A (ti, zr)-nb-o alloy with superconducting properties and preparation method thereof

A ti-zr-nb-o, superconducting performance technology, applied in the field of material research, can solve problems such as low critical superconducting transition temperature, and achieve the effects of improving comprehensive performance, ensuring stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

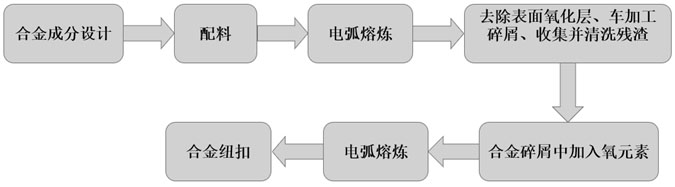

[0031] A method for preparing a 39.9Ti-60Nb-0.1O alloy with superconducting properties (for the preparation flow chart, see figure 1 ), which includes the following steps:

[0032] Step 1. Ingredients:

[0033] According to the 39.9Ti-60Nb-0.1O alloy (that is, the mass percentage of each element of the alloy is Ti 39.9%, Nb 60% and O 0.1%), calculate and weigh the corresponding raw material quality, where O is TiO 2 Added in the form of O content in TiO 2 The conversion percentage content is calculated, and the ingredients are all measured according to the mass percentage. The weighing of each raw material adopts an electronic balance with an accuracy of 0.0001g; Ti particles, Nb particles and TiO 2 Particles were weighed 9.3760g, 15.0000g, 0.6240g;

[0034] Step 2, melting and preparing 39.9Ti-60Nb alloy:

[0035] Put the precise ratio of Ti and Nb particle raw materials in step 1 into the non-consumable vacuum electric arc furnace, and evacuate to 3pa; open the high-puri...

Embodiment 2

[0043] A method for preparing a 44.5Ti-55Nb-0.5O alloy with superconducting properties, comprising the steps of:

[0044] Step 1, batching: with reference to embodiment 1;

[0045] Step 2, melting and preparing 44.5Ti-55Nb alloy:

[0046] Put the Ti and Nb particle raw materials with precise ratio in step 1 into the non-consumable vacuum electric arc furnace, first evacuate to 3pa, open the high-purity argon valve, inhale 2-3 times, and continue to ventilate as protection; Under gas protection atmosphere, control the arc to move to 2-5mm above the material, slowly increase the arc intensity to 265A / s, smelt for 4min, and repeat smelting 6 times; cool to room temperature, and obtain alloy block 1;

[0047] Step 3, remove the surface oxide layer, car processing debris and clean: refer to Example 1;

[0048] Step 4. Preparation of 44.5Ti-55Nb-0.5O master alloy

[0049] The alloy nugget-crust that step 3 obtains and the TiO that step 1 takes by weighing 2 The particles are put...

Embodiment 3

[0053] A method for preparing a 46.4Ti-53Nb-0.6O alloy with superconducting properties, comprising the steps of:

[0054] Step 1, batching: with reference to embodiment 1;

[0055] Step 2, melting and preparing 46.4Ti-53Nb alloy:

[0056] Put the Ti and Nb particle raw materials with precise ratio in step 1 into the non-consumable vacuum electric arc furnace, first evacuate to 3pa, open the high-purity argon valve, inhale 2-3 times, and continue to ventilate as protection; Under gas protection atmosphere, control the arc to move to 2-5mm above the material, slowly increase the arc intensity to 265A / s, smelt for 4min, and repeat smelting 6 times; cool to room temperature, and obtain alloy block 1;

[0057] Step 3, remove the surface oxide layer, car processing debris and clean: refer to Example 1;

[0058] Step 4. Preparation of 46.4Ti-53Nb-0.6O master alloy

[0059] The alloy nugget-crust that step 3 obtains and the TiO that step 1 takes by weighing 2 The particles are put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com