Oxygen-free copper, preparation method and application

An oxygen-free copper and alloying element technology, applied in the field of preparation and oxygen-free copper, can solve the problems of product macroscopic surface roughness, coarse recrystallized grains, shortened service life, etc., to increase melt fluidity and reduce melt viscosity. , the effect of purifying the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] This example provides a kind of oxygen-free copper and preparation method thereof, and concrete steps are as follows:

[0115] (1) Weigh Cu-Zr master alloy, Cu-Sr master alloy, Cu-Ce master alloy, Cu-Yb master alloy block and Electrolytic copper plate.

[0116] (2) In the graphite crucible, place a weighed electrolytic copper plate, a uniformly mixed intermediate alloy block, a refining agent accounting for 5% of the sum of electrolytic copper and alloy mass, and a 20cm covering agent (charcoal block and graphite crucible) from bottom to top. pink).

[0117] (3) in N 2 Under +CO gas atmosphere, melt the material in step (2) with an intermediate frequency induction furnace at a melting temperature of 1200°C.

[0118] (4) Under a protective atmosphere, cast the melt with uniform composition in step (3) at 1130°C.

[0119] (5) Under a protective atmosphere, the ingot obtained in step (4) is subjected to a homogenization treatment at a treatment temperature of 600° C. f...

Embodiment 2

[0124] This example provides an oxygen-free copper and its preparation method. The difference between the specific steps and Example 1 is: in step (1), the addition amount of alloying elements is 20ppm Zr, 20ppm Sr, 40ppm Ce, and 80ppm Yb.

[0125] In this example, oxygen-free copper sample 2 was prepared.

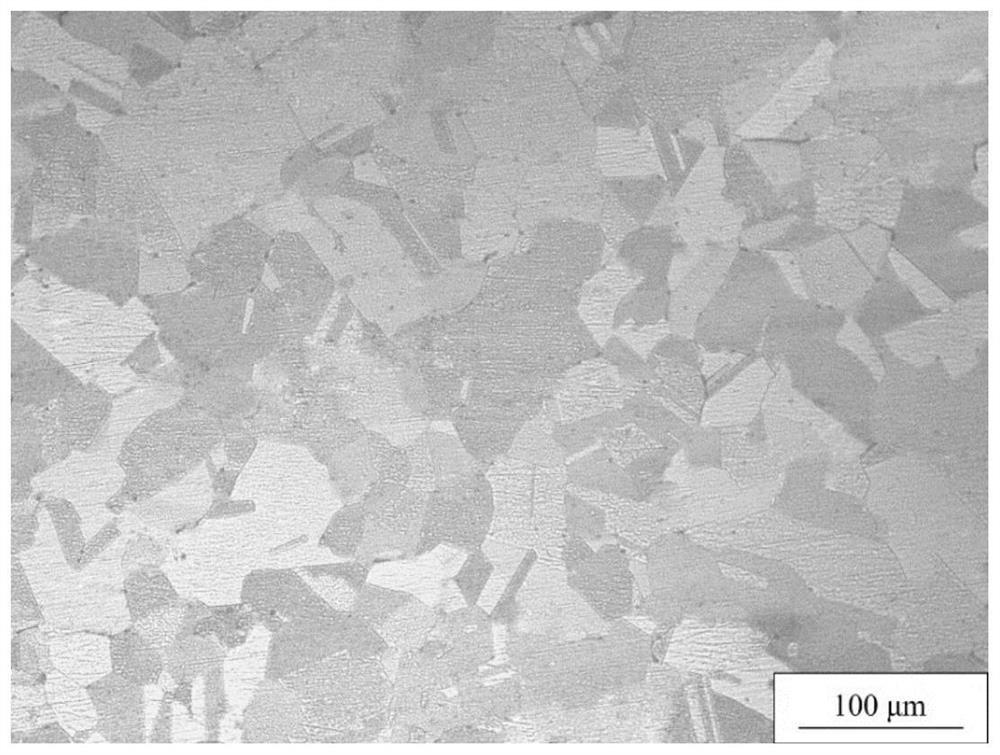

[0126] The metallographic structure of oxygen-free copper sample 2 is as follows figure 2 shown.

Embodiment 3

[0128] This example provides an oxygen-free copper and its preparation method. The difference between the specific steps and Example 1 is: in step (1), the addition amount of alloying elements is 15ppm Zr, 15ppm Sr, 15ppm Ce, and 40ppm Yb.

[0129] In this example, an oxygen-free copper sample 3 was prepared.

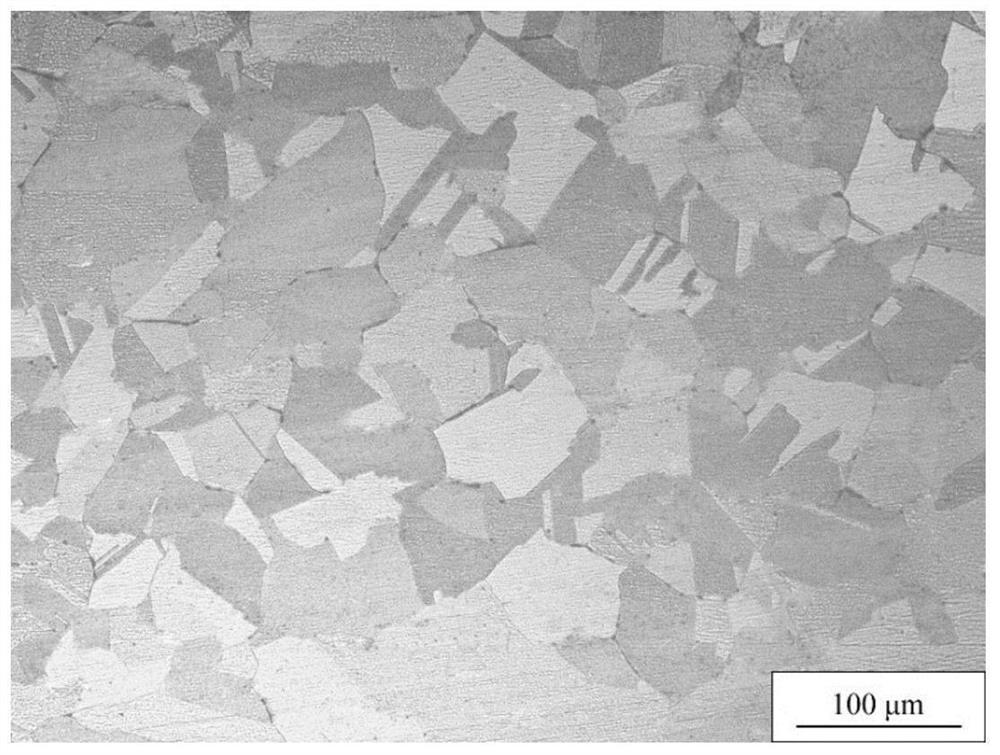

[0130] The metallographic structure of oxygen-free copper sample 3 is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com