Nickel sulfide series hydrogenation catalyst and pyrolysis gasoline hydrotreatment method

A hydrogenation catalyst, nickel sulfide-based technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbon oil treatment products, etc., can solve catalyst surface coking, nitrogen content, diolefins High impurity content, device shutdown and other problems, achieve good activity and stability, inhibit hydrogenation saturation of aromatics, and controllable acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

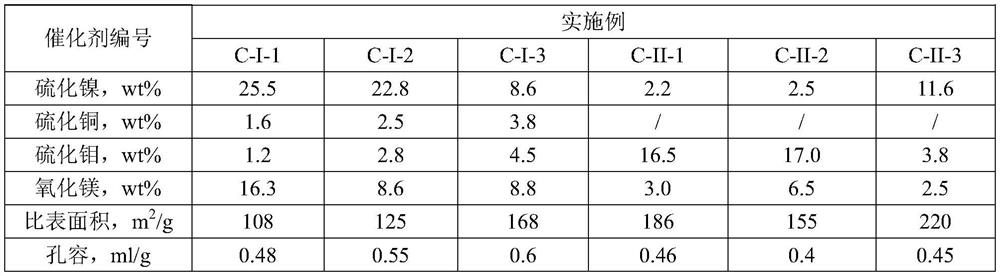

[0022] Embodiment 1 Preparation of one-stage nickel sulfide hydrogenation catalyst

[0023] Measured nickel nitrate, copper nitrate, sodium molybdate, magnesium nitrate, aluminum sulfate and aminotriacetic acid are dissolved to prepare metal salt solution I, and sodium carbonate and thiourea are dissolved to prepare solution II. Add 10L deionized water into a 100L reactor, adjust the stirring speed to 50 rpm, heat to 70°C, add solution I and solution II into the reactor in parallel, control the pH at 6-8, and control the feeding time at 1 hour , and then continue to react for 1 hour, then seal the reactor and carry out hydrothermal in-situ vulcanization for 2.5 hours. After the reaction materials were washed and filtered, the filter cake was directly extruded into strips and cut into balls, dried at 120°C for 6 hours under a nitrogen protective atmosphere, and calcined at 380°C for 3 hours to obtain a finished nickel sulfide hydrogenation catalyst, marked as C-I-X. The cataly...

Embodiment 2

[0024] Embodiment 2 Preparation of two-stage nickel sulfide hydrogenation catalyst

[0025] The preparation steps of the two-stage nickel sulfide-based hydrogenation catalyst are the same as in Example 1, and are marked as C-II-X. The catalyst is a toothed spherical particle with a particle size of 2.0-2.5 mm, and its composition and physical properties are shown in Table 1.

Embodiment 3

[0028] The hydrogenation activity evaluation of embodiment 3 catalyst

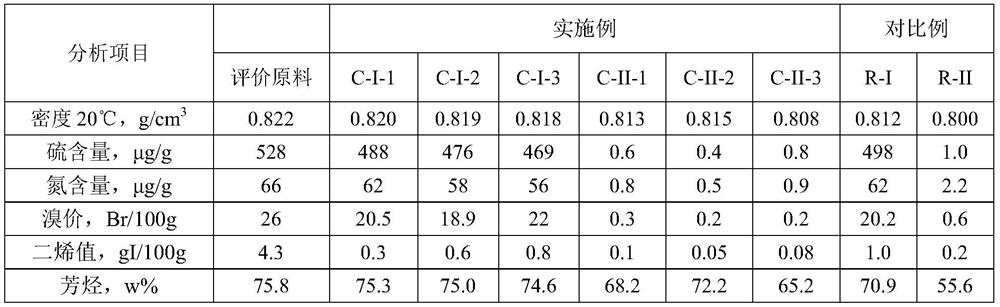

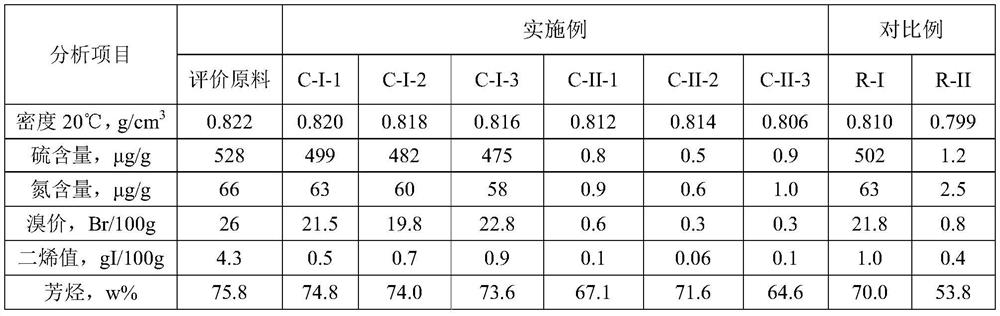

[0029] Catalysts were evaluated for pyrolysis gasoline hydrotreating activity on a 100ml hydrogenation reactor. The hydrogenation reactor used microporous dispersed internals, and hydrogen gas entered the pyrolysis gasoline stream after passing through the microporous dispersed internals, and then contacted with the catalyst. The raw material oil for evaluation is catalytic cracking gasoline produced by industrial equipment, and its density is 0.822g / cm 3 , the sulfur content is 528μg / g, the nitrogen content is 66μg / g, the bromine value is 26gBr / 100g, the diene value is 4.3gI / 100g, the olefin content is 15.6V%, the aromatic hydrocarbon is 75.8w%, and the distillation range is 43-188°C.

[0030] Fill the one-stage nickel sulfide-based hydrogenation catalyst A and the second-stage nickel sulfide-based hydrogenation catalyst B into two hydrogenation reactors connected in series respectively. The catalyst load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com