain a colorless mixed monomer liquid of MAB and RAB;

[0053] (2) Preparation of novel spinnable polyborazane (PRMAB) precursor;

[0054] The colorless mixed monomer liquid of MAB and RAB was heated up to 140°C, kept at 140°C for 2h, and cooled naturally to room...

Embodiment 2

[0057] This embodiment provides a method for one-pot synthesis of novel spinnable polyborazane precursors, including:

[0058] (1) prepare MAB monomer and RAB monomer;

[0059] S11: Determine the copolymerization ratio of MAB and RAB in the target product to 4:1;

[0060] S12: According to the copolymerization ratio of 4:1, set the molar ratio of TCB, n-propylamine and methylamine to 5:1:14;

[0061] S13: Dissolve TCB in a mixture of toluene and xylene, add triethylamine and n-propylamine at <-10°C, stir for 2 hours, then inject methylamine gas, and continue stirring for 6 hours at <-10°C , then raise the temperature from <-10°C to room temperature, stir for 6 hours, and vacuum filter to obtain a colorless mixed monomer liquid of MAB and RAB;

[0062] (2) Preparation of novel spinnable polyborazane (PRMAB) precursor;

[0063] The colorless mixed monomer liquid of MAB and RAB was heated up to 140°C, kept at 140°C for 4h, and cooled naturally to room temperature to obtain a n...

Embodiment 3

[0066] This embodiment provides a method for one-pot synthesis of novel spinnable polyborazane precursors, including:

[0067] (1) prepare MAB monomer and RAB monomer;

[0068] S11: Determine the copolymerization ratio of MAB and RAB in the target product to 1:4;

[0069] S12: According to the copolymerization ratio of 4:1, set the molar ratio of TCB, n-propylamine and methylamine to 5:4:11;

[0070] S13: Dissolve TCB in chlorobenzene, add triethylamine and n-propylamine under the condition of <-10°C, stir for 3 hours, then introduce methylamine gas, continue stirring for 4 hours under the condition of <-10°C, and then lower the temperature from <-10°C, warm up to room temperature, stir for 6 hours, and vacuum filter to obtain a colorless mixed monomer liquid of MAB and RAB;

[0071] (2) Preparation of novel spinnable polyborazane (PRMAB) precursor;

[0072] The colorless mixed monomer liquid of MAB and RAB was heated to 180°C, kept at 180°C for 6h, and cooled naturally to ...

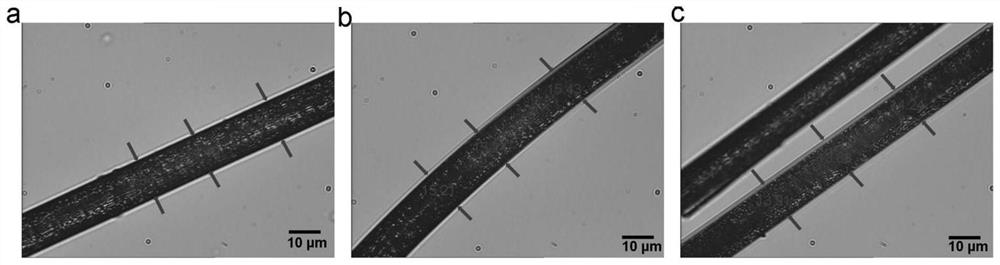

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com